-

×

Dynabrade 56180 5" Dia. Non-Vacuum Disc Pad, Hook-Face, Short Nap

1 × $24.26

Dynabrade 56180 5" Dia. Non-Vacuum Disc Pad, Hook-Face, Short Nap

1 × $24.26 -

×

Dynabrade 15029 Contact Arm Ass'y, 1" Dia. x 3/8" W, Tapered Rubber Wheel, No Platen/Offset Design

1 × $95.94

Dynabrade 15029 Contact Arm Ass'y, 1" Dia. x 3/8" W, Tapered Rubber Wheel, No Platen/Offset Design

1 × $95.94 -

×

3M 80485, Cloth Belt 777F, 80 YF-weight, 1/8 in x 24 in, Fabri-lok, Single-flex, 7000118436, 200 per case

200 × $2.20

3M 80485, Cloth Belt 777F, 80 YF-weight, 1/8 in x 24 in, Fabri-lok, Single-flex, 7000118436, 200 per case

200 × $2.20 -

×

3M 06535, Marine Adhesive Sealant 5200FC Fast Cure, PN06535, White, 1 oz Tube, 7010367674, 12/Case

12 × $10.71

3M 06535, Marine Adhesive Sealant 5200FC Fast Cure, PN06535, White, 1 oz Tube, 7010367674, 12/Case

12 × $10.71 -

×

Dynabrade 51629 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 1/8" Collet

1 × $573.77

Dynabrade 51629 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 1/8" Collet

1 × $573.77 -

×

3M 28848, Unitized Wheel Mandrel 28848, 1-5/8 in x 1/4 in x 3/4 in x 1/4 in, 7100082547

5 × $18.31

3M 28848, Unitized Wheel Mandrel 28848, 1-5/8 in x 1/4 in x 3/4 in x 1/4 in, 7100082547

5 × $18.31 -

×

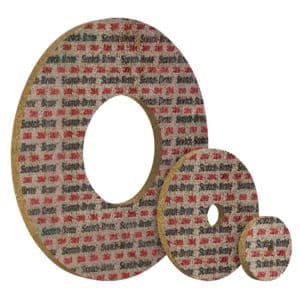

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70 -

×

3M 82279, Cubitron II Cut and Grind Wheel, T27, 4 1/2 in x 1/8 in x 7/8 in, 7100019243, 20 per case

20 × $10.85

3M 82279, Cubitron II Cut and Grind Wheel, T27, 4 1/2 in x 1/8 in x 7/8 in, 7100019243, 20 per case

20 × $10.85 -

×

3M 16580, Accuspray ONE Spray Gun System with Standard PPS, 7100099202

4 × $337.64

3M 16580, Accuspray ONE Spray Gun System with Standard PPS, 7100099202

4 × $337.64 -

×

Dynabrade 61201 RaptorVac Electric DrumVac Kit, Dual Operator, For Use With Tools

1 × $2,477.83

Dynabrade 61201 RaptorVac Electric DrumVac Kit, Dual Operator, For Use With Tools

1 × $2,477.83 -

×

Dynabrade 14200 Dynangle Abrasive Belt Tool

1 × $1,219.27

Dynabrade 14200 Dynangle Abrasive Belt Tool

1 × $1,219.27 -

×

Dynabrade 51474 5"-8" Dia. Right-Angle Wet Rotary Sander, Basic, .7 HP, 0-2,000 RPM, 5/8"-11 Spindle Thread

1 × $1,495.66

Dynabrade 51474 5"-8" Dia. Right-Angle Wet Rotary Sander, Basic, .7 HP, 0-2,000 RPM, 5/8"-11 Spindle Thread

1 × $1,495.66 -

×

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38 -

×

3M 05535, Cubitron II Cloth Belt 981F, 4 x 132 in, 40+, YF-weight, Film-lok, 7100164954, 25 per case

25 × $24.31

3M 05535, Cubitron II Cloth Belt 981F, 4 x 132 in, 40+, YF-weight, Film-lok, 7100164954, 25 per case

25 × $24.31 -

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,493.91

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,493.91 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $10.89

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $10.89 -

×

Standard Abrasives 711599, A/O Straight Cartridge Roll, 1/4 in x 1 in x 1/8 in 80, 7100080016

100 × $0.33

Standard Abrasives 711599, A/O Straight Cartridge Roll, 1/4 in x 1 in x 1/8 in 80, 7100080016

100 × $0.33 -

×

Dynabrade 51623 .1 hp Straight-Line Extension Pencil Grinder, Central Vacuum, 1/8" Collet

1 × $604.39

Dynabrade 51623 .1 hp Straight-Line Extension Pencil Grinder, Central Vacuum, 1/8" Collet

1 × $604.39 -

×

Dynabrade 48335 .4 hp 7 Degree Offset Die Grinder, Rear Exhaust, 25,000 RPM, 1/4" Collet

1 × $463.57

Dynabrade 48335 .4 hp 7 Degree Offset Die Grinder, Rear Exhaust, 25,000 RPM, 1/4" Collet

1 × $463.57 -

×

Dynabrade 90405 1/8" W x 24" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $0.79

Dynabrade 90405 1/8" W x 24" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $0.79 -

×

Dynabrade 82577 1/2" W x 24" L 80 Grit Ceramic DynaCut Belt, 50/pack

50 × $3.19

Dynabrade 82577 1/2" W x 24" L 80 Grit Ceramic DynaCut Belt, 50/pack

50 × $3.19 -

×

3M 26130, PPS Series 2.0 Adapter, Type S35, 16 mm Female, 1.5 mm

Thread Stretched, 7100135926

1 × $25.96

3M 26130, PPS Series 2.0 Adapter, Type S35, 16 mm Female, 1.5 mm

Thread Stretched, 7100135926

1 × $25.96 -

×

Dynabrade 50080 Collet, M8 x 1.0 Female Thread, 1/4" Capacity

1 × $74.35

Dynabrade 50080 Collet, M8 x 1.0 Female Thread, 1/4" Capacity

1 × $74.35 -

×

3M 33443, Cubitron II File Belt, 36+, 1/2 in x 18 in (12.7 mm x 457.2 mm), 7100033184, 10 belts per carton, 5 cartons per case

50 × $33.94

3M 33443, Cubitron II File Belt, 36+, 1/2 in x 18 in (12.7 mm x 457.2 mm), 7100033184, 10 belts per carton, 5 cartons per case

50 × $33.94 -

×

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95

3M 01328, PSA Cloth Disc 348D, P180 X-weight, 3 in x NH, Die 300V, 7000045068

200 × $0.95

3M 66947, Trizact Cloth Belt 237AA, A100 X-weight, 3-1/2 in x 15-1/2 in, Film-lok, Full-flex, 7000028336, 50 per case

$11.59

Factory Stock, 7-10 Day Leadtime

3M Trizact Cloth Belt 237AA uses proprietary microreplication technology by 3M where micron-graded aluminum oxide particles are formed into tiny pyramids of abrasive mineral and then coated on an X weight cloth backing. As these pyramids wear, fresh, sharp mineral is continually exposed to produce a consistent cut and a predictable, fine finish.