-

×

Dynabrade 55209 Governor Spring- 6K RPM

1 × $10.11

Dynabrade 55209 Governor Spring- 6K RPM

1 × $10.11 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $688.35

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $688.35 -

×

Dynabrade 54777 4" (102 mm) Dia. Extended Right Angle Type 27 Depressed Center Wheel Grinder, .7 HP, 13,500 RPM, 3/8"-24 Spindle

1 × $1,059.21

Dynabrade 54777 4" (102 mm) Dia. Extended Right Angle Type 27 Depressed Center Wheel Grinder, .7 HP, 13,500 RPM, 3/8"-24 Spindle

1 × $1,059.21 -

×

Dynabrade 55245 Silencer

1 × $30.81

Dynabrade 55245 Silencer

1 × $30.81 -

×

Dynabrade 95990 Wet Tank Assembly

2 × $137.01

Dynabrade 95990 Wet Tank Assembly

2 × $137.01 -

×

Dynabrade 98265 3/8" Female Coupler with 3/8" Male Plug Assembly

1 × $86.59

Dynabrade 98265 3/8" Female Coupler with 3/8" Male Plug Assembly

1 × $86.59 -

×

Dynabrade 55637 Throttle Handle Sub Assembly

1 × $191.20

Dynabrade 55637 Throttle Handle Sub Assembly

1 × $191.20 -

×

Dynabrade 07140 Guard Assembly

1 × $142.60

Dynabrade 07140 Guard Assembly

1 × $142.60 -

×

Dynabrade 58359 Bearing Plate

1 × $36.49

Dynabrade 58359 Bearing Plate

1 × $36.49 -

×

Dynabrade 54732 3" (76 mm) Dia. Extended Right Angle Type 1 Cut-Off Tool, Rear Exhaust, .7 HP, 18,000 RPM, 3/8"-24 Spindle

1 × $1,025.97

Dynabrade 54732 3" (76 mm) Dia. Extended Right Angle Type 1 Cut-Off Tool, Rear Exhaust, .7 HP, 18,000 RPM, 3/8"-24 Spindle

1 × $1,025.97 -

×

Dynabrade 51520 Industrial Quality Wet Polisher, .7 HP, 500-3,600 RPM, 5/8"-11 Spindle Thread

1 × $1,156.29

Dynabrade 51520 Industrial Quality Wet Polisher, .7 HP, 500-3,600 RPM, 5/8"-11 Spindle Thread

