-

×

Dynabrade 53183 Front Bearing Plate

1 × $38.94

Dynabrade 53183 Front Bearing Plate

1 × $38.94 -

×

Dynabrade 57101 5" Dia. Low Profile Random Orbital Sander

1 × $650.75

Dynabrade 57101 5" Dia. Low Profile Random Orbital Sander

1 × $650.75 -

×

Dynabrade 79109 1/2" W x 12" L 80 Grit DynaCut Premium Ceramic Belts, 50/pack

50 × $2.89

Dynabrade 79109 1/2" W x 12" L 80 Grit DynaCut Premium Ceramic Belts, 50/pack

50 × $2.89 -

×

Dynabrade X3262V - 3" Mini Extreme & 6" Extreme Random Orbital Sander, Vac, Combo Kit 12,000 RPM, 3/32" Dia., Rear Exhaust

2 × $381.74

Dynabrade X3262V - 3" Mini Extreme & 6" Extreme Random Orbital Sander, Vac, Combo Kit 12,000 RPM, 3/32" Dia., Rear Exhaust

2 × $381.74 -

×

Dynabrade 31653 Key

1 × $2.67

Dynabrade 31653 Key

1 × $2.67 -

×

Dynabrade 78646 1/2" Dia. x 1-1/2" W x 1/8" Center Hole, Z/A, 80 Grit, 100/pack

100 × $1.02

Dynabrade 78646 1/2" Dia. x 1-1/2" W x 1/8" Center Hole, Z/A, 80 Grit, 100/pack

100 × $1.02 -

×

Dynabrade 52410 3" Dia. 7 Degree Offset Disc Sander, Front Exhaust, .7 HP, 15,000 RPM, 3/8"-24 Thread

1 × $548.41

Dynabrade 52410 3" Dia. 7 Degree Offset Disc Sander, Front Exhaust, .7 HP, 15,000 RPM, 3/8"-24 Thread

1 × $548.41 -

×

Dynabrade 64253 Replacement Grip Top for 64700

1 × $636.70

Dynabrade 64253 Replacement Grip Top for 64700

1 × $636.70 -

×

Dynabrade 15025 Contact Arm Assembly, 3/8" Dia. x 1" W, 40 Durometer

1 × $86.21

Dynabrade 15025 Contact Arm Assembly, 3/8" Dia. x 1" W, 40 Durometer

1 × $86.21 -

×

Dynabrade 57737 Overskirt Shroud for Orbital Sander

1 × $37.26

Dynabrade 57737 Overskirt Shroud for Orbital Sander

1 × $37.26 -

×

Dynabrade 95972 Shim

1 × $2.46

Dynabrade 95972 Shim

1 × $2.46 -

×

Dynabrade 94534 Muffler

1 × $15.87

Dynabrade 94534 Muffler

1 × $15.87 -

×

Dynabrade Nitro Series MNF1 Mini-Nitrofile Abrasive Belt Tool

1 × $465.40

Dynabrade Nitro Series MNF1 Mini-Nitrofile Abrasive Belt Tool

1 × $465.40 -

×

Dynabrade 57572 5" Dia. Wet Dynorbital Supreme Random Orbital Sander, Basic, 3/16" Orbit

1 × $384.95

Dynabrade 57572 5" Dia. Wet Dynorbital Supreme Random Orbital Sander, Basic, 3/16" Orbit

1 × $384.95 -

×

Dynabrade 57841 Pad Top Assembly

1 × $100.49

Dynabrade 57841 Pad Top Assembly

1 × $100.49 -

×

Dynabrade 01743 Rear Bearing Plate

1 × $66.45

Dynabrade 01743 Rear Bearing Plate

1 × $66.45 -

×

Dynabrade 82442 6" Dia. x 60 Grit A/O Hook Non-Vacuum Film-Backed DynaCut Disc, 100/Box

100 × $1.63

Dynabrade 82442 6" Dia. x 60 Grit A/O Hook Non-Vacuum Film-Backed DynaCut Disc, 100/Box

100 × $1.63 -

×

Dynabrade 25365 Housing Assemblyy for 54744

1 × $247.61

Dynabrade 25365 Housing Assemblyy for 54744

1 × $247.61 -

×

Dynabrade 95051 Hex Key Wrench, 3/8"

1 × $5.96

Dynabrade 95051 Hex Key Wrench, 3/8"

1 × $5.96 -

×

Dynabrade 25257 Cup Nut

1 × $34.03

Dynabrade 25257 Cup Nut

1 × $34.03 -

×

Dynabrade 98393 - 10 Gauge Eq. Ground Wire Greeen w/yellow stripe

1 × $1.93

Dynabrade 98393 - 10 Gauge Eq. Ground Wire Greeen w/yellow stripe

1 × $1.93 -

×

Dynabrade 92758 3" W x 150' L 9 Micron A/O Lapping Film DynaCut Roll

1 × $178.44

Dynabrade 92758 3" W x 150' L 9 Micron A/O Lapping Film DynaCut Roll

1 × $178.44 -

×

Dynabrade 94775 2" W x 72" L 60 Grit A/Z DynaCut Belt, 10/pack

10 × $12.11

Dynabrade 94775 2" W x 72" L 60 Grit A/Z DynaCut Belt, 10/pack

10 × $12.11 -

×

Dynabrade 95541 Grease Gun

1 × $31.98

Dynabrade 95541 Grease Gun

1 × $31.98 -

×

Dynabrade 26833 Screw, Thumb, Lead, 10-32- Roller Guide Ass'y

1 × $68.91

Dynabrade 26833 Screw, Thumb, Lead, 10-32- Roller Guide Ass'y

1 × $68.91 -

×

Dynabrade 04009 Rotor

1 × $169.90

Dynabrade 04009 Rotor

1 × $169.90 -

×

Dynabrade 52662 1 hp Straight-Line Die Grinder, Rear Exhaust, 3,400 RPM, 1/4" Collet

