-

×

Dynabrade 57804 3-2/3" W x 7" L Dynabug Orbital Sander, Central Vac-Ready, .24 HP, 8,000 RPM, 3/16" Orbit

1 × $550.16

Dynabrade 57804 3-2/3" W x 7" L Dynabug Orbital Sander, Central Vac-Ready, .24 HP, 8,000 RPM, 3/16" Orbit

1 × $550.16 -

×

Dynabrade 64400 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Down Exhaust

1 × $27,619.39

Dynabrade 64400 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Down Exhaust

1 × $27,619.39 -

×

3M 86803, Cubitron II Stikit Film Disc 775L, 120+, 5 in x NH, Linered w/Tab, Die 500X, 7100045865, 250 per case

250 × $0.93

3M 86803, Cubitron II Stikit Film Disc 775L, 120+, 5 in x NH, Linered w/Tab, Die 500X, 7100045865, 250 per case

250 × $0.93 -

×

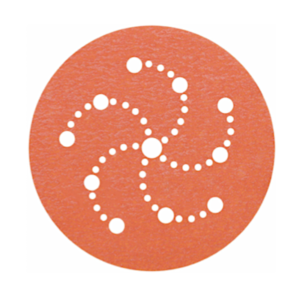

Dynabrade 91538 5" Dynacut Extreme Orange Premium Film Disc, 120 Grit, Hook & Loop, Vacuum Holes, 50/Box

1 × $35.82

Dynabrade 91538 5" Dynacut Extreme Orange Premium Film Disc, 120 Grit, Hook & Loop, Vacuum Holes, 50/Box

1 × $35.82 -

×

Dynabrade 48520 2" Dia. Right Angle Disc Sander, Rear Exhaust, .4 HP, 12,000 RPM

1 × $699.72

Dynabrade 48520 2" Dia. Right Angle Disc Sander, Rear Exhaust, .4 HP, 12,000 RPM

1 × $699.72 -

×

Dynabrade 56182 6" Dia. Non-Vacuum Disc Pad, Hook-Face Short Nap

1 × $32.53

Dynabrade 56182 6" Dia. Non-Vacuum Disc Pad, Hook-Face Short Nap

1 × $32.53 -

×

Dynabrade 53474 Direct Drive Reversible Screwdriver, .5 HP, 950 RPM, 1/4" Hex Drive

1 × $1,066.20

Dynabrade 53474 Direct Drive Reversible Screwdriver, .5 HP, 950 RPM, 1/4" Hex Drive

1 × $1,066.20 -

×

Dynabrade 13403 Dynisher Finishing Tool, Rear Exhaust, 4,500 RPM, 5/8-11" Spindle Thread

1 × $1,200.90

Dynabrade 13403 Dynisher Finishing Tool, Rear Exhaust, 4,500 RPM, 5/8-11" Spindle Thread

1 × $1,200.90 -

×

Dynabrade 53475 Direct Drive Reversible Screwdriver, .5 HP, 1,800 RPM, 1/4" Hex Drive

1 × $748.70

Dynabrade 53475 Direct Drive Reversible Screwdriver, .5 HP, 1,800 RPM, 1/4" Hex Drive

1 × $748.70 -

×

Dynabrade 52218 .5 hp 7 Degree Offset Die Grinder, Front Exhaust, Long Shank, 20,000 RPM, 1/4" Collet

1 × $508.18

Dynabrade 52218 .5 hp 7 Degree Offset Die Grinder, Front Exhaust, Long Shank, 20,000 RPM, 1/4" Collet

1 × $508.18 -

×

3M 28848, Unitized Wheel Mandrel 28848, 1-5/8 in x 1/4 in x 3/4 in x 1/4 in, 7100082547

10 × $18.31

3M 28848, Unitized Wheel Mandrel 28848, 1-5/8 in x 1/4 in x 3/4 in x 1/4 in, 7100082547

10 × $18.31 -

×

Dynabrade 96358 Pliers

1 × $58.81

Dynabrade 96358 Pliers

1 × $58.81 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52 -

×

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $409.44

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $409.44 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76 -

×

Dynabrade 57851 3-2/3" W x 7" L Non-Vacuum Dynabug Disc Pad, Hook-Face, Short Nap

1 × $33.01

Dynabrade 57851 3-2/3" W x 7" L Non-Vacuum Dynabug Disc Pad, Hook-Face, Short Nap

