-

×

3M 92077, Disposable Earplugs, 92077H7-DC, 7 pairs/pack, 20 packs/case, 7100155188

20 × $2.43

3M 92077, Disposable Earplugs, 92077H7-DC, 7 pairs/pack, 20 packs/case, 7100155188

20 × $2.43 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00 -

×

3M 93726, PELTOR X4 Earmuffs X4A/37273(AAD), Over-the-Head, 10 EA/Case, 7000104073

1 × $326.49

3M 93726, PELTOR X4 Earmuffs X4A/37273(AAD), Over-the-Head, 10 EA/Case, 7000104073

1 × $326.49 -

×

Binks 46-6020, 66SD Air Cap

1 × $142.00

Binks 46-6020, 66SD Air Cap

1 × $142.00 -

×

Binks 72-84040, Die Cast Ball Valve 3/8" x 3/8"

1 × $64.23

Binks 72-84040, Die Cast Ball Valve 3/8" x 3/8"

1 × $64.23 -

×

Dynabrade 55521 .3hp, Straight-Line Die Grinder, 30,000 RPM, Aluminum Housing, Rear Exhaust, 1/4" Collet

1 × $417.00

Dynabrade 55521 .3hp, Straight-Line Die Grinder, 30,000 RPM, Aluminum Housing, Rear Exhaust, 1/4" Collet

1 × $417.00 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00 -

×

3M 11059, E-A-R, Soft SuperFit Earplugs 311-1254, Corded, Poly Bag, Regular Size, 2000 Pair/Case, 7000002307

1 × $762.08

3M 11059, E-A-R, Soft SuperFit Earplugs 311-1254, Corded, Poly Bag, Regular Size, 2000 Pair/Case, 7000002307

1 × $762.08 -

×

Binks PT-33-1, Tank Lid Gasket

1 × $31.96

Binks PT-33-1, Tank Lid Gasket

1 × $31.96 -

×

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

1 × $2,022.00

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

1 × $2,022.00 -

×

Binks 0811-7500-4, Airless 75M Gun Assembly

2 × $650.00

Binks 0811-7500-4, Airless 75M Gun Assembly

2 × $650.00 -

×

Binks MX3070PU-CAC3S55, MX3070PU, Pump System Cart Mounted

1 × $5,055.00

Binks MX3070PU-CAC3S55, MX3070PU, Pump System Cart Mounted

1 × $5,055.00 -

×

Dynabrade 01185 Vane Set (4pk)

1 × $26.54

Dynabrade 01185 Vane Set (4pk)

1 × $26.54 -

×

DeVilbiss AV-1239-704, Air Cap #704

2 × $67.06

DeVilbiss AV-1239-704, Air Cap #704

2 × $67.06 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00 -

×

DeVilbiss MBC-496-DEX, Fluid Needle

2 × $30.19

DeVilbiss MBC-496-DEX, Fluid Needle

2 × $30.19 -

×

Dynabrade 13509 Dynastraight Finishing Tool, Rear Exhaust, 6,000 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

1 × $1,245.00

Dynabrade 13509 Dynastraight Finishing Tool, Rear Exhaust, 6,000 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

1 × $1,245.00 -

×

Binks 6-229, Repair Kit, 2001 Series Gun

1 × $18.90

Binks 6-229, Repair Kit, 2001 Series Gun

1 × $18.90 -

×

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $533.42

Dynabrade 11254 Contact Arm Ass'y, 4-3/4" Dia. x 1/2" W

1 × $533.42 -

×

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00 -

×

3M 10052, E-A-R Classic Earplugs 310-1103, Uncorded, Small Size, Pillow Pack, 2000 Pair/Case, 7000127171

1 × $413.77

3M 10052, E-A-R Classic Earplugs 310-1103, Uncorded, Small Size, Pillow Pack, 2000 Pair/Case, 7000127171

1 × $413.77 -

×

DeVilbiss HAR-507, 60 CFM Air Regulator 507

1 × $108.41

DeVilbiss HAR-507, 60 CFM Air Regulator 507

1 × $108.41

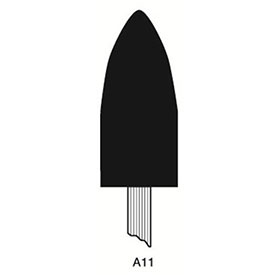

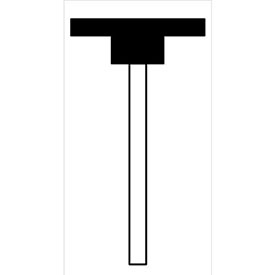

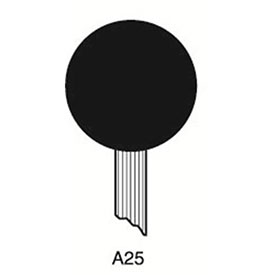

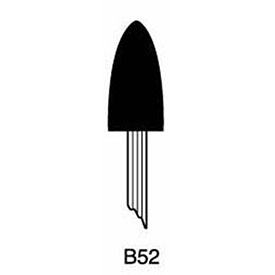

Standard Abrasives 877002, Unitized Mounted Point, 811 B52 x 1/8 in, 3M 7100025527

$7.34

Factory Stock, 7-10 Day Leadtime

Our Standard Abrasives Unitized Mounted Point lightly deburrs, blends and finishes metal and plastic parts. Choose from many different shapes and sizes to match specific small parts with hard-to-reach areas. Unitized mounted points deburr and finish without altering the shape of the workpiece, and self-dress to continually expose fresh mineral during use for efficient operations.