-

×

Dynabrade 57811 3-2/3" W x 7" L Dynabug Orbital Sander, Self-Generated Vacuum, .28 HP, 10,000 RPM, 3/32" Orbit

1 × $518.00

Dynabrade 57811 3-2/3" W x 7" L Dynabug Orbital Sander, Self-Generated Vacuum, .28 HP, 10,000 RPM, 3/32" Orbit

1 × $518.00 -

×

Dynabrade 96027 Screw

1 × $2.07

Dynabrade 96027 Screw

1 × $2.07 -

×

Dynabrade 07181 Spindle Assembly

1 × $148.60

Dynabrade 07181 Spindle Assembly

1 × $148.60 -

×

Dynabrade 54332 - 8" (203 mm) Dia. Non-Vacuum Gear-Driven Disc Pad, Hook-Face, Long Nap

1 × $37.06

Dynabrade 54332 - 8" (203 mm) Dia. Non-Vacuum Gear-Driven Disc Pad, Hook-Face, Long Nap

1 × $37.06 -

×

Dynabrade 53688 Guard

1 × $119.80

Dynabrade 53688 Guard

1 × $119.80 -

×

Dynabrade 53091 3/8" Pistol Grip Drill, .7 HP, Rear Exhaust, 950 RPM

1 × $1,194.00

Dynabrade 53091 3/8" Pistol Grip Drill, .7 HP, Rear Exhaust, 950 RPM

1 × $1,194.00 -

×

Dynabrade 79318 5" Dia. x 7/8" Center Hole, 80 Grit, A/O DynaCut Fiber Disc, 25/box

25 × $39.33

Dynabrade 79318 5" Dia. x 7/8" Center Hole, 80 Grit, A/O DynaCut Fiber Disc, 25/box

25 × $39.33 -

×

Dynabrade 91328 11-1/4" Dia. x 30 Micron A/O Hook "O"-style Vacuum Microfinishing Disc, 10/Box

10 × $9.80

Dynabrade 91328 11-1/4" Dia. x 30 Micron A/O Hook "O"-style Vacuum Microfinishing Disc, 10/Box

10 × $9.80 -

×

Dynabrade 04032 Nut

1 × $55.55

Dynabrade 04032 Nut

1 × $55.55 -

×

Dynabrade 15364 Nameplate, Electric Dynafile II

1 × $4.72

Dynabrade 15364 Nameplate, Electric Dynafile II

1 × $4.72 -

×

Dynabrade 15002 Vacuum Mini-Dynafile II Abrasive Belt Tool

1 × $813.00

Dynabrade 15002 Vacuum Mini-Dynafile II Abrasive Belt Tool

1 × $813.00 -

×

Dynabrade 64993 2" x 36" (51 mm x 914 mm) Electric Tool Post Grinder (Air Tension), 2 hp, 2,850 RPM, Wet, 230 V (AC), 1 Phase, 50 Hz

1 × $6,835.00

Dynabrade 64993 2" x 36" (51 mm x 914 mm) Electric Tool Post Grinder (Air Tension), 2 hp, 2,850 RPM, Wet, 230 V (AC), 1 Phase, 50 Hz

1 × $6,835.00 -

×

Dynabrade 60051 .1 hp Straight-Line Quick-Change Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet

1 × $1,025.00

Dynabrade 60051 .1 hp Straight-Line Quick-Change Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet

1 × $1,025.00 -

×

Dynabrade 91555 6" Non-Vacuum 100 Grit, Dynacut Extreme Orange Premium Film PSA Disc, 50/pack

1 × $42.77

Dynabrade 91555 6" Non-Vacuum 100 Grit, Dynacut Extreme Orange Premium Film PSA Disc, 50/pack

1 × $42.77 -

×

Dynabrade 50343 2" (51 mm) Dia. Depressed Center Grinder, .4 HP, 25,000 RPM, 3/8"-24 Spindle

1 × $637.50

Dynabrade 50343 2" (51 mm) Dia. Depressed Center Grinder, .4 HP, 25,000 RPM, 3/8"-24 Spindle

1 × $637.50 -

×

Dynabrade 04066 Felt Silencer

1 × $4.58

Dynabrade 04066 Felt Silencer

1 × $4.58 -

×

Dynabrade 98344 1/4" BulkHead

1 × $97.41

Dynabrade 98344 1/4" BulkHead

1 × $97.41 -

×

Dynabrade 21569 ND3036-1, Valve Assembly for EZQ-5

1 × $92.35

Dynabrade 21569 ND3036-1, Valve Assembly for EZQ-5

1 × $92.35

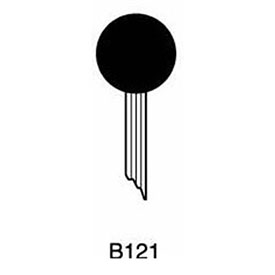

Standard Abrasives 877008, Unitized Mounted Point, 731 B121 x 1/8 in, 3M 7010310349

$5.85

Factory Stock, 7-10 Day Leadtime

Our Standard Abrasives Unitized Mounted Point lightly deburrs, blends and finishes metal and plastic parts. Choose from many different shapes and sizes to match specific small parts with hard-to-reach areas. Unitized mounted points deburr and finish without altering the shape of the workpiece, and self-dress to continually expose fresh mineral during use for efficient operations.