-

×

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67 -

×

3M 20911, PSA Cloth Disc 348D, 50 X-weight, 2 in x NH, Die 200P, 7000118871

200 × $0.82

3M 20911, PSA Cloth Disc 348D, 50 X-weight, 2 in x NH, Die 200P, 7000118871

200 × $0.82 -

×

3M 19677, Scotch-Seal Industrial Sealant 800, Reddish Brown, 1 Gallon Drum, 7000000793, 4/Case

4 × $251.59

3M 19677, Scotch-Seal Industrial Sealant 800, Reddish Brown, 1 Gallon Drum, 7000000793, 4/Case

4 × $251.59 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26 -

×

3M 47838, EMI Copper Foil Shielding Tape 1181, 23 in x 18 yd (58.42 cm x 16.5 m), 7000058121

1 × $1,436.53

3M 47838, EMI Copper Foil Shielding Tape 1181, 23 in x 18 yd (58.42 cm x 16.5 m), 7000058121

1 × $1,436.53 -

×

3M 14725, Foam and Fabric Spray Adhesive 24, Orange, 16 fl oz Can (Net Wt 13.8 oz), 7100179450, 12/Case

12 × $9.49

3M 14725, Foam and Fabric Spray Adhesive 24, Orange, 16 fl oz Can (Net Wt 13.8 oz), 7100179450, 12/Case

12 × $9.49 -

×

Standard Abrasives 843937, Quick Change Surface Conditioning GP Disc, 2560593, A/O Coarse, TSM, Brown, 7 in x 5/8"-11, 7000121657, 10/case

10 × $9.62

Standard Abrasives 843937, Quick Change Surface Conditioning GP Disc, 2560593, A/O Coarse, TSM, Brown, 7 in x 5/8"-11, 7000121657, 10/case

10 × $9.62 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00 -

×

3M 29827, Sanding Screen, 120 Grit, 19 in x NH, 7100160249

22 × $8.00

3M 29827, Sanding Screen, 120 Grit, 19 in x NH, 7100160249

22 × $8.00 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52 -

×

3M 29902, Sanding Screen, 150 Grit, 12 in x 18 in, 7100160763

20 × $4.84

3M 29902, Sanding Screen, 150 Grit, 12 in x 18 in, 7100160763

20 × $4.84 -

×

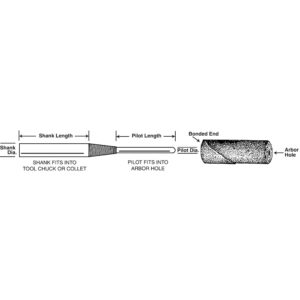

Standard Abrasives 713638, Cartridge RoII Mandrel, 3/32 in x 3/4 in x 1/8 in x 1 in x 2-3/4 in CM-2B, 7010294964

5 × $4.32

Standard Abrasives 713638, Cartridge RoII Mandrel, 3/32 in x 3/4 in x 1/8 in x 1 in x 2-3/4 in CM-2B, 7010294964

5 × $4.32 -

×

3M 94008, Scotch Super Glue Gel in Precision Applicator, AD125, .14 oz (4 g), 7100035277

36 × $2.42

3M 94008, Scotch Super Glue Gel in Precision Applicator, AD125, .14 oz (4 g), 7100035277

36 × $2.42 -

×

3M 98907, 3M Hand Tape Applicator 25 mm, 1 per case, 7010376216

1 × $44.95

3M 98907, 3M Hand Tape Applicator 25 mm, 1 per case, 7010376216

1 × $44.95 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 94733, Cubitron ll Cloth Belt 947A, 60+ X-weight, 3-1/2 in x 15-1/2 in, Fabri-lok, Single-flex, 7100093314, 50 per case

$7.71

Factory Stock, 7-10 Day Leadtime

Our 3M Cubitron II Abrasive Belt 947A built with 3M Precision-Shaped Grain cuts metal dramatically faster and cooler, and stays sharp longer than conventional ceramic belts. Its X-weight poly-cotton backing is flexible. This belt is optimized for low and medium pressure applications on stainless steel, mild steels, and aluminum.