-

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00 -

×

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70 -

×

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95 -

×

3M 92577, Temflex Vinyl Electrical Tape 165, Yellow, 3/4 in x 60 ft (19 mm x 18 m), 6 mil, 7100169490

10 × $1.59

3M 92577, Temflex Vinyl Electrical Tape 165, Yellow, 3/4 in x 60 ft (19 mm x 18 m), 6 mil, 7100169490

10 × $1.59 -

×

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

400 × $1.50

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

400 × $1.50 -

×

3M 65086, Scotch-Brite Diamond Wheel, 6" x 1" x 1" 645DC, 7010329878

1 × $945.02

3M 65086, Scotch-Brite Diamond Wheel, 6" x 1" x 1" 645DC, 7010329878

1 × $945.02 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

1000 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

1000 × $0.75 -

×

3M 05612, Polyurethane Glass Adhesive Sealant 590, Black, 600 mL Sausage Pack, 7000121536, 12/Case

12 × $19.64

3M 05612, Polyurethane Glass Adhesive Sealant 590, Black, 600 mL Sausage Pack, 7000121536, 12/Case

12 × $19.64 -

×

3M 71355, 663FC, 2" X 48", 70u, Diamond Trizact Belts, 7010534884

1 × $511.22

3M 71355, 663FC, 2" X 48", 70u, Diamond Trizact Belts, 7010534884

1 × $511.22 -

×

3M 85492, Scotch Foil Tape 3311, Silver, 2 in x 10 yd, 3.6 mil, 2MMX1200M, 7010334860

24 × $5.52

3M 85492, Scotch Foil Tape 3311, Silver, 2 in x 10 yd, 3.6 mil, 2MMX1200M, 7010334860

24 × $5.52 -

×

3M 34556, Cubitron II Net Sheet Roll, 320+, 80 mm x 10 m, 7100283765, 6 Rolls/Case

6 × $28.94

3M 34556, Cubitron II Net Sheet Roll, 320+, 80 mm x 10 m, 7100283765, 6 Rolls/Case

6 × $28.94 -

×

3M 29836, Sanding Screen, 60 Grit, 18 in x NH, 7100160820

12 × $11.06

3M 29836, Sanding Screen, 60 Grit, 18 in x NH, 7100160820

12 × $11.06 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

1000 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

1000 × $0.67 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

1000 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

1000 × $0.58 -

×

ACS Diamond Cloth Belt, CX1250 3/8" X 120" 125U

16 × $27.50

ACS Diamond Cloth Belt, CX1250 3/8" X 120" 125U

16 × $27.50 -

×

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67 -

×

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $1,012.00

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $1,012.00 -

×

3M 56038, Hookit Microfinishing Film Disc 268L, 30 Mic, Type D, 3 in x 7/8 in, Die 300M, 7000000297, 100/Case

100 × $0.51

3M 56038, Hookit Microfinishing Film Disc 268L, 30 Mic, Type D, 3 in x 7/8 in, Die 300M, 7000000297, 100/Case

100 × $0.51 -

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14 -

×

3M 34555, Cubitron II Net Sheet Roll, 240+, 80 mm x 10 m, 7100247339, 6 Rolls/Case

6 × $31.57

3M 34555, Cubitron II Net Sheet Roll, 240+, 80 mm x 10 m, 7100247339, 6 Rolls/Case

6 × $31.57 -

×

Dynabrade 93330 Carbide Burr, 1/4" Dia., SA-1 D/C Burr, Cylinder, 5/8" Flute L, 1/4" Shank

1 × $28.32

Dynabrade 93330 Carbide Burr, 1/4" Dia., SA-1 D/C Burr, Cylinder, 5/8" Flute L, 1/4" Shank

1 × $28.32 -

×

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

1500 × $0.73

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

1500 × $0.73 -

×

3M 01333, PSA Cloth Disc 348D, 60 X-weight, 3 in x NH, Die 300V, 7000118880

200 × $0.94

3M 01333, PSA Cloth Disc 348D, 60 X-weight, 3 in x NH, Die 300V, 7000118880

200 × $0.94 -

×

Insize 4209-4, LONG HANDLE TELESCOPING GAGE, 1-1/4 ~ 2-1/8", 6928640311567

1 × $16.55

Insize 4209-4, LONG HANDLE TELESCOPING GAGE, 1-1/4 ~ 2-1/8", 6928640311567

1 × $16.55 -

×

3M 26568, Cloth Belt 341D, 50 X-weight, 2 in x 48 in, Film-lok, Single-flex, 7010361745, 50 per case

