-

×

Dynabrade 78860 Crimped Wire Radial Wheel Brush 2" Dia. x .006 x 7/16" Steel

1 × $16.96

Dynabrade 78860 Crimped Wire Radial Wheel Brush 2" Dia. x .006 x 7/16" Steel

1 × $16.96 -

×

Dynabrade 96086 Spring Pin

1 × $1.93

Dynabrade 96086 Spring Pin

1 × $1.93 -

×

Dynabrade 96174 Motor Tune-Up Kit

1 × $163.63

Dynabrade 96174 Motor Tune-Up Kit

1 × $163.63 -

×

Dynabrade 93609 1" Dia. x 3/8", 3-48 Female Center Thread, 60 Grit A/O, 8 Ply, J-DynaCut Cross Pad, 100/pack

100 × $1.34

Dynabrade 93609 1" Dia. x 3/8", 3-48 Female Center Thread, 60 Grit A/O, 8 Ply, J-DynaCut Cross Pad, 100/pack

100 × $1.34 -

×

Dynabrade 01185 Vane Set (4pk)

1 × $24.78

Dynabrade 01185 Vane Set (4pk)

1 × $24.78 -

×

Dynabrade 96541 Tune-Up Kit for .4 hp Motor, Rear Exhaust

1 × $185.84

Dynabrade 96541 Tune-Up Kit for .4 hp Motor, Rear Exhaust

1 × $185.84 -

×

Dynabrade 93534 3" Mandrel for Sanding Stars, 3-48 Male Thread

1 × $9.25

Dynabrade 93534 3" Mandrel for Sanding Stars, 3-48 Male Thread

1 × $9.25 -

×

Dynabrade 79108 1/2" W x 12" L 60 Grit DynaCut Premium Ceramic Belts, 50/pack

100 × $2.45

Dynabrade 79108 1/2" W x 12" L 60 Grit DynaCut Premium Ceramic Belts, 50/pack

100 × $2.45 -

×

Dynabrade 79513 1/2" W x 12" L Medium DynaBrite Plus Surface Conditioning Belt, 10/pack

10 × $7.45

Dynabrade 79513 1/2" W x 12" L Medium DynaBrite Plus Surface Conditioning Belt, 10/pack

10 × $7.45 -

×

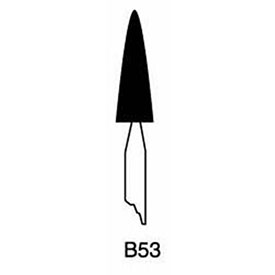

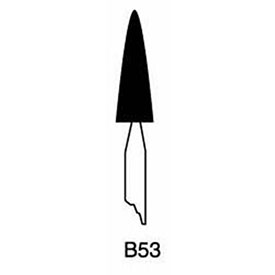

Dynabrade 78710 5/16" x 5/8"-B53 Dynacut A/O Mounted Point, 5/pack

5 × $1.46

Dynabrade 78710 5/16" x 5/8"-B53 Dynacut A/O Mounted Point, 5/pack

5 × $1.46 -

×

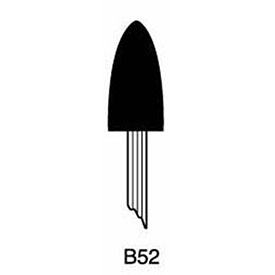

Dynabrade 78724 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46

Dynabrade 78724 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46 -

×

Dynabrade 90549 1/2" W x 44" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $2.54

Dynabrade 90549 1/2" W x 44" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $2.54 -

×

Dynabrade 95850 - 1/4" Female Coupler with 1/4" Female Plug Assembly

1 × $30.38

Dynabrade 95850 - 1/4" Female Coupler with 1/4" Female Plug Assembly

1 × $30.38 -

×

Dynabrade 78538 3/4"Dia. 2-Set, 3-48 Female Center Thread, 80 Grit, Dynacut A/O Overlap Slotted Disc, 100/pack

100 × $1.10

Dynabrade 78538 3/4"Dia. 2-Set, 3-48 Female Center Thread, 80 Grit, Dynacut A/O Overlap Slotted Disc, 100/pack

