-

×

3M 40196, Cloth Spiral Band 341D, 80 X-weight 1-1/2 in x 1-1/2 in, 7100138151

100 × $0.76

3M 40196, Cloth Spiral Band 341D, 80 X-weight 1-1/2 in x 1-1/2 in, 7100138151

100 × $0.76 -

×

3M 16115, PPS Cup & Collar, Mini, 7000028417, 2 per carton

4 × $34.25

3M 16115, PPS Cup & Collar, Mini, 7000028417, 2 per carton

4 × $34.25 -

×

3M 26139, PPS Series 2.0 Adapter, Type S43, 1/4 Male, 19 Thread BSP, 7100135337

4 × $25.96

3M 26139, PPS Series 2.0 Adapter, Type S43, 1/4 Male, 19 Thread BSP, 7100135337

4 × $25.96 -

×

ACS Diamond Cloth Belt, CX1250 1/2" X 18" 125U

12 × $5.70

ACS Diamond Cloth Belt, CX1250 1/2" X 18" 125U

12 × $5.70 -

×

ACS Diamond Cloth Belt, CX1250 1" X 49" 125U

6 × $29.95

ACS Diamond Cloth Belt, CX1250 1" X 49" 125U

6 × $29.95 -

×

3M 34672, 641WY, 1/2" X 64", 100 Mesh, Diamond Cloth Belts 7100111364

1 × $37.49

3M 34672, 641WY, 1/2" X 64", 100 Mesh, Diamond Cloth Belts 7100111364

1 × $37.49

Recommended Applications

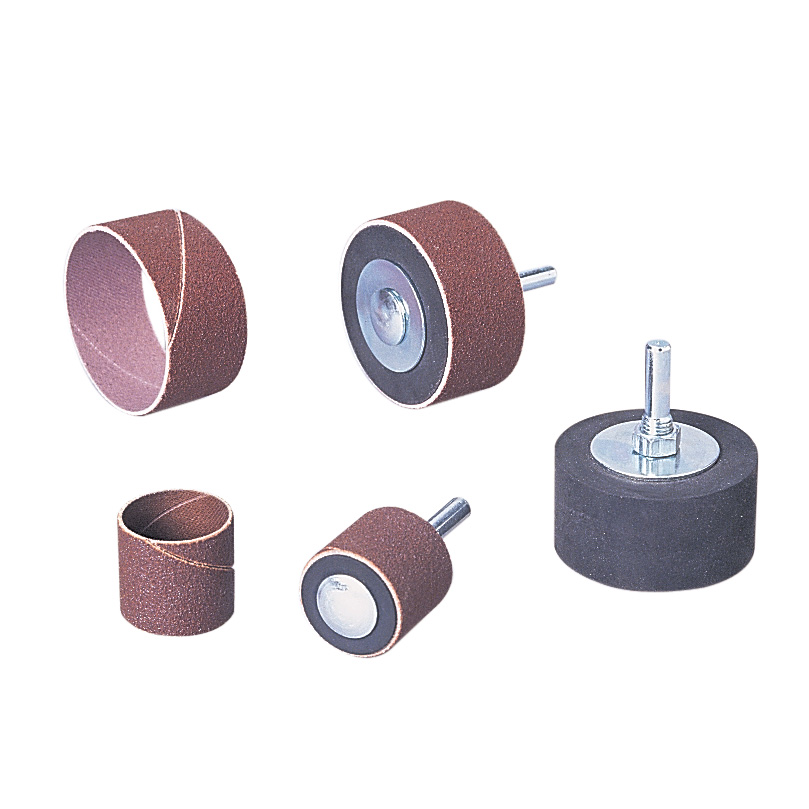

Standard Abrasives™ Aluminum Oxide Spiral Band is the best product for polishing and blending flat surfaces and contours, because its spiral shape enables it to smoothly roll over these surfaces. The circular band rotates centrifugally as you move it around the workpiece and – given its small size – the abrasive can easily fit inside hard-to-reach areas. Standard Abrasives™ Aluminum Oxide Spiral Band is great for removing parting lines, tiny imperfections and little burrs, which could otherwise be difficult to remove with a larger abrasive disc or wheel.

Special Features

The spiral construction on Standard Abrasives™ Aluminum Oxide Spiral Band eliminates shadow marks and chatter. Aluminum oxide mineral cuts sharp but is still friable, fragmenting under heat and pressure to reveal sharp cutting edges, so you get a consistent cut throughout the life of the abrasive. Available in grades 24 to 320 grit, you can choose the right grade for your project, depending how aggressive a scratch you desire. Coarser grades, like 24, are good for heavy stock removal, whereas finer grades, like 320, are good for metal finishing and polishing.

Tips for Optimal Use

Standard Abrasives™ Spiral Bands are intended for use with rubber drums. The single ply or “single thickness” abrasive fits snugly around the drum like a glove. Compared to 2- or 3-ply thicknesses, the single ply is a bit more flexible and conformable, which makes it a good match for contoured surfaces. It is important for both the drum and the abrasive to have the same nominal diameter to prevent skipping and bumping.

Rather than deflecting or skidding over the substrate, the Spiral Band stays in constant contact with the workpiece to swiftly rid the surface of little burrs. The maximum allowable RPM for spiral bands is the same as the maximum RPM of the drum, provided the drum and band have the same nominal diameter. Typically, the rubber drum attaches to portable drills, die grinders, straight shaft and angle grinders. The great news is, the drum requires no extra tools for band changes.

Removing contaminants from flat and contoured surfaces is smooth – in finish and operation.