1 × $33.01 -

×

Dynabrade 96241 Bearing Press Tool

1 × $61.96

Dynabrade 96241 Bearing Press Tool

1 × $61.96 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $431.21

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $431.21 -

×

Dynabrade 50010 Collet, 3/8"-24 Female Thread, 1/4" Capacity, 3-Piece Collet

1 × $77.83

Dynabrade 50010 Collet, 3/8"-24 Female Thread, 1/4" Capacity, 3-Piece Collet

1 × $77.83 -

×

Dynabrade 98273 - 1/2" Female Coupler with 1/2" Male Plug Assembly

1 × $84.53

Dynabrade 98273 - 1/2" Female Coupler with 1/2" Male Plug Assembly

1 × $84.53 -

×

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

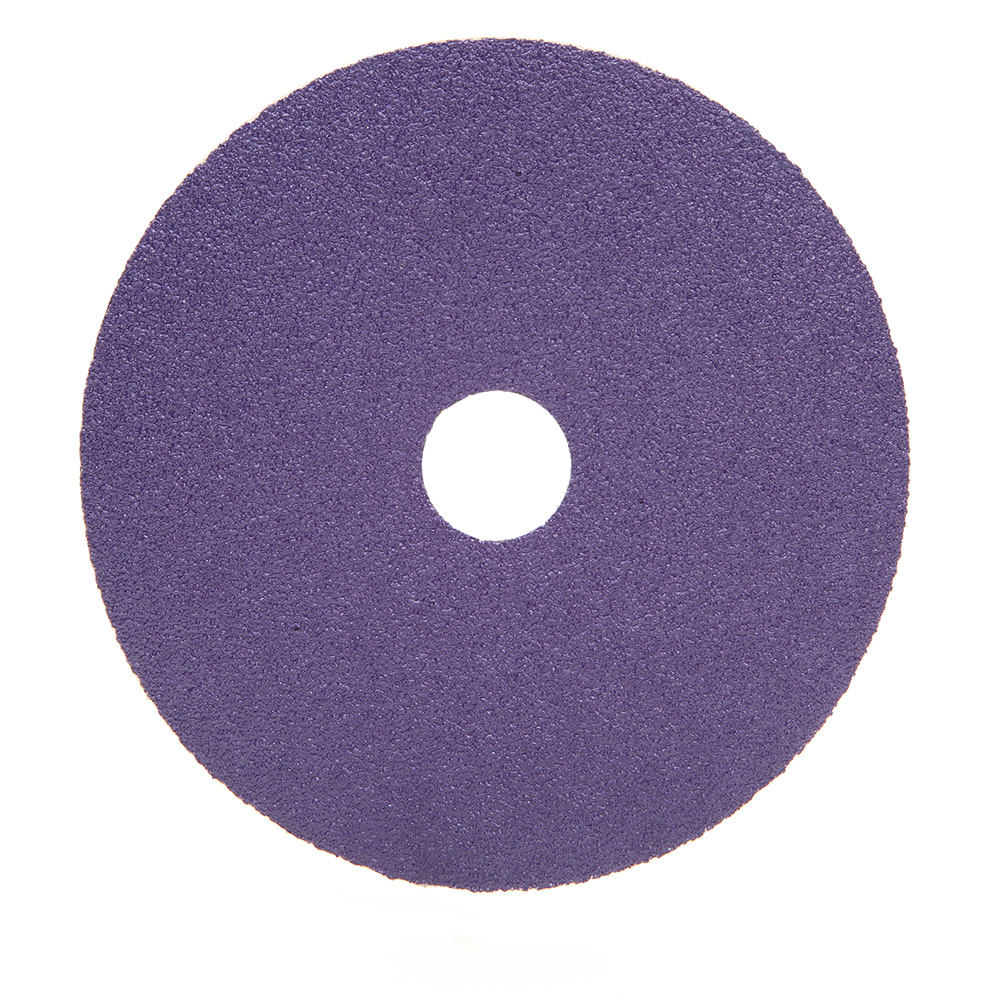

3M 33416, Cubitron II Abrasive Fibre Disc, 5 in X 7/8 in (125mm X 22mm), 80+, 7100033182, 5 discs per carton

$33.09

Factory Stock, 7-10 Day Leadtime, Priced Per Carton

3M’s Cubitron II Abrasive Fibre Discs is built for faster cutting of welds as well as grinding, weld blending, deburring and other tough metal finishing jobs. 3M Precision Shaped Grain – a tough, sharp ceramic abrasive – is resin-bonded to a stiff fiber backing. This disc lasts significantly longer than conventional ceramic grain discs, delivering a lower cost per grind with fewer disc changes.