1 × $849.29

Dynabrade 52662 1 hp Straight-Line Die Grinder, Rear Exhaust, 3,400 RPM, 1/4" Collet

1 × $849.29 -

×

Dynabrade 64329 Bracket

1 × $205.50

Dynabrade 64329 Bracket

1 × $205.50 -

×

Dynabrade 78421 7" Dia., Medium, Hook and Loop, DynaBrite NWN Surface Conditioning Disc, 25/pack

25 × $14.45

Dynabrade 78421 7" Dia., Medium, Hook and Loop, DynaBrite NWN Surface Conditioning Disc, 25/pack

25 × $14.45 -

×

Dynabrade 93096 3" Dia. x 120 Grit Premium Ceramic Non-Vacuum DynaCut, Locking-Type Disc, 3 Ply Cloth, 25/pack

25 × $2.09

Dynabrade 93096 3" Dia. x 120 Grit Premium Ceramic Non-Vacuum DynaCut, Locking-Type Disc, 3 Ply Cloth, 25/pack

25 × $2.09 -

×

Dynabrade 94523 Inlet Adapter Assembly

1 × $45.40

Dynabrade 94523 Inlet Adapter Assembly

1 × $45.40 -

×

Dynabrade 94532 Vacuum Adaptor

1 × $57.55

Dynabrade 94532 Vacuum Adaptor

1 × $57.55 -

×

Dynabrade 25297 Shim, 1.3Hp Governor, 1mm Thick

1 × $6.33

Dynabrade 25297 Shim, 1.3Hp Governor, 1mm Thick

1 × $6.33 -

×

Dynabrade 51412 7 Degree Offset Mini-Dynorbital Random Orbital Sander

1 × $856.29

Dynabrade 51412 7 Degree Offset Mini-Dynorbital Random Orbital Sander

1 × $856.29 -

×

Dynabrade 11717 Dynabelter Accu-Grinder Contact Arm Assembly, 2 Inch Dia x 1 Inch, 90 Durometer, Serrated Wheel

1 × $644.05

Dynabrade 11717 Dynabelter Accu-Grinder Contact Arm Assembly, 2 Inch Dia x 1 Inch, 90 Durometer, Serrated Wheel

1 × $644.05 -

×

Dynabrade 95838 Screw

1 × $1.93

Dynabrade 95838 Screw

1 × $1.93 -

×

Dynabrade 64437 Housing for Model 58406

1 × $113.48

Dynabrade 64437 Housing for Model 58406

1 × $113.48 -

×

Dynabrade 93688 Spindle

1 × $158.60

Dynabrade 93688 Spindle

1 × $158.60 -

×

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86

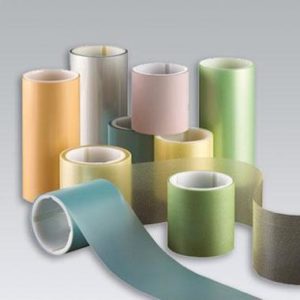

3M 74325, Cloth Belt 963G, 60 YN-weight, 4 in x 132 in, Film-lok, Single-flex, 7010307737, 25 per case

$27.26

Factory Stock, 7-10 Day Leadtime

3M Cloth Belt 963G features high-performing 3M Ceramic Abrasive Grain on a durable polyester blend backing to give you outstanding durability and cutting efficiency in high pressure applications on carbon steel, tool steels, and hardwoods.

3M Cloth Belt 963G can run wet or dry and offers significant productivity gains for applications such as rapid stock removal, grinding, blending on steel, and high pressure stock removal on wood. We recommend this belt for wet or dry grinding of carbon and tool steel in medium to high pressure applications such as rapid grinding systems or coated abrasive machining applications. The heavyweight backing supports demanding applications and a consistent cut-rate, and is resin-bonded to withstand high heat and pressure.

Proprietary 3M Ceramic Abrasive Grain is a ceramic mineral chemically engineered with a unique “stay sharp” crystalline structure, which continually reveals fresh cutting edges on the surface of the work piece ensuring a sustained cut. The grain is formed using a proprietary process to enhance toughness and hardness of the grain, for long product life and significant productivity benefits. Abrasives made with 3M ceramic abrasive grain have outstanding durability and improved cutting efficiencies. These products have a long service life, cut exceptionally fast, and can stand up to high pressure production environments even on the toughest materials.

Abrasive belts come in many different widths and lengths and are used on a variety of different belt sanding tools for many different applications on both wood and metal. At 3M we offer a broad selection of belts to fit most any industrial belt sander. Wider belts are used with wide belt sanders to dimension or finish wood panels, smooth rough cut edges of metal sheets, or add a grain pattern to stainless steel sheets. Medium-width belts fit onto edge sanders for sanding flat, narrow surfaces such as panel edges; and narrow belts are used with portable belt sanders for sanding or blending wood pieces such as cabinet doors.

Belts come with various flexibilities and splices that join the belt ends. 3M Cloth Belt 963G has a film splice for added strength when grinding in high pressure applications. When greater flexibility may be needed to increase conformity or for a softer touch for finishing and blending, an L-flex provides more flexibility than the standard flex, and a fullflex belt is the most flexible.