-

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00 -

×

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93 -

×

Dynabrade 78127 3" Dia. Medium NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $3.91

Dynabrade 78127 3" Dia. Medium NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $3.91 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25

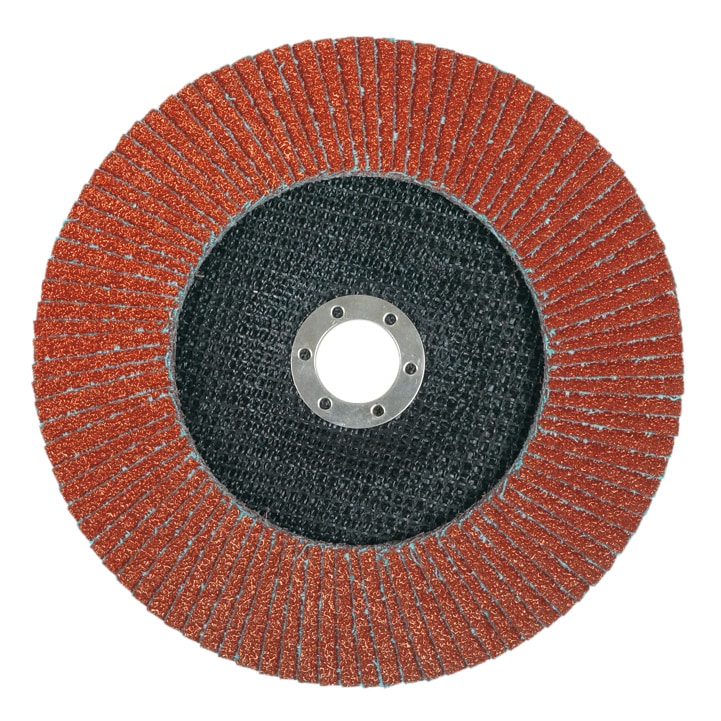

Standard Abrasives 20259, Ceramic Type 27 Flap Disc, 645026, 4-1/2 in x 7/8 in 60, 7010290408

$8.25

Discontinued, Suggested Replacement – 3M 7100178023

Constructed for rapid stock removal on welds and other similar ferrous based materials, our Standard Abrasives Ceramic Flap Disc features high-performing ceramic mineral that stays cool and reduces discoloration on stainless and high nickel alloys. The overlapping cloth flaps provide extended durability and maintain a sharp cut as the flaps wear away, leaving a smooth finish.

Aggressive Cut with a Smooth Finish

An outstanding product for metal fabrication, the Standard Abrasives™ Ceramic Flap Disc achieves fast, aggressive stock removal without compromising finish. It is ideal for a wide range of medium-high pressure applications, especially in paint prep and stainless steel fabrication where finish and gouge resistance are important. A grinding aid on the disc reduces grinding temperatures for best results and extended disc life in operations on stainless steel and steel alloys.

Outcuts and Outlasts

The overlapping layers of coated abrasive cloth flaps make this disc flexible, long lasting, sharp cutting, and a great choice for one step grinding and blending. In many instances it can replace grinding wheels and fiber discs, making it an advantageous addition to machine shops and body shops.

Compared to a regular grinding wheel, a flap disc cuts cooler, works faster, and is more user-friendly. The phenolic resin disc plate cushions the disc and reduces disc vibration, producing optimal finish and greater operator comfort. Moreover, the flexibility of the flaps also reduces vibration and produces smoother results, which means the disc is easier to control and causes less operator fatigue.

A flap disc will outlast a fiber disc while still providing an aggressive cut, so you can count on replacing it less often, which saves time and reduces consumables. It produces a smoother, more consistent finish, and won’t curl up in storage as fiber discs sometimes do. Choose one grade coarser than the fiber disc you would typically use for your application for comparable results.

Disc Workhorse Offers Great Versatility

A Standard Abrasives™ Ceramic Flap Disc provides an effective solution for many different operations. You can use it to strip paint off of metal or make quick work of rust or other contaminants. Smooth out welds, beads and burrs, knock down sharp edges and perform minor material shaping.

A flap disc may also be used for paint prep on wood, although it won’t leave the same smooth finish it achieves on metal.

Quality Solutions for Industrial Operations

Standard Abrasives™ Flap Discs were engineered with the industrial operator in mind. The Standard Abrasives brand has supplied quality abrasives to the metalworking industry for over 50 years. Customers rely on our broad offering of high performance products including coated, bonded, and non-woven abrasive lines.