-

×

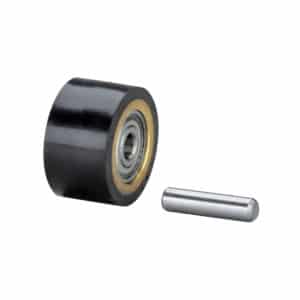

Dynabrade 65238 Drive Wheel

1 × $850.41

Dynabrade 65238 Drive Wheel

1 × $850.41 -

×

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $34.87

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $34.87 -

×

Dynabrade 78466 2" Dia. x 3/4", 8-32 Female Center Thread, A/O, 80 Grit, 8-Ply J-DynaCut Cross Pad, 100/pack

100 × $189.00

Dynabrade 78466 2" Dia. x 3/4", 8-32 Female Center Thread, A/O, 80 Grit, 8-Ply J-DynaCut Cross Pad, 100/pack

100 × $189.00 -

×

Dynabrade 59179 6" Dia. Dynorbital-Spirit Random Orbital Sander, Non-Vacuum, 3/16" Orbit

1 × $206.55

Dynabrade 59179 6" Dia. Dynorbital-Spirit Random Orbital Sander, Non-Vacuum, 3/16" Orbit

1 × $206.55 -

×

Dynabrade 54746 4" (102 mm) Dia. Extended Right Angle Type 1 Cut-Off Tool, Steel Housing, .7 HP, 13,500 RPM, 3/8"-24 Spindle

1 × $1,144.92

Dynabrade 54746 4" (102 mm) Dia. Extended Right Angle Type 1 Cut-Off Tool, Steel Housing, .7 HP, 13,500 RPM, 3/8"-24 Spindle

1 × $1,144.92 -

×

Dynabrade 50010 Collet, 3/8"-24 Female Thread, 1/4" Capacity, 3-Piece Collet

1 × $77.83

Dynabrade 50010 Collet, 3/8"-24 Female Thread, 1/4" Capacity, 3-Piece Collet

1 × $77.83 -

×

Dynabrade 51455 5"-8" (127 mm-203 mm) Dia. 7 Degree Offest Two-Hand Rotary Buffer

1 × $882.53

Dynabrade 51455 5"-8" (127 mm-203 mm) Dia. 7 Degree Offest Two-Hand Rotary Buffer

1 × $882.53 -

×

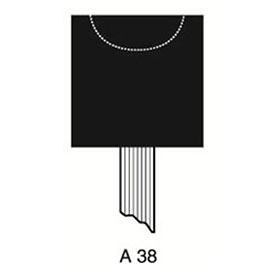

Dynabrade 78722 1" x 1"-A38 Dynacut A/O Mounted Point, 5/pack

5 × $1.84

Dynabrade 78722 1" x 1"-A38 Dynacut A/O Mounted Point, 5/pack

5 × $1.84 -

×

Dynabrade 53522 Polisher (Double Extension), 1 HP, 3,400 RPM, 1/2"-20 Spindle Thread

1 × $1,434.43

Dynabrade 53522 Polisher (Double Extension), 1 HP, 3,400 RPM, 1/2"-20 Spindle Thread

1 × $1,434.43 -

×

Dynabrade 11203 Contact Arm Ass'y, 5/8" Dia. x 3/8" W, Rubber Wheel, with 1/2" W Platen

1 × $70.16

Dynabrade 11203 Contact Arm Ass'y, 5/8" Dia. x 3/8" W, Rubber Wheel, with 1/2" W Platen

1 × $70.16

3M 69367, Trizact Cloth Belt 237AA, A16 X-weight, 1/2 in x 24 in, Film-lok, Full-flex, 7010292266, 200 per case

$4.24

Factory Stock, 7-10 Day Leadtime

3M Trizact Cloth Belt 237AA uses proprietary microreplication technology by 3M where micron-graded aluminum oxide particles are formed into tiny pyramids of abrasive mineral and then coated on an X weight cloth backing. As these pyramids wear, fresh, sharp mineral is continually exposed to produce a consistent cut and a predictable, fine finish.