-

×

3M 71346, 675L, 1" X 120", 125u, Diamond Microfinishing Film Belts, 7010534823

1 × $97.89

3M 71346, 675L, 1" X 120", 125u, Diamond Microfinishing Film Belts, 7010534823

1 × $97.89 -

×

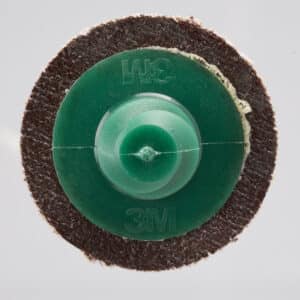

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67 -

×

3M 76630, Roloc Disc 777F, 50 YF-weight, TR, 2 in, Die R200P, 7000045627

200 × $1.18

3M 76630, Roloc Disc 777F, 50 YF-weight, TR, 2 in, Die R200P, 7000045627

200 × $1.18 -

×

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06 -

×

3M 34675, 641WY, 1" X 30", 400 Mesh, Diamond Cloth Belts, 7100111369

3 × $0.00

3M 34675, 641WY, 1" X 30", 400 Mesh, Diamond Cloth Belts, 7100111369

3 × $0.00 -

×

ACS Diamond Cloth Belt, CX1250 3" X 90" 125U

2 × $171.30

ACS Diamond Cloth Belt, CX1250 3" X 90" 125U

2 × $171.30

3M 52980, 663FC, 2″ X 90″, 20u, Diamond Trizact Belts, 7100205967, 2/Box

$958.50

Made to Order – 14 Day Lead Time

- Can cut hard to grind materials up to 70% faster than bonded wheels

- Delivers consistent grinding performance while reducing the likelihood of grinding chatter

- YF-weight backing supports medium to high pressure grinding applications

- Great for stock removal

Our 3M™ Trizact™ Diamond Cloth Belt 663FC represents the “next generation” in abrasive technology. It combines the predictable dimensioning of bonded wheels with the speed, consistency and ease of use of 3M abrasive belts. This unique hybrid helps you achieve a smoother finish in less time.