-

×

Dynabrade 48036 1-1/4" Mini Orbital Sander, 8K RPM, .4Hp Right Angle, Front Exhaust

1 × $957.00

Dynabrade 48036 1-1/4" Mini Orbital Sander, 8K RPM, .4Hp Right Angle, Front Exhaust

1 × $957.00 -

×

Dynabrade 02572 Spring

1 × $24.36

Dynabrade 02572 Spring

1 × $24.36 -

×

Dynabrade 93662 5" Dia. x 3/4" Center Hole, 40/50 Grit Gulleted/Slotted Diamond Cut-Off Wheel

1 × $213.21

Dynabrade 93662 5" Dia. x 3/4" Center Hole, 40/50 Grit Gulleted/Slotted Diamond Cut-Off Wheel

1 × $213.21 -

×

Dynabrade 67045 - 2" X 3/4" Contact Wheel Assy

1 × $151.03

Dynabrade 67045 - 2" X 3/4" Contact Wheel Assy

1 × $151.03 -

×

Dynabrade 33141 NDDP1028, Piston

1 × $47.95

Dynabrade 33141 NDDP1028, Piston

1 × $47.95 -

×

Dynabrade 95890 Pin

1 × $19.54

Dynabrade 95890 Pin

1 × $19.54 -

×

Dynabrade X62ESD 6" Dia. Central-Vacuum Dynorbital Extreme Random Orbital Sander for ESD

1 × $286.00

Dynabrade X62ESD 6" Dia. Central-Vacuum Dynorbital Extreme Random Orbital Sander for ESD

1 × $286.00 -

×

Dynabrade 60206 - 3,000 lb. Jack with 1/2" Vi-Sorb Pad

1 × $205.91

Dynabrade 60206 - 3,000 lb. Jack with 1/2" Vi-Sorb Pad

1 × $205.91 -

×

Dynabrade 60213 - 15,000 lb. Jack with 3/4" Vi-Sorb Pad

1 × $310.50

Dynabrade 60213 - 15,000 lb. Jack with 3/4" Vi-Sorb Pad

1 × $310.50 -

×

Dynabrade 78370 6" Dia. x 1" W x 1" Center Hole, 8SFine S/C DynaBrite Deburring Type-R Convolute Wheel, 2/box

2 × $165.92

Dynabrade 78370 6" Dia. x 1" W x 1" Center Hole, 8SFine S/C DynaBrite Deburring Type-R Convolute Wheel, 2/box

2 × $165.92 -

×

Dynabrade 13039 Sleeve

1 × $28.89

Dynabrade 13039 Sleeve

1 × $28.89 -

×

Dynabrade 02444 2 hp Housing Assembly for 53251

1 × $440.22

Dynabrade 02444 2 hp Housing Assembly for 53251

1 × $440.22 -

×

Dynabrade 57404BKV 2-3/4" W x 8" L Dynaline Sander, Vacuum

1 × $5,561.00

Dynabrade 57404BKV 2-3/4" W x 8" L Dynaline Sander, Vacuum

1 × $5,561.00 -

×

Dynabrade Nitro Series 50209 Polisher Kit, w/ RB3 Buffer

1 × $379.00

Dynabrade Nitro Series 50209 Polisher Kit, w/ RB3 Buffer

1 × $379.00 -

×

Dynabrade 53234 7" Dia. Type 27 Vertical Depressed Center Wheel Grinder, 2 HP, 7,200 RPM, 5/8"-11 Spindle

1 × $1,559.00

Dynabrade 53234 7" Dia. Type 27 Vertical Depressed Center Wheel Grinder, 2 HP, 7,200 RPM, 5/8"-11 Spindle

1 × $1,559.00 -

×

Dynabrade 78870 Concave Brush 2" Dia. x .014 x 1/2" Steel

1 × $16.96

Dynabrade 78870 Concave Brush 2" Dia. x .014 x 1/2" Steel

1 × $16.96 -

×

Dynabrade 69474 - 5" (127 mm) Dia. Dynorbital Silver Supreme Drop-In Motor 10 Pack

1 × $1,248.97

Dynabrade 69474 - 5" (127 mm) Dia. Dynorbital Silver Supreme Drop-In Motor 10 Pack

1 × $1,248.97

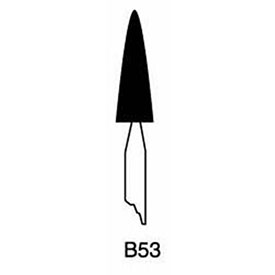

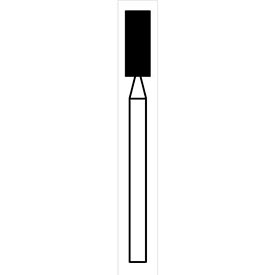

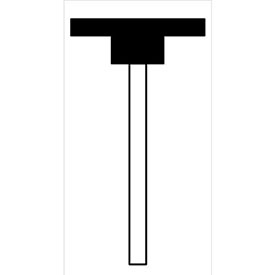

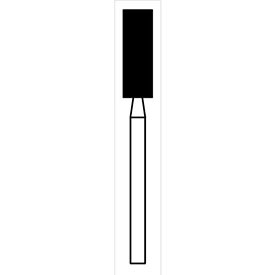

Standard Abrasives 877067, Unitized Mounted Point, 732 W189 x 1/4 in, 3M 7000047015

$13.91

Factory Stock, 7-10 Day Leadtime

Our Standard Abrasives Unitized Mounted Point lightly deburrs, blends and finishes metal and plastic parts. Choose from many different shapes and sizes to match specific small parts with hard-to-reach areas. Unitized mounted points deburr and finish without altering the shape of the workpiece, and self-dress to continually expose fresh mineral during use for efficient operations.