1 × $1,156.29 -

×

Dynabrade 10966 Barb, Swivel

1 × $36.49

Dynabrade 10966 Barb, Swivel

1 × $36.49 -

×

Dynabrade 51076 Spindle Housing

1 × $182.96

Dynabrade 51076 Spindle Housing

1 × $182.96 -

×

Dynabrade 52962 Carrier Adapter

1 × $139.38

Dynabrade 52962 Carrier Adapter

1 × $139.38 -

×

Dynabrade 21498 ND3621, 6" Shroud, DE

1 × $28.30

Dynabrade 21498 ND3621, 6" Shroud, DE

1 × $28.30 -

×

Dynabrade 20021 Flexible Collet Insert

1 × $6.09

Dynabrade 20021 Flexible Collet Insert

1 × $6.09 -

×

Dynabrade 64000 SuperFinisher, 115 Volts (AC), 1 Phase, 60 Hz

1 × $18,455.12

Dynabrade 64000 SuperFinisher, 115 Volts (AC), 1 Phase, 60 Hz

1 × $18,455.12 -

×

Dynabrade 92822 3-1/4" Dia. x 3" W Standard Dynacushion Pneumatic Wheel

1 × $220.33

Dynabrade 92822 3-1/4" Dia. x 3" W Standard Dynacushion Pneumatic Wheel

1 × $220.33 -

×

Dynabrade 69520 Motor Ass'y- Mini-Dynorbital

1 × $254.54

Dynabrade 69520 Motor Ass'y- Mini-Dynorbital

1 × $254.54 -

×

Dynabrade 18588 Exhaust Gasket

1 × $6.16

Dynabrade 18588 Exhaust Gasket

1 × $6.16 -

×

Dynabrade 51367 Rear Bearing Plate

1 × $38.94

Dynabrade 51367 Rear Bearing Plate

1 × $38.94 -

×

Dynabrade 02649 Bearing

1 × $15.87

Dynabrade 02649 Bearing

1 × $15.87 -

×

Dynabrade 64987 Replacement Pre-Filter Blanket

1 × $53.58

Dynabrade 64987 Replacement Pre-Filter Blanket

1 × $53.58 -

×

Dynabrade 96328 O-Ring

1 × $1.93

Dynabrade 96328 O-Ring

1 × $1.93 -

×

Dynabrade 56586 Vacuum Plug

1 × $13.46

Dynabrade 56586 Vacuum Plug

1 × $13.46 -

×

Dynabrade 69312 Housing Replacement for Model No. 69020

1 × $82.72

Dynabrade 69312 Housing Replacement for Model No. 69020

1 × $82.72 -

×

Dynabrade 91240 8" Dia. x 150 Grit A/O Non-Vacuum PSA DynaCut Disc, 25/Box

25 × $2.75

Dynabrade 91240 8" Dia. x 150 Grit A/O Non-Vacuum PSA DynaCut Disc, 25/Box

25 × $2.75 -

×

Dynabrade 92918 - 2" (51 mm) Dia. x 2" (51 mm) W Slotted Wheel

1 × $105.57

Dynabrade 92918 - 2" (51 mm) Dia. x 2" (51 mm) W Slotted Wheel

1 × $105.57 -

×

Dynabrade 95457 Wrench Assembly

2 × $155.60

Dynabrade 95457 Wrench Assembly

2 × $155.60 -

×

Dynabrade 92849 - 3" (76 mm) Dia. x 2-1/4" (57 mm) W Heavy Duty Dynacushion Pneumatic Wheel

1 × $162.10

Dynabrade 92849 - 3" (76 mm) Dia. x 2-1/4" (57 mm) W Heavy Duty Dynacushion Pneumatic Wheel

1 × $162.10 -

×

Dynabrade 56294 - 4-1/4" (108 mm) W x 4-1/2" (114 mm) L Vacuum Dynabug "Model T" Disc Pad, Hook-Face, Short Nap

1 × $25.78

Dynabrade 56294 - 4-1/4" (108 mm) W x 4-1/2" (114 mm) L Vacuum Dynabug "Model T" Disc Pad, Hook-Face, Short Nap

1 × $25.78 -

×

Dynabrade 78661 1/2" Dia. x 1" W x 1/8" Center Hole, Tapered Cartridge Rolls, A/O, 80 Grit, 100/pack

100 × $1.13

Dynabrade 78661 1/2" Dia. x 1" W x 1/8" Center Hole, Tapered Cartridge Rolls, A/O, 80 Grit, 100/pack

100 × $1.13 -

×

Dynabrade 53694 Planetary Cover

1 × $197.41

Dynabrade 53694 Planetary Cover

1 × $197.41 -

×

Dynabrade 56664 Housing Assy for Model 59108; 12,000 RPM

1 × $95.66

Dynabrade 56664 Housing Assy for Model 59108; 12,000 RPM

1 × $95.66 -

×

Dynabrade 92203 1-1/2" W x 30" L 120 Grit A/Z DynaCut Belt, 50/pack

50 × $5.32

Dynabrade 92203 1-1/2" W x 30" L 120 Grit A/Z DynaCut Belt, 50/pack

50 × $5.32 -

×

Dynabrade 76000 Dynabrade Buffing Kit

1 × $70.66

Dynabrade 76000 Dynabrade Buffing Kit

1 × $70.66 -

×

Dynabrade 50541 Governor Valve

1 × $94.05

Dynabrade 50541 Governor Valve

1 × $94.05 -

×

Dynabrade 57987 Base Plate Assembly

1 × $81.06

Dynabrade 57987 Base Plate Assembly

1 × $81.06 -

×

Dynabrade 01894 Drop-In Motor

1 × $589.02

Dynabrade 01894 Drop-In Motor

1 × $589.02 -

×

Dynabrade 13519 Dynastraight 6" (152 mm) Extension Finishing Tool, 1 HP, Rear Exhaust, 6,000 RPM, 5/8"-11 Arbor

