-

×

Dynabrade 82432 5" Dia. x 180 Grit A/O Hook Non-Vacuum Film-Backed DynaCut Disc, 100/Box

1 × $74.24

Dynabrade 82432 5" Dia. x 180 Grit A/O Hook Non-Vacuum Film-Backed DynaCut Disc, 100/Box

1 × $74.24 -

×

Dynabrade 52280 .55 hp Right Angle Die Grinder, Rear Exhaust, 15,00 RPM, 1/4" Collet

2 × $517.00

Dynabrade 52280 .55 hp Right Angle Die Grinder, Rear Exhaust, 15,00 RPM, 1/4" Collet

2 × $517.00 -

×

Dynabrade 95816 Air Line

1 × $67.05

Dynabrade 95816 Air Line

1 × $67.05 -

×

Dynabrade 57052 Bearing Assembly

1 × $72.91

Dynabrade 57052 Bearing Assembly

1 × $72.91 -

×

Dynabrade 78757 1" x 2"-W222 Dynacut Z/A Mounted Point, 5/pack

5 × $8.95

Dynabrade 78757 1" x 2"-W222 Dynacut Z/A Mounted Point, 5/pack

5 × $8.95 -

×

Dynabrade 54944 Throttle Ball Seat

1 × $29.36

Dynabrade 54944 Throttle Ball Seat

1 × $29.36 -

×

Dynabrade 79799 6" 2500 Grit Dynasoft Finishing Film Non Vac Hook Face Disc, 25 per box

1 × $114.79

Dynabrade 79799 6" 2500 Grit Dynasoft Finishing Film Non Vac Hook Face Disc, 25 per box

1 × $114.79 -

×

Dynabrade 97416 Dowel Pin

1 × $2.07

Dynabrade 97416 Dowel Pin

1 × $2.07 -

×

Dynabrade 31013 Inside Wheel Flange

1 × $170.62

Dynabrade 31013 Inside Wheel Flange

1 × $170.62 -

×

Dynabrade 11217 Contact Arm Ass'y, 7/16" Dia. x 3/8" W, Steel Wheel, with 1/2" W Platen

1 × $91.11

Dynabrade 11217 Contact Arm Ass'y, 7/16" Dia. x 3/8" W, Steel Wheel, with 1/2" W Platen

1 × $91.11 -

×

Dynabrade 21694 NDDP1095RM, Pad Backing Plate, Aluminum

1 × $13.83

Dynabrade 21694 NDDP1095RM, Pad Backing Plate, Aluminum

1 × $13.83 -

×

Dynabrade 76009 6" Dia. Non-Vacuum Vinyl-Face Pad

1 × $23.94

Dynabrade 76009 6" Dia. Non-Vacuum Vinyl-Face Pad

1 × $23.94 -

×

Dynabrade 91711 DynaMesh 3" 600 Grit Hook & Loop Discs, 50 per box

1 × $26.42

Dynabrade 91711 DynaMesh 3" 600 Grit Hook & Loop Discs, 50 per box

1 × $26.42 -

×

Dynabrade 92190 2" W x 30" L 40 Grit A/Z DynaCut Belt, 10/pack

10 × $7.09

Dynabrade 92190 2" W x 30" L 40 Grit A/Z DynaCut Belt, 10/pack

10 × $7.09 -

×

Dynabrade 33340 Hanger Bracket Kit

1 × $48.94

Dynabrade 33340 Hanger Bracket Kit

1 × $48.94 -

×

Dynabrade 84854 3" x 4" Extra Fine Foam, Extreme Orange, 24 per pack

24 × $1.29

Dynabrade 84854 3" x 4" Extra Fine Foam, Extreme Orange, 24 per pack

24 × $1.29 -

×

Dynabrade 54806 Cylinder Assembly

1 × $135.36

Dynabrade 54806 Cylinder Assembly

1 × $135.36 -

×

Dynabrade 56815 5" Dia. Non-Vacuum Dynorbital Supreme Random Orbital Sander, 3/16 Orbit

1 × $269.00

Dynabrade 56815 5" Dia. Non-Vacuum Dynorbital Supreme Random Orbital Sander, 3/16 Orbit

1 × $269.00 -

×

Dynabrade 50399 Weight

1 × $26.91

Dynabrade 50399 Weight

1 × $26.91 -

×

Dynabrade 93347 Carbide Burr, 1/8" Dia., SL-42 D/C Burr, Taper-Radiused End, 1/2" Flute L, 1/8" Shank

1 × $16.97

Dynabrade 93347 Carbide Burr, 1/8" Dia., SL-42 D/C Burr, Taper-Radiused End, 1/2" Flute L, 1/8" Shank

1 × $16.97 -

×

Dynabrade 47801 .4 hp Right Angle Die Grinder, Front Exhaust, 15,000 RPM, 1/4" Collet

1 × $744.00

Dynabrade 47801 .4 hp Right Angle Die Grinder, Front Exhaust, 15,000 RPM, 1/4" Collet

