3M 28878, Finesse-it Advanced Foam Buffing Pad, 28878, 3-1/4 in, Gray, 10/Bag, 50 ea/Case, 7100085948

This item has been Discontinued. Please see 3M suggested replacement item 7100322115.

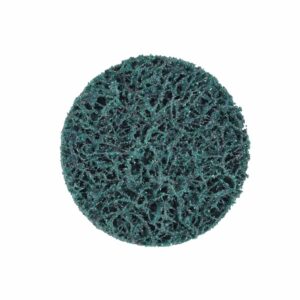

3M Finesse-it Advanced Foam Buffing Pads are available with a convolute or flat shape for use with our specially developed 3M Finesse-it polishes to achieve satin, semi-gloss or high gloss finishes on Advanced coatings in automotive, marine, aerospace and wood.

High Quality Finishing

The 3M™ Finesse-it™ Advanced Foam Buffing Pads remove the abrasive sand scratches that were created to remove small defects in automotive clear coats. You can also use this buffing pad in the 3M™ Finesse-it&trade Paint Repair System for AOEM paint and clear coats whenever the finest finish is required. The Advanced foam reduces heat buildup during buffing and helps eliminates swirl marks. These pads are manufactured with our hook and loop attachment system for quick pad attachment and removal and to hold the pad securely in place during use. These Advanced buffing pads conveniently and firmly attach to a hook-and-loop backup disc pad (sold separately) on rotary or random orbital tools, can be removed cleanly and easily, and can be re-used again and again for the life of the pad. Finish results are dependent on the combination of coating type, polish, and tools used.

Heat Resistant

We developed our line of foam pads to address the unique chemical composition of evolving paint and clear coat technologies. Foam pads are generally less aggressive and produce a finer finish than wool pads. They normally operate at higher RPMs than wool pads also, relying on a combination of cutting and speed to remove fine scratches, swirl marks, and surface marring. Foam pads range in abrasive levels determined by its softness and the cell size of the holes; the larger the hole, the more aggressive the pad. “Closed cell” pads are the least aggressive type. Foam buffing pads are used in conjunction with polishes and are recommended for use with random orbital tools.

Finesse-it™ Buffing System

Our line of 3M™ Finesse-it™ products are specially engineered abrasives, compounds, polishes, and buffing pads to be used on OEM and fully cured refinish coatings to remove defects, sand scratches, or swirl marks on a variety of painted surfaces. Finesse-it™ products are an integral part of our recommended buffing system for repairing surface defects to clear coats, lacquered wood, solid surfaces, gelcoat, powder coat, industrial paint, acrylic, and glass.

Dynabrade 11395 Guide Wheel

Dynabrade 11395 Guide Wheel  Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each  Dynabrade 78424 4-1/2" Dia. x 3/8" Medium DynaBrite Surface Conditioning Disc, 25/pack

Dynabrade 78424 4-1/2" Dia. x 3/8" Medium DynaBrite Surface Conditioning Disc, 25/pack