1 × $1,219.27

Dynabrade 13519 Dynastraight 6" (152 mm) Extension Finishing Tool, 1 HP, Rear Exhaust, 6,000 RPM, 5/8"-11 Arbor

1 × $1,219.27 -

×

Dynabrade 50777 Rotor

1 × $117.28

Dynabrade 50777 Rotor

1 × $117.28 -

×

Dynabrade 18842 Front End Plate

1 × $39.02

Dynabrade 18842 Front End Plate

1 × $39.02 -

×

Dynabrade 51972 Cover, Router, 1 hp, F.E.

1 × $50.25

Dynabrade 51972 Cover, Router, 1 hp, F.E.

1 × $50.25 -

×

Dynabrade 18807 Spring

1 × $1.75

Dynabrade 18807 Spring

1 × $1.75 -

×

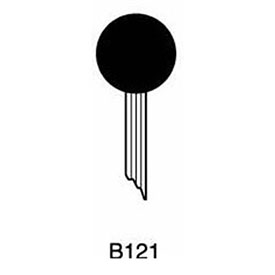

Dynabrade 78749 1/2" x 1/2"-B121 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $2.34

Dynabrade 78749 1/2" x 1/2"-B121 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $2.34 -

×

Dynabrade 51339 Housing Ass'y for 51333

1 × $131.31

Dynabrade 51339 Housing Ass'y for 51333

1 × $131.31 -

×

Dynabrade 48521 2" Dia. Right Angle Disc Sander, Rear Exhaust, .4 HP, 15,000 RPM

1 × $699.72

Dynabrade 48521 2" Dia. Right Angle Disc Sander, Rear Exhaust, .4 HP, 15,000 RPM

1 × $699.72 -

×

Dynabrade 95446 Washer

1 × $5.12

Dynabrade 95446 Washer

1 × $5.12 -

×

Dynabrade 78304 1-1/2" Dia. x 1" W x 1/4" Shank, 60 Grit, A/O DynaCut Flap Wheel, 10/pack

10 × $5.28

Dynabrade 78304 1-1/2" Dia. x 1" W x 1/4" Shank, 60 Grit, A/O DynaCut Flap Wheel, 10/pack

10 × $5.28 -

×

Dynabrade 53216 Pipe Adapter

1 × $74.28

Dynabrade 53216 Pipe Adapter

1 × $74.28 -

×

Dynabrade 18743 Pin (2)

1 × $2.03

Dynabrade 18743 Pin (2)

1 × $2.03 -

×

Dynabrade 21870 ND8700, Paper Clamp Pin

1 × $1.25

Dynabrade 21870 ND8700, Paper Clamp Pin

1 × $1.25 -

×

Dynabrade 96240 Bearing Press Tool

1 × $61.96

Dynabrade 96240 Bearing Press Tool

1 × $61.96

3M 28864, Finesse-it Knit II Buffing Pad, 28864, 7 in, 1/2 in Pile Height, 10 ea/Case, 7100081911

$12.94

Factory Stock, 7-10 Day Leadtime

3M Finesse-it Knit II Buffing Pads are manufactured with wool fibers knit into a polyester fabric backing to apply the Finesse-it Finishing Material or Finesse-it Final Finish. These are ideal for buffing automotive OEM, marine, and aerospace coatings. These pads are trimmed to specified pile height, making ideal for compounding and polishing in hard to access areas.