-

×

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

600 × $6.03

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

600 × $6.03 -

×

3M 45718, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 5 in x NH, D/F 5HL, Die 500FH, 7100113075

200 × $1.78

3M 45718, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 5 in x NH, D/F 5HL, Die 500FH, 7100113075

200 × $1.78 -

×

3M 27008, 642WY, 3" X 30", 50000 Mesh, Diamond Cloth Belts, 7010533172

1 × $147.65

3M 27008, 642WY, 3" X 30", 50000 Mesh, Diamond Cloth Belts, 7010533172

1 × $147.65 -

×

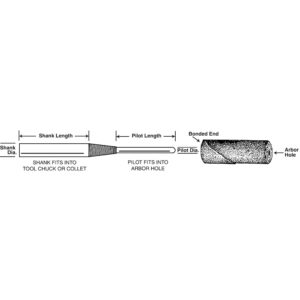

Standard Abrasives 710190, Cartridge Roll Mandrel, 2560020, 1/8 in x 1 in x 1/4 in x 1-1/4 in x 2-3/4 in CM-9, 7000121790

5 × $4.17

Standard Abrasives 710190, Cartridge Roll Mandrel, 2560020, 1/8 in x 1 in x 1/4 in x 1-1/4 in x 2-3/4 in CM-9, 7000121790

5 × $4.17 -

×

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

2 × $746.76

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

2 × $746.76 -

×

3M 62791, Polyurethane Adhesive Sealant 550FC Fast Cure, White, 310 mL Cartridge, 7000000932, 12/Case

12 × $11.11

3M 62791, Polyurethane Adhesive Sealant 550FC Fast Cure, White, 310 mL Cartridge, 7000000932, 12/Case

12 × $11.11 -

×

Standard Abrasives 713159, Aluminum Oxide Handy Roll, P120 J-weight, 1-1/2 in x 50 yd, 7010290409

1 × $37.54

Standard Abrasives 713159, Aluminum Oxide Handy Roll, P120 J-weight, 1-1/2 in x 50 yd, 7010290409

1 × $37.54 -

×

3M 25124, Scotch-Weld Threadlocker TL42, Blue, 1 L Bottle, 7010310189, 1/case

1 × $319.64

3M 25124, Scotch-Weld Threadlocker TL42, Blue, 1 L Bottle, 7010310189, 1/case

1 × $319.64 -

×

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

200 × $0.97

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

200 × $0.97 -

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14 -

×

3M 16348, PPS Liners, Mini (6 fl oz, 200 mL), 7100067924

100 × $147.38

3M 16348, PPS Liners, Mini (6 fl oz, 200 mL), 7100067924

100 × $147.38 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76 -

×

ACS Diamond Cloth Belt, CX1250 3" X 90" 20U

2 × $171.30

ACS Diamond Cloth Belt, CX1250 3" X 90" 20U

2 × $171.30 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23 -

×

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

600 × $1.74

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

600 × $1.74 -

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

400 × $1.50

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

400 × $1.50 -

×

3M 71347, 641WY, 3" X 30", 220 Mesh, Diamond Cloth Belts, 7010534831

1 × $137.54

3M 71347, 641WY, 3" X 30", 220 Mesh, Diamond Cloth Belts, 7010534831

1 × $137.54 -

×

3M 50010, VentureClad Insulation Jacketing Tape 1577CW-WME, White, 99 mm x 13.7 m, 7010379907

12 × $44.16

3M 50010, VentureClad Insulation Jacketing Tape 1577CW-WME, White, 99 mm x 13.7 m, 7010379907

12 × $44.16 -

×

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

2 × $0.86

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

2 × $0.86 -

×

3M 94700, Cubitron ll Cloth Belt 947A, 60+ X-weight, 1/4 in x 24 in, Fabri-lok, Single-flex, 7010360589, 200 per case

1 × $2.40

3M 94700, Cubitron ll Cloth Belt 947A, 60+ X-weight, 1/4 in x 24 in, Fabri-lok, Single-flex, 7010360589, 200 per case

1 × $2.40 -

×

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52 -

×

3M 08742, Inhalation Valve 7282, 7000125986, 200 EA/Case

1 × $428.74

3M 08742, Inhalation Valve 7282, 7000125986, 200 EA/Case

1 × $428.74 -

×

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

400 × $1.25

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

400 × $1.25 -

×

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

1000 × $0.73

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

1000 × $0.73 -

×

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39 -

×

3M 20274, Neoprene Contact Adhesive 10, Light Yellow, 1 Gallon Can, 7000144610, 4/case

4 × $112.37

3M 20274, Neoprene Contact Adhesive 10, Light Yellow, 1 Gallon Can, 7000144610, 4/case

4 × $112.37 -

×

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

1000 × $0.67

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

1000 × $0.67 -

×

3M 50023, Venture Tape UL181B-FX Mastik Foil Tape 1580-P, Silver, 1581A, 2 in x 100 ft, 7010337393

24 × $41.91

3M 50023, Venture Tape UL181B-FX Mastik Foil Tape 1580-P, Silver, 1581A, 2 in x 100 ft, 7010337393

24 × $41.91 -

×

3M 19674, Scotch-Seal Industrial Sealant 800, Reddish Brown, 5 oz Tube, 7000000792, 36/Case