100 × $1.10 -

×

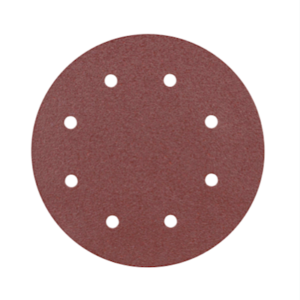

Dynabrade 91248 8" Dia. x 320 Grit A/O Vacuum PSA DynaCut Disc, 25/Box

25 × $2.75

Dynabrade 91248 8" Dia. x 320 Grit A/O Vacuum PSA DynaCut Disc, 25/Box

25 × $2.75 -

×

Dynabrade 64674 Filter Cartridge

1 × $75.74

Dynabrade 64674 Filter Cartridge

1 × $75.74 -

×

Dynabrade 64700 36" (91 cm) W x 72" (183 cm) L Downdraft Sanding Table, 115 V (AC)

1 × $5,914.69

Dynabrade 64700 36" (91 cm) W x 72" (183 cm) L Downdraft Sanding Table, 115 V (AC)

1 × $5,914.69 -

×

Dynabrade 64400 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Down Exhaust

1 × $27,619.39

Dynabrade 64400 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Down Exhaust

1 × $27,619.39 -

×

Dynabrade 52712 2" (51 mm) Dia. Right Angle Depressed Center Wheel Grinder, .4 HP, 20,000 RPM, 3/8"-24 Spindle

1 × $749.58

Dynabrade 52712 2" (51 mm) Dia. Right Angle Depressed Center Wheel Grinder, .4 HP, 20,000 RPM, 3/8"-24 Spindle

1 × $749.58 -

×

Dynabrade 43510 .4 hp 6" (152 mm) Extension Die Grinder, Front Exhaust, 25,000 RPM, 1/4" Collet

1 × $730.34

Dynabrade 43510 .4 hp 6" (152 mm) Extension Die Grinder, Front Exhaust, 25,000 RPM, 1/4" Collet

1 × $730.34 -

×

Dynabrade 54907 Bearing- 19 x 7 x 6

1 × $21.89

Dynabrade 54907 Bearing- 19 x 7 x 6

1 × $21.89 -

×

Dynabrade 69453 Drop-In Motor

1 × $122.52

Dynabrade 69453 Drop-In Motor

1 × $122.52 -

×

Dynabrade 52706 4" (102 mm) Dia. Right Angle Depressed Center Wheel Grinder, .4 HP, 12,000 RPM, 3/8"-24 Spindle

1 × $844.05

Dynabrade 52706 4" (102 mm) Dia. Right Angle Depressed Center Wheel Grinder, .4 HP, 12,000 RPM, 3/8"-24 Spindle

1 × $844.05 -

×

Dynabrade 54775 4" (102 mm) Dia. Right Angle Type 27 Depressed Center Wheel Grinder, .7 HP, 13,500 RPM, 3/8"-24 Spindle

1 × $911.39

Dynabrade 54775 4" (102 mm) Dia. Right Angle Type 27 Depressed Center Wheel Grinder, .7 HP, 13,500 RPM, 3/8"-24 Spindle

1 × $911.39 -

×

Dynabrade 10844 DynaPen Reciprocating Tool Filer Kit, 14,000 SPM, 1/8" Collet

1 × $540.54

Dynabrade 10844 DynaPen Reciprocating Tool Filer Kit, 14,000 SPM, 1/8" Collet

1 × $540.54 -

×

Dynabrade 78725 5/16" x 5/8"-B53 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46

Dynabrade 78725 5/16" x 5/8"-B53 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46 -

×

Dynabrade 54917 Bearing- 47 x 25 x 12

1 × $14.04

Dynabrade 54917 Bearing- 47 x 25 x 12

1 × $14.04 -

×

Dynabrade 95600 Tune-Up Kit for .5 hp Motor

1 × $130.26

Dynabrade 95600 Tune-Up Kit for .5 hp Motor

1 × $130.26 -

×

Dynabrade 92114 1/2" W x 12" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.20

Dynabrade 92114 1/2" W x 12" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.20 -

×

Dynabrade 54777 4" (102 mm) Dia. Extended Right Angle Type 27 Depressed Center Wheel Grinder, .7 HP, 13,500 RPM, 3/8"-24 Spindle

1 × $1,059.21

Dynabrade 54777 4" (102 mm) Dia. Extended Right Angle Type 27 Depressed Center Wheel Grinder, .7 HP, 13,500 RPM, 3/8"-24 Spindle

1 × $1,059.21 -

×

Dynabrade 78165 1-1/4" Dia. x 80 Grit S/C Non-Vacuum PSA DynaCut Disc 25/pack

1 × $16.50

Dynabrade 78165 1-1/4" Dia. x 80 Grit S/C Non-Vacuum PSA DynaCut Disc 25/pack

1 × $16.50 -

×

Dynabrade 90873 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $2.14

Dynabrade 90873 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $2.14 -

×

Dynabrade 52700 3" (76 mm) Dia. 7 Degree Offset Depressed Center Wheel Grinder, .7 HP, 18,000 RPM, 3/8"-24 Spindle

