-

×

Dynabrade 51225 2" Dia. Right Angle Disc Sander, Self-Generated Vacuum, 12,000 RPM

1 × $650.76

Dynabrade 51225 2" Dia. Right Angle Disc Sander, Self-Generated Vacuum, 12,000 RPM

1 × $650.76 -

×

Dynabrade 02174 Housing for Model 52405

1 × $102.11

Dynabrade 02174 Housing for Model 52405

1 × $102.11 -

×

Dynabrade 40553 Spiral Bevel Gear

1 × $117.07

Dynabrade 40553 Spiral Bevel Gear

1 × $117.07 -

×

Dynabrade 40758 Spanner Wrench

1 × $20.29

Dynabrade 40758 Spanner Wrench

1 × $20.29 -

×

Dynabrade 33647 ND6560, End Cap Gasket

1 × $3.65

Dynabrade 33647 ND6560, End Cap Gasket

1 × $3.65 -

×

Dynabrade 56624 Housing for Model 59008; 12,000 RPM

1 × $95.66

Dynabrade 56624 Housing for Model 59008; 12,000 RPM

1 × $95.66 -

×

Dynabrade 12167 Bearing

1 × $47.86

Dynabrade 12167 Bearing

1 × $47.86 -

×

Dynabrade 11010 Spring

1 × $7.51

Dynabrade 11010 Spring

1 × $7.51 -

×

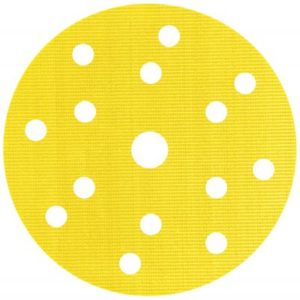

Dynabrade 56297 6" Dia. Vacuum Disc Pad, 8-6-1 Holes, Hook-Face, Short Nap

1 × $37.55

Dynabrade 56297 6" Dia. Vacuum Disc Pad, 8-6-1 Holes, Hook-Face, Short Nap

1 × $37.55 -

×

Dynabrade 02339 Lock Nut

1 × $25.12

Dynabrade 02339 Lock Nut

1 × $25.12 -

×

Dynabrade 90334 3/4" W x 20-1/2" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.40

Dynabrade 90334 3/4" W x 20-1/2" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.40 -

×

Dynabrade 31986 Hose Cuff Clip

1 × $36.55

Dynabrade 31986 Hose Cuff Clip

1 × $36.55 -

×

Dynabrade 51302 .5 hp Straight-Line Die Grinder, Front Exhaust, 20,000 RPM, 1/4" Collet

1 × $431.21

Dynabrade 51302 .5 hp Straight-Line Die Grinder, Front Exhaust, 20,000 RPM, 1/4" Collet

1 × $431.21 -

×

Dynabrade 11809 Tension Cam

1 × $77.83

Dynabrade 11809 Tension Cam

1 × $77.83 -

×

Dynabrade 15131 Nylon Shoulder Washer, Black

1 × $1.93

Dynabrade 15131 Nylon Shoulder Washer, Black

1 × $1.93 -

×

Dynabrade 51963 Rear Flange

1 × $84.28

Dynabrade 51963 Rear Flange

1 × $84.28 -

×

Dynabrade 76010 - 5" (127 mm) Dia. Hook-Face Vacuum Pad

1 × $23.18

Dynabrade 76010 - 5" (127 mm) Dia. Hook-Face Vacuum Pad

1 × $23.18 -

×

Dynabrade 96584 Vacuum Hose- 3/4" x 2-1/2"

1 × $13.66

Dynabrade 96584 Vacuum Hose- 3/4" x 2-1/2"

1 × $13.66 -

×

Dynabrade 59119 3" Dia. HiVac Dynorbital-Spirit Mesh Abrasive System, Self-Generated Vacuum, 3/32" Orbit

1 × $307.30

Dynabrade 59119 3" Dia. HiVac Dynorbital-Spirit Mesh Abrasive System, Self-Generated Vacuum, 3/32" Orbit

1 × $307.30 -

×

Dynabrade 14347 Spacer

1 × $36.49

Dynabrade 14347 Spacer

1 × $36.49 -

×

Dynabrade 78350 6" Dia. x 1/2" W x 1" Center Hole, 8A Medium, S/C DynaBrite Deburring Convolute Wheel, 2/box

2 × $61.85

Dynabrade 78350 6" Dia. x 1/2" W x 1" Center Hole, 8A Medium, S/C DynaBrite Deburring Convolute Wheel, 2/box

