-

×

Dynabrade 94996 Belt Strap

1 × $4.78

Dynabrade 94996 Belt Strap

1 × $4.78 -

×

Dynabrade 96542 Motor Tune-Up Kit

1 × $217.61

Dynabrade 96542 Motor Tune-Up Kit

1 × $217.61 -

×

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $963.87

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $963.87 -

×

Dynabrade 61463 Raptor Vac Air Powered Portable Vacuum System, 7.9 Gallon

1 × $12,871.76

Dynabrade 61463 Raptor Vac Air Powered Portable Vacuum System, 7.9 Gallon

1 × $12,871.76 -

×

Dynabrade 900 8" Dia. Two-Hand Gear-Driven Sander, Non-Vacuum, .25 HP, 800 RPM, 3/16" Orbit, PSA

1 × $585.32

Dynabrade 900 8" Dia. Two-Hand Gear-Driven Sander, Non-Vacuum, .25 HP, 800 RPM, 3/16" Orbit, PSA

1 × $585.32 -

×

Dynabrade 50125 3" Dia. Disc Backup Pad, 1/4"-20 Thread, Hook 'N Loop

1 × $20.51

Dynabrade 50125 3" Dia. Disc Backup Pad, 1/4"-20 Thread, Hook 'N Loop

1 × $20.51 -

×

Dynabrade 95956 Cuff

1 × $39.46

Dynabrade 95956 Cuff

1 × $39.46 -

×

Dynabrade 54783 3" (76 mm) Dia. Right Angle Type 27 Depressed Center Wheel Grinder, Steel Housing, .7 HP, 18,000 RPM, 3/8"-24 Spindle

1 × $1,024.22

Dynabrade 54783 3" (76 mm) Dia. Right Angle Type 27 Depressed Center Wheel Grinder, Steel Housing, .7 HP, 18,000 RPM, 3/8"-24 Spindle

1 × $1,024.22 -

×

Dynabrade 52861 .4 hp Straight-Line Pencil Grinder, Rear Exhaust, 25,000 RPM, 1/8" Collet

1 × $555.41

Dynabrade 52861 .4 hp Straight-Line Pencil Grinder, Rear Exhaust, 25,000 RPM, 1/8" Collet

1 × $555.41 -

×

Dynabrade 95216 Pin

1 × $1.93

Dynabrade 95216 Pin

1 × $1.93 -

×

Dynabrade 68101 Coolant Filtration System, 230 V (AC), 1 Phase, 50 Hz

1 × $3,859.84

Dynabrade 68101 Coolant Filtration System, 230 V (AC), 1 Phase, 50 Hz

1 × $3,859.84 -

×

Dynabrade 78860 Crimped Wire Radial Wheel Brush 2" Dia. x .006 x 7/16" Steel

1 × $16.96

Dynabrade 78860 Crimped Wire Radial Wheel Brush 2" Dia. x .006 x 7/16" Steel

1 × $16.96 -

×

Dynabrade 01788 Screw

1 × $1.93

Dynabrade 01788 Screw

1 × $1.93 -

×

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $508.22

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $508.22 -

×

Dynabrade 43516 .4 hp 6" (152 mm) Dia. Extension Die Grinder, Rear Exhaust, 25,000 RPM, 1/4" Collet

1 × $738.21

Dynabrade 43516 .4 hp 6" (152 mm) Dia. Extension Die Grinder, Rear Exhaust, 25,000 RPM, 1/4" Collet

1 × $738.21 -

×

Dynabrade 56158 6" Dia. Non-Vacuum Disc Pad, Hook-Face, Short Nap

1 × $39.13

Dynabrade 56158 6" Dia. Non-Vacuum Disc Pad, Hook-Face, Short Nap

1 × $39.13 -

×

Dynabrade 96045 Motor Tune-Up Kit

1 × $163.63

Dynabrade 96045 Motor Tune-Up Kit

1 × $163.63 -

×

Dynabrade 49420 .4 hp Angle-Head Die Grinder, Rear Exhaust, 3,200 RPM, 1/4" Collet

1 × $1,156.29

Dynabrade 49420 .4 hp Angle-Head Die Grinder, Rear Exhaust, 3,200 RPM, 1/4" Collet

