-

×

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00 -

×

3M 91461, Scotch Packaging Tape 3450S-RD-36GC, 1.88 in x 38.2 yd (48 mm x 35 m), 7100260773

72 × $4.82

3M 91461, Scotch Packaging Tape 3450S-RD-36GC, 1.88 in x 38.2 yd (48 mm x 35 m), 7100260773

72 × $4.82 -

×

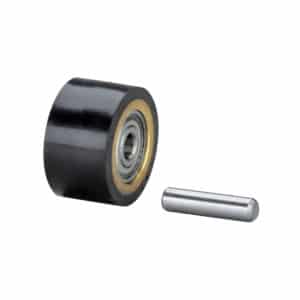

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $36.60

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $36.60 -

×

3M 92210, Scotch Shipping Packaging Tape 3950S-6, 1.88 in x 38.2 yd (48 mm x 35 m), 7100242420

6 × $26.35

3M 92210, Scotch Shipping Packaging Tape 3950S-6, 1.88 in x 38.2 yd (48 mm x 35 m), 7100242420

6 × $26.35 -

×

3M 85640, Scotch Shipping Packaging Tape 195, 1.88 in x 22.2 yd (48 mm x 20.3 m), 7100233595

36 × $2.96

3M 85640, Scotch Shipping Packaging Tape 195, 1.88 in x 22.2 yd (48 mm x 20.3 m), 7100233595

36 × $2.96 -

×

Dynabrade 69481 5" Extreme Drop-in Motor, 3/32" Orbit

1 × $164.91

Dynabrade 69481 5" Extreme Drop-in Motor, 3/32" Orbit

1 × $164.91 -

×

Dynabrade 79145 1/4" W x 24" L 60 Grit DynaCut Premium Ceramic Belt, 50/pack

50 × $3.19

Dynabrade 79145 1/4" W x 24" L 60 Grit DynaCut Premium Ceramic Belt, 50/pack

50 × $3.19 -

×

3M 85162, Scotch Packaging Tape 3950S-RD-6WC, 1.88 in x 38.2 yd (48 mm x 35 m), 7100247466

6 × $6.79

3M 85162, Scotch Packaging Tape 3950S-RD-6WC, 1.88 in x 38.2 yd (48 mm x 35 m), 7100247466

6 × $6.79 -

×

3M 15095, Scotch Heavy Duty Masking Tape 2020+-48TP6, 1.88 in x 60.1 yd (48mm x55m), 6 rolls/pack, 7100191056

4 × $22.27

3M 15095, Scotch Heavy Duty Masking Tape 2020+-48TP6, 1.88 in x 60.1 yd (48mm x55m), 6 rolls/pack, 7100191056

4 × $22.27 -

×

Dynabrade 59339 Vacuum Cuff, 1", w/Groove

1 × $13.53

Dynabrade 59339 Vacuum Cuff, 1", w/Groove

1 × $13.53 -

×

3M 93947, Scotch Stucco Tape 3260-A, 1.88 in x 60 yd (48 mm x 54.8 m), Stucco Tape, 7010384961

24 × $6.60

3M 93947, Scotch Stucco Tape 3260-A, 1.88 in x 60 yd (48 mm x 54.8 m), Stucco Tape, 7010384961

24 × $6.60 -

×

Dynabrade 92115 1/2" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.29

Dynabrade 92115 1/2" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.29 -

×

Dynabrade 92102 3" W x 10-11/16" L 80 Grit A/Z DynaCut Belt, 10/pack

10 × $4.16

Dynabrade 92102 3" W x 10-11/16" L 80 Grit A/Z DynaCut Belt, 10/pack

10 × $4.16 -

×

Dynabrade 31968 Conductive Y Adapter

1 × $49.41

Dynabrade 31968 Conductive Y Adapter

1 × $49.41 -

×

3M 53602, Paper Masking Tape 2214, Tan, 48 mm x 50 m, 5.4 mil, 24 Rolls/Case, 7100245636

24 × $8.18

3M 53602, Paper Masking Tape 2214, Tan, 48 mm x 50 m, 5.4 mil, 24 Rolls/Case, 7100245636

24 × $8.18 -

×

Dynabrade 64674 Filter Cartridge

1 × $75.74

Dynabrade 64674 Filter Cartridge

1 × $75.74 -

×

Dynabrade 31949 Vacuum Hose Ass'y, 3/4" Vac, 5/16" Air Hose

2 × $203.57

Dynabrade 31949 Vacuum Hose Ass'y, 3/4" Vac, 5/16" Air Hose

2 × $203.57 -

×

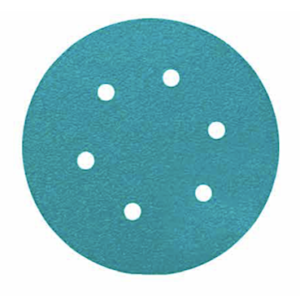

Dynabrade 82495 6" Dia. x 400 Grit A/O Vacuum PSA Filmbac DynaCut Disc, 100/Pack

100 × $1.47

Dynabrade 82495 6" Dia. x 400 Grit A/O Vacuum PSA Filmbac DynaCut Disc, 100/Pack

100 × $1.47 -

×

Dynabrade 78538 3/4"Dia. 2-Set, 3-48 Female Center Thread, 80 Grit, Dynacut A/O Overlap Slotted Disc, 100/pack

100 × $1.10

Dynabrade 78538 3/4"Dia. 2-Set, 3-48 Female Center Thread, 80 Grit, Dynacut A/O Overlap Slotted Disc, 100/pack

100 × $1.10 -

×

Dynabrade 07107 Vane Set (5pk)

1 × $33.82

Dynabrade 07107 Vane Set (5pk)

1 × $33.82

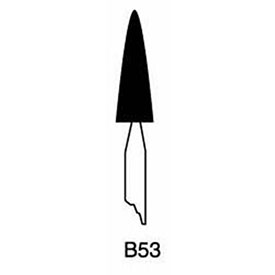

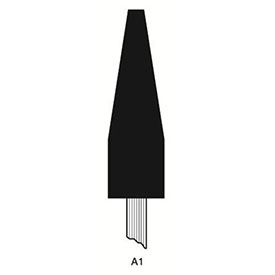

Standard Abrasives 877059, Unitized Mounted Point, 732 A3 x 1/4 in, 3M 7010310345

$29.83

Factory Stock, 7-10 Day Leadtime

Our Standard Abrasives Unitized Mounted Point lightly deburrs, blends and finishes metal and plastic parts. Choose from many different shapes and sizes to match specific small parts with hard-to-reach areas. Unitized mounted points deburr and finish without altering the shape of the workpiece, and self-dress to continually expose fresh mineral during use for efficient operations.