2 × $61.85 -

×

Dynabrade 64993 2" x 36" (51 mm x 914 mm) Electric Tool Post Grinder (Air Tension), 2 hp, 2,850 RPM, Wet, 230 V (AC), 1 Phase, 50 Hz

1 × $6,512.65

Dynabrade 64993 2" x 36" (51 mm x 914 mm) Electric Tool Post Grinder (Air Tension), 2 hp, 2,850 RPM, Wet, 230 V (AC), 1 Phase, 50 Hz

1 × $6,512.65 -

×

Dynabrade 25119 Housing Ass'y for Model 54359

1 × $131.31

Dynabrade 25119 Housing Ass'y for Model 54359

1 × $131.31 -

×

Dynabrade 33655 ND6690, Water Fitting Clip

1 × $9.81

Dynabrade 33655 ND6690, Water Fitting Clip

1 × $9.81 -

×

Dynabrade 31637 Cover

1 × $168.37

Dynabrade 31637 Cover

1 × $168.37 -

×

Dynabrade 94315 Air Pressure Gauge

1 × $120.44

Dynabrade 94315 Air Pressure Gauge

1 × $120.44 -

×

Dynabrade 18749 Spanner Wrench

1 × $6.03

Dynabrade 18749 Spanner Wrench

1 × $6.03 -

×

Dynabrade 53709 Housing for Model 13509; 6,000 RPM

1 × $168.29

Dynabrade 53709 Housing for Model 13509; 6,000 RPM

1 × $168.29 -

×

Dynabrade 51072 Coupling

1 × $39.72

Dynabrade 51072 Coupling

1 × $39.72 -

×

Dynabrade 90753 5" Dia. x 2" W, Coarse, Non-Woven DynaBrite Band, 10/pack

10 × $44.28

Dynabrade 90753 5" Dia. x 2" W, Coarse, Non-Woven DynaBrite Band, 10/pack

10 × $44.28 -

×

Dynabrade 51812 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 3/32" Collet

1 × $715.47

Dynabrade 51812 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 3/32" Collet

1 × $715.47 -

×

Dynabrade 78412 3" Dia. x 1" W x 1/4" Shank, 120 Grit, A/O DynaCut Flap Wheel

1 × $17.45

Dynabrade 78412 3" Dia. x 1" W x 1/4" Shank, 120 Grit, A/O DynaCut Flap Wheel

1 × $17.45 -

×

Dynabrade 39020 - 2 1/4"Roto Peen Hub Assy/01612

1 × $700.37

Dynabrade 39020 - 2 1/4"Roto Peen Hub Assy/01612

1 × $700.37 -

×

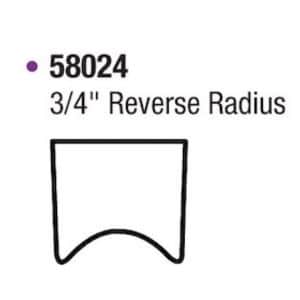

Dynabrade 58024 - 3/4" (19 mm) Dia. Non-Vacuum Dynafine Backsplash Reverse Radius Disc Pad, Vinyl-Face

1 × $33.47

Dynabrade 58024 - 3/4" (19 mm) Dia. Non-Vacuum Dynafine Backsplash Reverse Radius Disc Pad, Vinyl-Face

1 × $33.47 -

×

Dynabrade 52301 Vacuum Shroud

1 × $421.62

Dynabrade 52301 Vacuum Shroud

1 × $421.62 -

×

Dynabrade 47822 2" Dia. Right Angle Disc Sander

1 × $662.11

Dynabrade 47822 2" Dia. Right Angle Disc Sander

1 × $662.11 -

×

Dynabrade 63987 - 3" 70 Dur. Contact Wheel Kit SuperFinisher

1 × $779.58

Dynabrade 63987 - 3" 70 Dur. Contact Wheel Kit SuperFinisher

1 × $779.58 -

×

Dynabrade 15336 Rubber Drive Wheel

1 × $71.38

Dynabrade 15336 Rubber Drive Wheel

1 × $71.38 -

×

Dynabrade 78855 Knot Wire End Brush 1-1/8" Dia. x .014 x 7/8" Steel

1 × $24.89

Dynabrade 78855 Knot Wire End Brush 1-1/8" Dia. x .014 x 7/8" Steel

1 × $24.89 -

×

Dynabrade 11012 Idler Wheel Assembly

1 × $72.15

Dynabrade 11012 Idler Wheel Assembly

1 × $72.15 -

×

Dynabrade 97083 Screw

1 × $1.93

Dynabrade 97083 Screw

1 × $1.93 -

×

Dynabrade 15350 Contact Arm Assembly, 1 Dia. x 2 W, Serrated Wheel, 90 Durometer

1 × $199.04

Dynabrade 15350 Contact Arm Assembly, 1 Dia. x 2 W, Serrated Wheel, 90 Durometer

1 × $199.04 -

×

Dynabrade 95574 Dowel Pin, Steel, 1/8" x 1-1/4"

