-

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,583.72

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,583.72 -

×

Dynabrade 13505 Dynastraight Finishing Tool, 1 HP, Rear Exhaust, 3,400 RPM, 5/8"-11 Arbor

1 × $948.13

Dynabrade 13505 Dynastraight Finishing Tool, 1 HP, Rear Exhaust, 3,400 RPM, 5/8"-11 Arbor

1 × $948.13 -

×

Dynabrade 92102 3" W x 10-11/16" L 80 Grit A/Z DynaCut Belt, 10/pack

10 × $3.88

Dynabrade 92102 3" W x 10-11/16" L 80 Grit A/Z DynaCut Belt, 10/pack

10 × $3.88 -

×

Dynabrade 64354 26" x 36" (660 mm W x 914 mm L) Metal Capture Downdraft Station, 460 V (AC)

1 × $17,693.66

Dynabrade 64354 26" x 36" (660 mm W x 914 mm L) Metal Capture Downdraft Station, 460 V (AC)

1 × $17,693.66 -

×

Dynabrade 95600 Tune-Up Kit for .5 hp Motor

1 × $130.26

Dynabrade 95600 Tune-Up Kit for .5 hp Motor

1 × $130.26 -

×

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

25 × $1.84

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

25 × $1.84 -

×

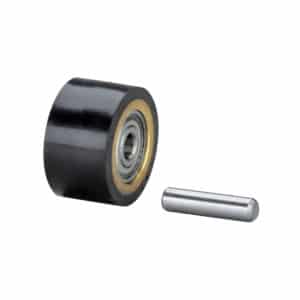

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $34.87

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $34.87 -

×

3M 49941, Roloc Disc 361F, 80 YF-weight, TSM, 3 in, Die RS300VM, 7000148151

200 × $1.33

3M 49941, Roloc Disc 361F, 80 YF-weight, TSM, 3 in, Die RS300VM, 7000148151

200 × $1.33 -

×

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

200 × $0.97

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

200 × $0.97 -

×

Dynabrade 78645 1/2" Dia. x 1-1/2" W x 1/8" Center Hole, Z/A, 60 Grit, 100/pack

100 × $1.02

Dynabrade 78645 1/2" Dia. x 1-1/2" W x 1/8" Center Hole, Z/A, 60 Grit, 100/pack

100 × $1.02 -

×

Dynabrade 13512 Dynastraight 6" (152 mm) Extension Finishing Tool, 1 HP, Rear Exhaust, 3,400 RPM, 1/2" (13 mm) Dia. Arbor

1 × $1,140.55

Dynabrade 13512 Dynastraight 6" (152 mm) Extension Finishing Tool, 1 HP, Rear Exhaust, 3,400 RPM, 1/2" (13 mm) Dia. Arbor

1 × $1,140.55 -

×

Dynabrade 78006 1/2" W x 12" L Coarse Non-Woven DynaBrite Belts, 10/pack

10 × $4.69

Dynabrade 78006 1/2" W x 12" L Coarse Non-Woven DynaBrite Belts, 10/pack

10 × $4.69 -

×

Dynabrade 52934 1/4" Drill, .4 HP, Rear Exhaust, 3,600 RPM

1 × $679.61

Dynabrade 52934 1/4" Drill, .4 HP, Rear Exhaust, 3,600 RPM

1 × $679.61 -

×

Dynabrade 56106 5" Dia. Non-Vacuum Disc Pad, Vinyl-Face

1 × $23.43

Dynabrade 56106 5" Dia. Non-Vacuum Disc Pad, Vinyl-Face

1 × $23.43 -

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $27,619.39

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $27,619.39 -

×

Dynabrade 90370 3/4" W x 34" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $2.38

Dynabrade 90370 3/4" W x 34" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $2.38 -

×

Dynabrade 90924 3" Dia. x 40 Grit A/Z DynaCut Locking-Type (TR), Flap Disc, 10/pack

10 × $4.30

Dynabrade 90924 3" Dia. x 40 Grit A/Z DynaCut Locking-Type (TR), Flap Disc, 10/pack

10 × $4.30 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $24.56

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $24.56 -

×

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39 -

×

Dynabrade 13310 Mini-Dynisher Finishing Tool Versatility Kit, .4 HP, Rear Exhaust, 3,200 RPM, 5/8" Arbor

1 × $1,140.55

Dynabrade 13310 Mini-Dynisher Finishing Tool Versatility Kit, .4 HP, Rear Exhaust, 3,200 RPM, 5/8" Arbor

1 × $1,140.55 -

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 54139, Scotch-Brite, Roloc AL Surface Conditioning Disc TR, 3 in x NH A MED, 7100075556, 100 per case

This item has been Discontinued. Please see 3M suggested replacement item 7100264196.

The Scotch-Brite Roloc AL Surface Conditioning Disc cleans, finishes, blends and deburrs a variety of substrates, including ferrous and non-ferrous metals. It strikes the perfect balance between strength and softness. Use this disc to rid your workpiece of contaminants without severely altering part geometry.