-

×

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95 -

×

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

600 × $0.95

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

600 × $0.95 -

×

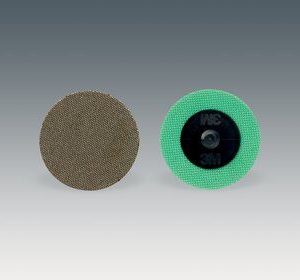

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

1500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

1500 × $0.60 -

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

500 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

500 × $4.14 -

×

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67 -

×

3M 15041, Scotch Electrical Shielding Tape 24, 1 in x 15 ft (25 mm x 4,6 m), 7000031348

10 × $38.32

3M 15041, Scotch Electrical Shielding Tape 24, 1 in x 15 ft (25 mm x 4,6 m), 7000031348

10 × $38.32 -

×

ACS Diamond Cloth Belt, CX1250 5/8" X 120" 125U

9 × $47.60

ACS Diamond Cloth Belt, CX1250 5/8" X 120" 125U

9 × $47.60 -

×

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38 -

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67 -

×

ACS Diamond Cloth Belt, CX1250 1/2" X 18" 250U

12 × $6.15

ACS Diamond Cloth Belt, CX1250 1/2" X 18" 250U

12 × $6.15 -

×

3M 01133, Hookit Red Finishing Film Abrasive Disc 260L, 6 in, Dust Free, P1500, 7010290267, 25 discs per carton

4 × $49.76

3M 01133, Hookit Red Finishing Film Abrasive Disc 260L, 6 in, Dust Free, P1500, 7010290267, 25 discs per carton

4 × $49.76 -

×

3M 21762, Stikit Cloth Disc Roll 341D, 60 X-weight, 6 in x NH, Die 600Z, 7000118780

400 × $169.03

3M 21762, Stikit Cloth Disc Roll 341D, 60 X-weight, 6 in x NH, Die 600Z, 7000118780

400 × $169.03 -

×

ACS Diamond Cloth Belt, CX1250 1/2" X 18" 125U

12 × $5.70

ACS Diamond Cloth Belt, CX1250 1/2" X 18" 125U

12 × $5.70 -

×

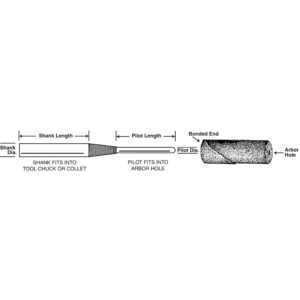

Standard Abrasives 716916, Cartridge RoII Mandrel, 6997818, 1/8 in x 3/4 in x 1/4 in x 6 in CM-XL, 7010368732

5 × $12.14

Standard Abrasives 716916, Cartridge RoII Mandrel, 6997818, 1/8 in x 3/4 in x 1/4 in x 6 in CM-XL, 7010368732

5 × $12.14 -

×

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98 -

×

3M 49938, Roloc Disc 361F, 80 YF-weight, TSM, 2 in, Die RS200PM, 7000119019

200 × $0.97

3M 49938, Roloc Disc 361F, 80 YF-weight, TSM, 2 in, Die RS200PM, 7000119019

200 × $0.97 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33 -

×

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93 -

×

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60 -

×

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

400 × $1.74

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

400 × $1.74 -

×

Standard Abrasives 714175, A/O Straight Cartridge Roll, 5/8 in x 1-1/2 in x 1/8 in 80, 7100103032

50 × $0.83

Standard Abrasives 714175, A/O Straight Cartridge Roll, 5/8 in x 1-1/2 in x 1/8 in 80, 7100103032

50 × $0.83 -

×

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33 -

×

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50 -

×

3M™ 85239, Roloc™ Flexible Diamond Disc 6234J, TR, 1-1/2 in x NH, M125 Micron, 7100100698

1 × $20.14

3M™ 85239, Roloc™ Flexible Diamond Disc 6234J, TR, 1-1/2 in x NH, M125 Micron, 7100100698

1 × $20.14 -

×

3M 17094, Versaflo Hood Assembly with Inner Shroud & Premium Head Suspension S-657, 7000002348, 1 EA/Case

1 × $99.90

3M 17094, Versaflo Hood Assembly with Inner Shroud & Premium Head Suspension S-657, 7000002348, 1 EA/Case

1 × $99.90 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 9u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 9u

12 × $7.60 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 69367, Trizact Cloth Belt 237AA, A16 X-weight, 1/2 in x 24 in, Film-lok, Full-flex, 7010292266, 200 per case

$4.24

Factory Stock, 7-10 Day Leadtime

3M Trizact Cloth Belt 237AA uses proprietary microreplication technology by 3M where micron-graded aluminum oxide particles are formed into tiny pyramids of abrasive mineral and then coated on an X weight cloth backing. As these pyramids wear, fresh, sharp mineral is continually exposed to produce a consistent cut and a predictable, fine finish.