50 × $3.85

3M 26568, Cloth Belt 341D, 50 X-weight, 2 in x 48 in, Film-lok, Single-flex, 7010361745, 50 per case

50 × $3.85 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00 -

×

3M 01875, Charge-Collection Solar Tape 3011, 2 mm x 1200 m, 7010312686

9 × $602.05

3M 01875, Charge-Collection Solar Tape 3011, 2 mm x 1200 m, 7010312686

9 × $602.05 -

×

Dynabrade 02696 Bearing

1 × $22.19

Dynabrade 02696 Bearing

1 × $22.19 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

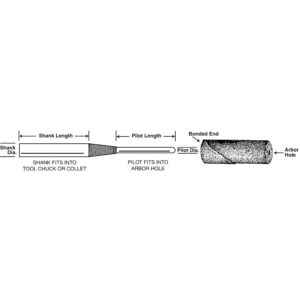

Standard Abrasives 710870, Cartridge Roll Mandrel, 1/8 in x 1/2 in x 1/4 in x 1-1/4 in x 2-1/4 in CM-7, 7000121794

5 × $4.71

Standard Abrasives 710870, Cartridge Roll Mandrel, 1/8 in x 1/2 in x 1/4 in x 1-1/4 in x 2-1/4 in CM-7, 7000121794

5 × $4.71 -

×

3M 26597, Cloth Belt 341D, P320 X-weight, 1 in x 42 in, Film-lok, Single-flex, 7010294511, 200 per case

200 × $2.14

3M 26597, Cloth Belt 341D, P320 X-weight, 1 in x 42 in, Film-lok, Single-flex, 7010294511, 200 per case

200 × $2.14 -

×

ACS Diamond Cloth Belt, CX1250 1" X 72" 125U

6 × $45.50

ACS Diamond Cloth Belt, CX1250 1" X 72" 125U

6 × $45.50 -

×

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25 -

×

3M 98282, VentureClad Insulation Jacketing Tape 1577CW-WME, White, 4 in x 50 yd, 7010376416

4 × $123.29

3M 98282, VentureClad Insulation Jacketing Tape 1577CW-WME, White, 4 in x 50 yd, 7010376416

4 × $123.29 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52 -

×

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95 -

×

3M 26710, PPS Series 2.0 Spray Cup System UV Kit, Standard (22 fl oz,

650 mL), 200 Micron Filter, 7100128902

1 × $142.27

3M 26710, PPS Series 2.0 Spray Cup System UV Kit, Standard (22 fl oz,

650 mL), 200 Micron Filter, 7100128902

1 × $142.27 -

×

ACS CX1250 Diamond Belts, 1/2" X 24" 45u

12 × $7.60

ACS CX1250 Diamond Belts, 1/2" X 24" 45u

12 × $7.60 -

×

Norton 69936606277 - 4" X 5/8" - 11, Carbon Steel Narrow Face Stringer Bead .0200" Knot Wire Wheel Brush, 5 per box

5 × $21.15

Norton 69936606277 - 4" X 5/8" - 11, Carbon Steel Narrow Face Stringer Bead .0200" Knot Wire Wheel Brush, 5 per box

5 × $21.15 -

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00 -

×

ACS Diamond Cloth Belt, CX1250 1/2" X 72" 125U

12 × $23.20

ACS Diamond Cloth Belt, CX1250 1/2" X 72" 125U

12 × $23.20 -

×

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67

3M 69367, Trizact Cloth Belt 237AA, A16 X-weight, 1/2 in x 24 in, Film-lok, Full-flex, 7010292266, 200 per case

$4.24

Factory Stock, 7-10 Day Leadtime

3M Trizact Cloth Belt 237AA uses proprietary microreplication technology by 3M where micron-graded aluminum oxide particles are formed into tiny pyramids of abrasive mineral and then coated on an X weight cloth backing. As these pyramids wear, fresh, sharp mineral is continually exposed to produce a consistent cut and a predictable, fine finish.