36 × $23.31

3M 19674, Scotch-Seal Industrial Sealant 800, Reddish Brown, 5 oz Tube, 7000000792, 36/Case

36 × $23.31 -

×

3M 26022, PPS Series 2.0 Adapter, Type S12, 10 mm Male, 1.0 mm Thread, 7100135943

1 × $25.96

3M 26022, PPS Series 2.0 Adapter, Type S12, 10 mm Male, 1.0 mm Thread, 7100135943

1 × $25.96 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58 -

×

Norton 66261014936 3" DIA X 1/8" Thick, Bear-Tex NEX Rapid Blend Quick-Change Type III Non-Woven Unified Wheel, 40 Each

40 × $11.64

Norton 66261014936 3" DIA X 1/8" Thick, Bear-Tex NEX Rapid Blend Quick-Change Type III Non-Woven Unified Wheel, 40 Each

40 × $11.64 -

×

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57 -

×

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

2 × $2,225.47

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

2 × $2,225.47 -

×

3M 11418, Roloc Disc 361F, P240 XF-weight, TR, 3 in, Die R300V, 7000045106

200 × $1.25

3M 11418, Roloc Disc 361F, P240 XF-weight, TR, 3 in, Die R300V, 7000045106

200 × $1.25 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

1500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

1500 × $0.60 -

×

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06 -

×

3M 90335, Scotch Super Glue Liquid AD118D, .07 oz, 7000047660

36 × $0.77

3M 90335, Scotch Super Glue Liquid AD118D, .07 oz, 7000047660

36 × $0.77 -

×

ACS Diamond Cloth Belt, CX1250 1" X 72" 125U

6 × $45.50

ACS Diamond Cloth Belt, CX1250 1" X 72" 125U

6 × $45.50 -

×

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33 -

×

3M 26432, PPS Series 2.0 Sealing Plug, 96 plugs per pack, 7100135627

6 × $11.95

3M 26432, PPS Series 2.0 Sealing Plug, 96 plugs per pack, 7100135627

6 × $11.95 -

×

3M 45709, Cubitron II Hookit Cloth Disc 947A, 80+ X-weight, 6 in x NH, Die 600Z, 7100113080

200 × $2.81

3M 45709, Cubitron II Hookit Cloth Disc 947A, 80+ X-weight, 6 in x NH, Die 600Z, 7100113080

200 × $2.81 -

×

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51 -

×

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,520.00

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,520.00 -

×

3M 27423, Cloth Belt 340D, 80 X-weight, 6 in x 48 in, Film-lok, Single-flex, 7100231504, 20 per case

20 × $10.98

3M 27423, Cloth Belt 340D, 80 X-weight, 6 in x 48 in, Film-lok, Single-flex, 7100231504, 20 per case

20 × $10.98 -

×

3M 94733, Cubitron ll Cloth Belt 947A, 60+ X-weight, 3-1/2 in x 15-1/2 in, Fabri-lok, Single-flex, 7100093314, 50 per case

50 × $7.71

3M 94733, Cubitron ll Cloth Belt 947A, 60+ X-weight, 3-1/2 in x 15-1/2 in, Fabri-lok, Single-flex, 7100093314, 50 per case

50 × $7.71 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26 -

×

3M 25140, Scotch-Weld Threadlocker TL43, Blue, 250 mL Bottle, 7100039221, 2/case

2 × $126.95

3M 25140, Scotch-Weld Threadlocker TL43, Blue, 250 mL Bottle, 7100039221, 2/case

2 × $126.95 -

×

3M 94717, Cubitron ll Cloth Belt 947A, 80+ X-weight, 1 in x 30 in, Fabri-lok, Single-flex, 7010294445, 200 per case

200 × $3.73

3M 94717, Cubitron ll Cloth Belt 947A, 80+ X-weight, 1 in x 30 in, Fabri-lok, Single-flex, 7010294445, 200 per case

200 × $3.73 -

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00 -

×

3M 20932, PSA Cloth Disc 348D, 80 X-weight, 1 in x NH, Die 100N, 7000118914

500 × $0.40

3M 20932, PSA Cloth Disc 348D, 80 X-weight, 1 in x NH, Die 100N, 7000118914

500 × $0.40 -

×

3M 62611, Scotch-Weld Threadlocker TL62, Red, 250 mL Bottle, 7100039195, 2/case

2 × $100.85

3M 62611, Scotch-Weld Threadlocker TL62, Red, 250 mL Bottle, 7100039195, 2/case

2 × $100.85 -

×

3M 88903, PSA Cloth Disc 348D, 60 X-weight, 12 in x NH, Die 1200B, 7000118896

10 × $7.75

3M 88903, PSA Cloth Disc 348D, 60 X-weight, 12 in x NH, Die 1200B, 7000118896

10 × $7.75

3M 69386, Trizact Cloth Belt 237AA, A65 X-weight, 3-1/2 in x 15-1/2 in, Film-lok, Full-flex, 7000028337, 50 per case

$11.59

Factory Stock, 7-10 Day Leadtime

3M Trizact Cloth Belt 237AA uses proprietary microreplication technology by 3M where micron-graded aluminum oxide particles are formed into tiny pyramids of abrasive mineral and then coated on an X weight cloth backing. As these pyramids wear, fresh, sharp mineral is continually exposed to produce a consistent cut and a predictable, fine finish.