1 × $607.02

Dynabrade 52700 3" (76 mm) Dia. 7 Degree Offset Depressed Center Wheel Grinder, .7 HP, 18,000 RPM, 3/8"-24 Spindle

1 × $607.02 -

×

Dynabrade 96107 Motor Tune-Up Kit

1 × $208.04

Dynabrade 96107 Motor Tune-Up Kit

1 × $208.04 -

×

Dynabrade 78007 1/2" W x 12" L Medium Non-Woven DynaBrite Belts, 10/pack

10 × $4.69

Dynabrade 78007 1/2" W x 12" L Medium Non-Woven DynaBrite Belts, 10/pack

10 × $4.69 -

×

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86

Standard Abrasives 840389, Quick Change Surface Conditioning GP Disc, A/O Very Fine, TR, BLU, 2 in, Die Q200P, 7000121644, 50/case

$1.36

Factory Stock, 7-10 Day Leadtime

The Standard Abrasive Quick Change Surface Conditioning GP Disc saves time preparing workpieces for final finishes and coatings by performing one-step prep work. This multi-purpose, resin-reinforced disc works with all types of metal and is load-resistant, making it a good choice for aluminum and other soft metals. It offers reliable results on flat surfaces and some edgework.

General Purpose (GP) Material Offers Consistent Cut and Uniform Finish

Featuring a more compact structure of non-woven fibers than Buff & Blend products, our Standard Abrasives Quick Change Surface Conditioning GP Disc is engineered to provide a consistent cut-rate while producing a uniform finish. Constructed of resin-reinforced non-woven fibers, this disc resists loading and minimizes under-cutting or gouging of the workpiece.

Standard Abrasives GP Surface Conditioning Discs are made of a tough but flexible nylon mesh that conforms to irregularities on the workpiece. A woven fabric (scrim) embedded in the nylon structure provides additional strength and durability. This helps extend the life of the disc and allows for prolonged use on ferrous materials or steel.

Recommended Applications

Choose the Standard Abrasives Surface Conditioning GP Disc for use on all metal types to perform:

- Deburring: removing large and micro burrs, edge radiusing, removing die cast flashings

- Blending: removing mill marks, tool marks and mismatches; reducing uneven edges between adjoining surfaces, reorienting surface scratch patterns, creating a smooth transition from one surface profile to another

- Cleaning: removing coatings, gaskets and surface discolorations from welds or other work surfaces

The Outstanding Performance of Surface Conditioning Material

Surface conditioning products have a non-woven construction in which fiber strands, resin, and abrasive mineral form a thick, open web or mesh. The spring-like nature of the fibers responds to the part and effectively removes unwanted burrs, soils and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity. Gaps in the web allow heat and swarf to escape, prolonging the performance of the abrasive. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, increased cut performance and extended service life.

Aluminum Oxide for Metals and Composites

The disc fibers are overlaid with aluminum oxide abrasive. Aluminum oxide discs are a good match for operators who desire an all-purpose versatility and economy. The mineral cuts fast while blending and deburring and can be used for applications on ferrous and non-ferrous metals and composites.

Quick Change Discs Boost Productivity

Quick change discs allow tool-free swap outs, maintain secure attachment at high speeds, and save operators time when switching discs between grades or applications. Easy fastening and swapping of discs enhances tool efficiency and worker productivity. The TP system features a snap-on/snap-off nylon fastening hub. TR discs have a nylon threaded male hub that easily threads onto TR or 3M Roloc type holder pads with a turn of the wrist, and the TS system has a metal hub that fastens to its holder pad with a simple twist.

Standard Abrasives Quick Change GP Discs are available with TP, TR and TS attachments in disc diameters up to 4″. Discs with 4-1/2″ to 7″ diameters have a TS 5/8-11 threaded hub that easily mounts to a TS 5/8-11 holder pad. We recommend using our discs together with a Standard Abrasives Quick Change Holder Pad to ensure optimal disc performance and to ensure that pressure is applied evenly all the way to the edge of the disc.

Quality Standard Abrasives Solutions for Industrial Applications

The Standard Abrasives brand has supplied quality abrasives to the metalworking industry for over 50 years. Customers rely on our broad offering of high performance products including coated, bonded, and non-woven abrasive lines.