-

×

3M 83759, High Performance Industrial Plastic Adhesive 4693, Light Amber, 1 Quart Can, 7000046574, 12/case

12 × $58.11

3M 83759, High Performance Industrial Plastic Adhesive 4693, Light Amber, 1 Quart Can, 7000046574, 12/case

12 × $58.11 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

25 × $1.98

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

25 × $1.98 -

×

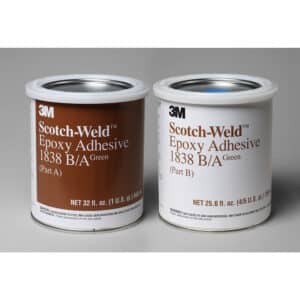

3M 20152, Scotch-Weld Epoxy Adhesive 1838, Green, Part B/A , 1 Quart Kit, 7000046340, 6/case

6 × $333.22

3M 20152, Scotch-Weld Epoxy Adhesive 1838, Green, Part B/A , 1 Quart Kit, 7000046340, 6/case

6 × $333.22 -

×

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.50

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.50 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

2 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

2 × $722.00 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71 -

×

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

2 × $33.40

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

2 × $33.40 -

×

3M 18444, HOOKIT DISC PAD HOLDER, 5 IN, 7010309484

10 × $40.96

3M 18444, HOOKIT DISC PAD HOLDER, 5 IN, 7010309484

10 × $40.96 -

×

3M 03999 Scotch-Brite Surface Conditioning Belt, SC-BS, A/O Medium, 2 in x 132 in, 7010309300

5 × $51.26

3M 03999 Scotch-Brite Surface Conditioning Belt, SC-BS, A/O Medium, 2 in x 132 in, 7010309300

5 × $51.26 -

×

3M 7494, 922, Disc Pad Holder 922, 2 in x 1/4 in Shank, 7000045864

10 × $6.97

3M 7494, 922, Disc Pad Holder 922, 2 in x 1/4 in Shank, 7000045864

10 × $6.97 -

×

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73 -

×

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33 -

×

3M 47184, Polyurethane Adhesive Sealant 550FC Fast Cure, White, 350 mL Sausage Pack, 7100197992, 12/Case (Use with 400A-2K APR, Nozzles Not Included)

12 × $10.64

3M 47184, Polyurethane Adhesive Sealant 550FC Fast Cure, White, 350 mL Sausage Pack, 7100197992, 12/Case (Use with 400A-2K APR, Nozzles Not Included)

12 × $10.64 -

×

3M 41531, Scotch-Weld Epoxy Adhesive 420, Black, Part B, 5 Gallon Drum (Pail), 7000000827

5 × $583.75

3M 41531, Scotch-Weld Epoxy Adhesive 420, Black, Part B, 5 Gallon Drum (Pail), 7000000827

5 × $583.75 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00 -

×

Dynabrade 78425 4-1/2" Dia. x 3/8" Coarse DynaBrite Surface Conditioning Disc, 25/pack

25 × $6.68

Dynabrade 78425 4-1/2" Dia. x 3/8" Coarse DynaBrite Surface Conditioning Disc, 25/pack

25 × $6.68 -

×

3M 15913, Scotch-Brite Roloc Disc High Strength, TR, 2 in X NH A Medium, 7000000710

200 × $1.72

3M 15913, Scotch-Brite Roloc Disc High Strength, TR, 2 in X NH A Medium, 7000000710

200 × $1.72 -

×

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67 -

×

3M 62605, Scotch-Weld Threadlocker TL42, Blue, 10 mL Bottle, 7100039190, 10/case

10 × $13.32

3M 62605, Scotch-Weld Threadlocker TL42, Blue, 10 mL Bottle, 7100039190, 10/case

10 × $13.32 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78 -

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00 -

×

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25 -

×

3M 14537 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 37 in x 60 in, 7100117782

1 × $532.80

3M 14537 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 37 in x 60 in, 7100117782

1 × $532.80

3M 15943 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 2 in x 18-15/16 in, 7010329255

$24.10

Factory Stock, 7-10 Day Leadtime

Among our Scotch-Brite Surface Conditioning Belts, the Scotch-Brite Surface Conditioning Low Stretch Belt falls right in the middle in terms of its durability and flexibility. Its moderate strength makes it versatile and useful in many sequences ? cutting aggressively without marring the substrate.

Designed for cleaning, finishing and light deburring

Given that the Scotch-Brite™ Surface Conditioning Low Stretch Belt balances durability with flexibility, it’s a good match for cleaning, finishing and light deburring applications. It performs best on steel and stainless steel, carbon, titanium and nickel alloys, but it may also be used on aluminum, copper, brass and soft, non-ferrous metals. We offer the Scotch-Brite™ Surface Conditioning Low Stretch Belt in many variations, so operators can find the right belt for their unique project.

Minerals, Grades and Belt Types

We engineer the Scotch-Brite™ Surface Conditioning Low Stretch Belt using aluminum oxide and silicon carbide minerals. Combinations include: aluminum oxide medium (A MED), aluminum oxide very fine (A VFN), aluminum oxide coarse (A CRS), silicon carbide medium (S MED), silicon carbide super fine (S SFN), silicon carbide very fine (S VFN). Aluminum oxide cuts softer but lasts longer than silicon carbide. It’s a good mineral for projects where a soft scratch is desirable — perhaps on softer metals or workpieces where gouging and undercutting are a primary concern.

Conversely, silicon carbide is a good match for projects where a coarser, more aggressive cut is desired. Moving along the spectrum of grades, choose a fine grade for finer finishes and medium or coarse grades for coarser finishes. Our Scotch-Brite™ Surface Conditioning Low Stretch Belt is intended for use in “low stretch” applications when a standard scrim belt is stretching on the machine or when less conformability is desired. The low-stretch belt is resistant to wear and sharp edges — rendering it useful in a variety of industries, from transportation to metal fabrication.

The belt is available in different types: file, narrow, portable, pump sleeve and wide & flat finishing. Operators should consider tools, surface area, contours and dimensions of a workpiece when choosing a belt. Narrow belts, for example, are commonly used in benchstand and backstand applications. Pump sleeves, on the other hand, are fitted around expander wheels and used for finishing large equipment that cannot be moved.

The Many Benefits of Open Web Abrasives

Nonwoven technology makes Scotch-Brite™ industrial abrasives unique. A combination of fiber strands, resin and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance and extremely long service life. Scotch-Brite products not only enhance productivity, but also increase operator. From aesthetic finishing to weld blending, deburring and more, Scotch-Brite abrasives work fast and deliver consistent results, part after part.

Scotch-Brite™ Surface Conditioning Belts

Overall, operators choose Scotch-Brite™ Surface Conditioning Belts for cleaning, finishing, blending and deburring. The non-woven material combined with abrasive grain is an ideal way to add a great finish or remove burrs while maintaining the geometry of the workpiece. Trust Scotch-Brite™ Belts to deliver fantastic finishes.