1 × $744.00 -

×

Dynabrade 53606 Spindle

1 × $151.00

Dynabrade 53606 Spindle

1 × $151.00 -

×

Dynabrade 56037 Bearing Plate

1 × $30.25

Dynabrade 56037 Bearing Plate

1 × $30.25 -

×

Dynabrade 51926 Vane Set (4pk)

1 × $29.53

Dynabrade 51926 Vane Set (4pk)

1 × $29.53 -

×

Dynabrade 78687 D5 Cartridge Roll Mandrel 1/8" Pilot Dia. x 1" Pilot Length, 1/8" Shank Dia. x 1" Shank Length

1 × $4.54

Dynabrade 78687 D5 Cartridge Roll Mandrel 1/8" Pilot Dia. x 1" Pilot Length, 1/8" Shank Dia. x 1" Shank Length

1 × $4.54 -

×

Dynabrade 51605 6"-8" (152 mm-203 mm) Dia. Right Angle Two-Hand Rotary Deluxe Buffer

1 × $1,638.00

Dynabrade 51605 6"-8" (152 mm-203 mm) Dia. Right Angle Two-Hand Rotary Deluxe Buffer

1 × $1,638.00 -

×

Dynabrade 07106 Rotor

1 × $233.98

Dynabrade 07106 Rotor

1 × $233.98 -

×

Dynabrade 95446 Washer

1 × $5.49

Dynabrade 95446 Washer

1 × $5.49 -

×

Dynabrade 78303 1-1/2" Dia. x 1" W x 1/4" Shank, 40 Grit, A/O DynaCut Flap Wheel, 10/pack

10 × $46.90

Dynabrade 78303 1-1/2" Dia. x 1" W x 1/4" Shank, 40 Grit, A/O DynaCut Flap Wheel, 10/pack

10 × $46.90 -

×

Dynabrade 63982 - 1" 90 Dur. Contact Wheel Kit SuperFinisher

1 × $886.28

Dynabrade 63982 - 1" 90 Dur. Contact Wheel Kit SuperFinisher

1 × $886.28 -

×

Dynabrade 56880 5" Dia. Non-Vacuum Dynorbital Supreme Random Orbital Sander, 3/8" Orbit

1 × $269.00

Dynabrade 56880 5" Dia. Non-Vacuum Dynorbital Supreme Random Orbital Sander, 3/8" Orbit

1 × $269.00 -

×

Dynabrade 95936 Tune-Up Kit

1 × $216.33

Dynabrade 95936 Tune-Up Kit

1 × $216.33 -

×

Dynabrade 50350 7" (178 mm) Dia. Right Angle Depressed Center Wheel Grinder, 1.2 HP, 6,000 RPM, 5/8"-11 Spindle

1 × $1,646.00

Dynabrade 50350 7" (178 mm) Dia. Right Angle Depressed Center Wheel Grinder, 1.2 HP, 6,000 RPM, 5/8"-11 Spindle

1 × $1,646.00 -

×

Dynabrade 51130 Dynastraight Flapper Finishing Tool, 18,000 RPM, 1/4"20 Female Thread

1 × $519.00

Dynabrade 51130 Dynastraight Flapper Finishing Tool, 18,000 RPM, 1/4"20 Female Thread

1 × $519.00 -

×

Dynabrade 53215 Cup

1 × $95.66

Dynabrade 53215 Cup

1 × $95.66 -

×

Dynabrade 11617 Contact Wheel, 2" Dia. x 1" W x 5/8" I.D., Flat Face, 90 Duro Rubber

1 × $101.93

Dynabrade 11617 Contact Wheel, 2" Dia. x 1" W x 5/8" I.D., Flat Face, 90 Duro Rubber

1 × $101.93

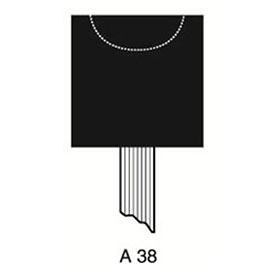

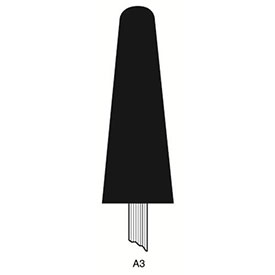

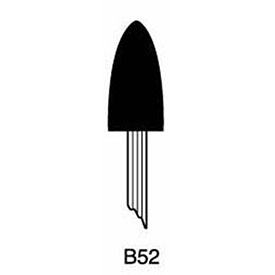

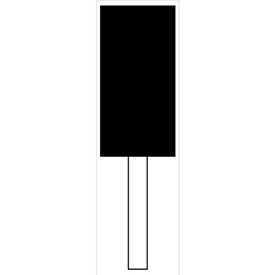

Standard Abrasives 877008, Unitized Mounted Point, 731 B121 x 1/8 in, 3M 7010310349

$5.85

Factory Stock, 7-10 Day Leadtime

Our Standard Abrasives Unitized Mounted Point lightly deburrs, blends and finishes metal and plastic parts. Choose from many different shapes and sizes to match specific small parts with hard-to-reach areas. Unitized mounted points deburr and finish without altering the shape of the workpiece, and self-dress to continually expose fresh mineral during use for efficient operations.