-

×

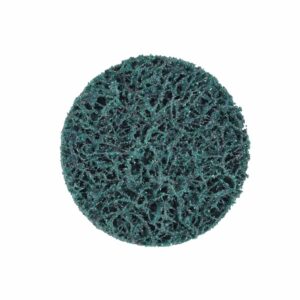

3M 15913, Scotch-Brite Roloc Disc High Strength, TR, 2 in X NH A Medium, 7000000710

200 × $1.72

3M 15913, Scotch-Brite Roloc Disc High Strength, TR, 2 in X NH A Medium, 7000000710

200 × $1.72 -

×

Dynabrade 97566 1/4" Safety Coupler, Female

1 × $17.88

Dynabrade 97566 1/4" Safety Coupler, Female

1 × $17.88 -

×

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,448.42

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,448.42 -

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14 -

×

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73 -

×

3M 29848, Sanding Screen, 180 Grit, 15 in x NH, 7100160815

12 × $4.03

3M 29848, Sanding Screen, 180 Grit, 15 in x NH, 7100160815

12 × $4.03 -

×

3M 29822, Sanding Screen, 120 Grit, 20 in x NH, 7100160250

12 × $8.00

3M 29822, Sanding Screen, 120 Grit, 20 in x NH, 7100160250

12 × $8.00 -

×

3M 29837, Sanding Screen, 180 Grit, 17 in x NH, 7100160762

12 × $5.83

3M 29837, Sanding Screen, 180 Grit, 17 in x NH, 7100160762

12 × $5.83 -

×

3M 29823, Sanding Screen, 100 Grit, 20 in x NH, 7100160246

12 × $9.25

3M 29823, Sanding Screen, 100 Grit, 20 in x NH, 7100160246

12 × $9.25 -

×

3M 14502 Scotch-Brite Surface Conditioning Belt, 3/8 in x 13 in, A MED, 7100103026

20 × $3.56

3M 14502 Scotch-Brite Surface Conditioning Belt, 3/8 in x 13 in, A MED, 7100103026

20 × $3.56

Tackle Hard-To-Reach Areas

Scotch-Brite™ Star has six spindles attached to an eyelet. Made with nonwoven technology, the spindles are spongy, buoyant and flexible. Consequently, they can bend and move to accommodate the insides of metal tubes and pipes. Scotch-Brite™ Star comes in small sizes, with the smallest diameter being 1-1/2 inches and the largest diameter being 4 inches. The small size supplements the spongy spindles, helping the abrasive fit inside hard-to-reach areas. These stars lightly deburr and blend contours and ridges without gouging or marring the surface, helping to reduce scraps and rework. Stars may be used on a variety of metals: stainless steel, aluminum, carbon steel, cast iron, titanium and non-ferrous metals.

Ease of Use

The Scotch-Brite™ Star may be used with 3M mandrel 944 (sold separately).The threaded attachments fasten to mandrel 944 for safe use on a die grinder. Scotch-Brite™ Star requires low pressure when used at correct operating speeds. [Reviewer please confirm].The abrasive is available in coarse (CRS) and very fine (VFN) grades. Use a coarse abrasive when refining a deep grind line/scratch or when a more aggressive scratch pattern is desired, and use a fine abrasive when a soft, fine scratch pattern is desired. Scotch-Brite™ Star comes in packs of 50 or 100 stars per case to minimize the need for ordering replacements and to help reduce operating costs.

The Many Benefits of Open Web Abrasives

Nonwoven technology makes our Scotch-Brite™ industrial abrasives unique. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance, and extremely long service life. Scotch-Brite products not only enhance productivity, but also increase operator safety. By reducing the need for cleaning chemicals and pastes, and replacing wire brushes that can break off and cause injury. From aesthetic finishing to deburring and more, Scotch-Brite abrasives work fast and deliver consistent results, part after part.