1 × $1,156.29 -

×

Dynabrade 56106 5" Dia. Non-Vacuum Disc Pad, Vinyl-Face

1 × $23.43

Dynabrade 56106 5" Dia. Non-Vacuum Disc Pad, Vinyl-Face

1 × $23.43 -

×

Dynabrade 53207 Vacuum Assembly

1 × $105.34

Dynabrade 53207 Vacuum Assembly

1 × $105.34 -

×

3M Super Abrasives Roloc Disc, 2" Type-R, Medium AO High Strength, Box of 50

1 × $77.50

3M Super Abrasives Roloc Disc, 2" Type-R, Medium AO High Strength, Box of 50

1 × $77.50

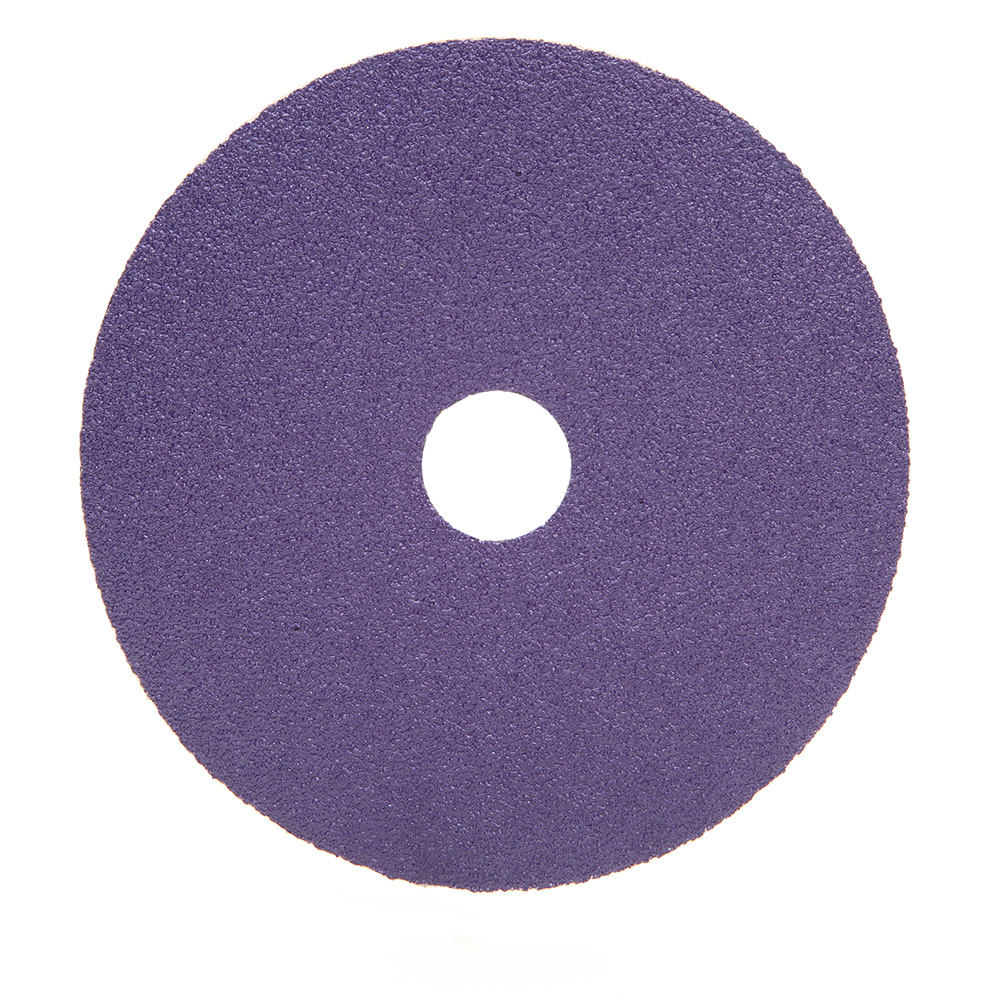

3M 33416, Cubitron II Abrasive Fibre Disc, 5 in X 7/8 in (125mm X 22mm), 80+, 7100033182, 5 discs per carton

$33.09

Factory Stock, 7-10 Day Leadtime, Priced Per Carton

3M’s Cubitron II Abrasive Fibre Discs is built for faster cutting of welds as well as grinding, weld blending, deburring and other tough metal finishing jobs. 3M Precision Shaped Grain – a tough, sharp ceramic abrasive – is resin-bonded to a stiff fiber backing. This disc lasts significantly longer than conventional ceramic grain discs, delivering a lower cost per grind with fewer disc changes.