1 × $1.93

Dynabrade 95574 Dowel Pin, Steel, 1/8" x 1-1/4"

1 × $1.93 -

×

Dynabrade 25231 Gear Set 1.473: 1 Ratio, 1.3 hp

1 × $365.72

Dynabrade 25231 Gear Set 1.473: 1 Ratio, 1.3 hp

1 × $365.72 -

×

Dynabrade 21464 ND1080RM, Trigger Only

1 × $24.36

Dynabrade 21464 ND1080RM, Trigger Only

1 × $24.36 -

×

Dynabrade 02438 3 hp Housing Assembly for 53245

1 × $411.04

Dynabrade 02438 3 hp Housing Assembly for 53245

1 × $411.04 -

×

Dynabrade 54387 .7 hp Right Angle Die Grinder, Rear Exhaust, 18,000 RPM, 1/4" Collet

1 × $975.24

Dynabrade 54387 .7 hp Right Angle Die Grinder, Rear Exhaust, 18,000 RPM, 1/4" Collet

1 × $975.24 -

×

Dynabrade 50583 Brush 5" Vac Shroud, 1 1/4" High x 19 1/16" L.

1 × $47.03

Dynabrade 50583 Brush 5" Vac Shroud, 1 1/4" High x 19 1/16" L.

1 × $47.03 -

×

Dynabrade 62106 - 5" (127 mm) Non-Vacuum Urethane Disc Pad, Standard

1 × $26.00

Dynabrade 62106 - 5" (127 mm) Non-Vacuum Urethane Disc Pad, Standard

1 × $26.00 -

×

Dynabrade Nitro Series 50209 Polisher Kit, w/ RB3 Buffer

1 × $365.65

Dynabrade Nitro Series 50209 Polisher Kit, w/ RB3 Buffer

1 × $365.65 -

×

Dynabrade 58406 6" Dia. Two-Hand Dynorbital Random Orbital Sander, Self-Generated Vacuum

1 × $574.65

Dynabrade 58406 6" Dia. Two-Hand Dynorbital Random Orbital Sander, Self-Generated Vacuum

1 × $574.65 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 7100231078, Cloth Belt 340D, 80 X-weight, 4 in x 24 in, Film-lok, Single-flex, 50 per case

$4.77

Factory Stock, 7-10 Day Leadtime

3M Cloth Belt 340D is our open coat premium grade aluminum oxide cloth belt that provides durability for aggressive stock removal, resists loading, and is suitable for a variety of applications on wood and metal. We recommended this belt for wide belt sanding, edge sanding, or portable belt sanding.

Fast-cutting aluminum oxide abrasive grains are resin-bonded to a durable cotton cloth backing to provide continuous cut and long-life. Our open coat and load-resistant coating make this belt particularly favorable for sanding soft woods. Additionally, the washable backing is suitable for high production environments where the belt may need washing at intervals to remove soft wood resin or pitch buildup.

Aluminum oxide mineral is a popular choice among industrial professionals because of its cut-rate, durability, and long life. It can be used on a wide variety of materials in both woodworking and metalworking, including ferrous alloys, and is the most commonly used industrial abrasive. The abrasive particles are adhered to the cloth backing with resin, creating a strong bond that withstands high heat and pressure.

Abrasive belts come in many different widths and lengths and are used on a variety of different belt sanding tools for many different applications on both wood and metal. At 3M we offer a broad selection of belts to fit most any industrial belt sander. Wider belts are used with wide belt sanders to dimension or finish wood panels, smooth rough cut edges of metal sheets, or add a grain pattern to stainless steel sheets. Medium-width belts fit onto edge sanders for sanding flat, narrow surfaces such as panel edges; and narrow belts are used with portable belt sanders for sanding or blending wood pieces such as cabinet doors.

Belts come with various splices that join the belt ends. A film media splice achieves a secure bond with a joining film that minimizes chatter marks, ensures a smooth running belt, and produces consistent finishing results. A sine wave splice is constructed of interlocking fingers that enable the splice to travel smoothly over contact wheels, reduce hinging, and provide added strength to the joint area. Sine wave splices are typically used for coarser grades and wide belts as well as on belts that are going to be washed.