-

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23 -

×

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

2 × $2,225.47

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

2 × $2,225.47 -

×

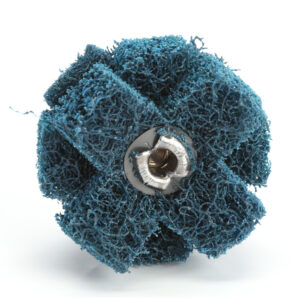

Dynabrade 90873 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $2.30

Dynabrade 90873 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $2.30 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39 -

×

3M 29822, Sanding Screen, 120 Grit, 20 in x NH, 7100160250

12 × $8.00

3M 29822, Sanding Screen, 120 Grit, 20 in x NH, 7100160250

12 × $8.00 -

×

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $1,012.00

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $1,012.00 -

×

3M 20930, PSA Cloth Disc 348D, P120 X-weight, 1 in x NH, Die 100N, 7000118916

500 × $0.39

3M 20930, PSA Cloth Disc 348D, P120 X-weight, 1 in x NH, Die 100N, 7000118916

500 × $0.39 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52 -

×

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 175u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 175u

12 × $7.60 -

×

3M 13372, Scotch-Brite Star, 3 in A CRS LS, 7000120967

100 × $6.76

3M 13372, Scotch-Brite Star, 3 in A CRS LS, 7000120967

100 × $6.76 -

×

3M Dirt Trap Material Dispenser, 7100003285

1 × $227.35

3M Dirt Trap Material Dispenser, 7100003285

1 × $227.35 -

×

3M 77116, Scotch Brite Roloc Deburr & Finish PRO Unitized Wheel, DP-UR, 4C Medium+, TR, 3 in x 1/4 in x NH, 7010295274

40 × $11.94

3M 77116, Scotch Brite Roloc Deburr & Finish PRO Unitized Wheel, DP-UR, 4C Medium+, TR, 3 in x 1/4 in x NH, 7010295274

40 × $11.94 -

×

3M 14345, Marine Adhesive Sealant 4000 UV, Black, 3 oz Tube, 7010367954, 6/Case

6 × $15.34

3M 14345, Marine Adhesive Sealant 4000 UV, Black, 3 oz Tube, 7010367954, 6/Case

6 × $15.34 -

×

3M 13800, Scotch-Brite Star, 1-1/2 in A VFN LS, 7000120969

100 × $3.24

3M 13800, Scotch-Brite Star, 1-1/2 in A VFN LS, 7000120969

100 × $3.24 -

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67 -

×

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51 -

×

3M 17181, Scotch-Brite Roloc Unitized Wheel Pack 987S, 2 in, 7000144150

5 × $72.45

3M 17181, Scotch-Brite Roloc Unitized Wheel Pack 987S, 2 in, 7000144150

5 × $72.45 -

×

3M 69602, Cloth Belt 777F, 60 YF-weight, 1 in x 11 in, Sine-lok, Full-flex, 7010295223, 500 per case

500 × $1.05

3M 69602, Cloth Belt 777F, 60 YF-weight, 1 in x 11 in, Sine-lok, Full-flex, 7010295223, 500 per case

500 × $1.05 -

×

3M 55925, Water Contact Indicator Tape 5557, White, 12 In x 180 Yd, 1Roll/Case, 7000001270

1 × $10,730.51

3M 55925, Water Contact Indicator Tape 5557, White, 12 In x 180 Yd, 1Roll/Case, 7000001270

1 × $10,730.51 -

×

3M 20274, Neoprene Contact Adhesive 10, Light Yellow, 1 Gallon Can, 7000144610, 4/case

4 × $112.37

3M 20274, Neoprene Contact Adhesive 10, Light Yellow, 1 Gallon Can, 7000144610, 4/case

4 × $112.37 -

×

3M 29827, Sanding Screen, 120 Grit, 19 in x NH, 7100160249

22 × $8.00

3M 29827, Sanding Screen, 120 Grit, 19 in x NH, 7100160249

22 × $8.00 -

×

3M 28217, Cubitron II Roloc Disc 984F, 60+ YF-weight, TR, 3 in, Die R300V, 7010326790

200 × $1.78

3M 28217, Cubitron II Roloc Disc 984F, 60+ YF-weight, TR, 3 in, Die R300V, 7010326790

200 × $1.78 -

×

Air Turbine Tools 310RDM - 1/4" Router Hand Tool Series, 40,000RPM, 33442

1 × $950.00

Air Turbine Tools 310RDM - 1/4" Router Hand Tool Series, 40,000RPM, 33442

1 × $950.00 -

×

3M 08302, Ultrapro Autobody Sealant, Clear, 5 oz Tube, 7000120449, 6 per case

6 × $30.54

3M 08302, Ultrapro Autobody Sealant, Clear, 5 oz Tube, 7000120449, 6 per case

6 × $30.54 -

×

Standard Abrasives 265024, Buff and Blend Cross Buff HP, A/O Very Fine, 1 in x 3/8 in x 2 Ply x 8-32, 7010310168

10 × $1.56

Standard Abrasives 265024, Buff and Blend Cross Buff HP, A/O Very Fine, 1 in x 3/8 in x 2 Ply x 8-32, 7010310168

10 × $1.56

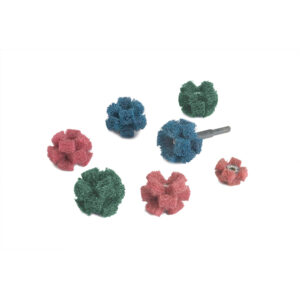

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

$4.57

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.