-

×

Dynabrade 56106 5" Dia. Non-Vacuum Disc Pad, Vinyl-Face

2 × $23.43

Dynabrade 56106 5" Dia. Non-Vacuum Disc Pad, Vinyl-Face

2 × $23.43 -

×

Dynabrade 52204 .4 hp 7 Degree Offset Die Grinder, Front Exhaust, 25,000 RPM, 1/4" Collet

1 × $437.33

Dynabrade 52204 .4 hp 7 Degree Offset Die Grinder, Front Exhaust, 25,000 RPM, 1/4" Collet

1 × $437.33 -

×

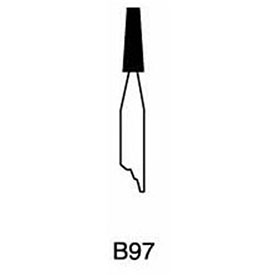

Dynabrade 78742 1/8" x 3/8"-B97 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $2.03

Dynabrade 78742 1/8" x 3/8"-B97 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $2.03 -

×

Dynabrade 52538 3" (76 mm) Dia. Right Angle Vacuum Cut-Off Wheel Tool

1 × $910.52

Dynabrade 52538 3" (76 mm) Dia. Right Angle Vacuum Cut-Off Wheel Tool

1 × $910.52 -

×

Dynabrade 54363 .7 hp Extended Right Angle Die Grinder, Rear Exhaust, 18,000 RPM, 1/4" Collet

1 × $993.60

Dynabrade 54363 .7 hp Extended Right Angle Die Grinder, Rear Exhaust, 18,000 RPM, 1/4" Collet

1 × $993.60 -

×

Dynabrade 95600 Tune-Up Kit for .5 hp Motor

1 × $130.26

Dynabrade 95600 Tune-Up Kit for .5 hp Motor

1 × $130.26 -

×

Dynabrade 52672 1 hp Straight-Line 6" (152 mm) Extension Die Grinder, Rear Exhaust, 3,400 RPM, 1/4" Collet

1 × $1,017.23

Dynabrade 52672 1 hp Straight-Line 6" (152 mm) Extension Die Grinder, Rear Exhaust, 3,400 RPM, 1/4" Collet

1 × $1,017.23 -

×

Dynabrade 25230 Gear Set- 1.176: 1 Ratio, 1.3Hp

1 × $220.09

Dynabrade 25230 Gear Set- 1.176: 1 Ratio, 1.3Hp

1 × $220.09 -

×

Dynabrade 56027 Muffler Insert

1 × $1.93

Dynabrade 56027 Muffler Insert

1 × $1.93 -

×

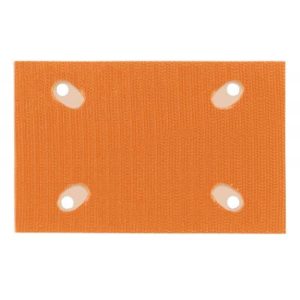

Dynabrade 56316 3" x 4-1/4" Vacuum Dynabug II Disc Pad, Hook-Face, Short Nap

1 × $31.98

Dynabrade 56316 3" x 4-1/4" Vacuum Dynabug II Disc Pad, Hook-Face, Short Nap

1 × $31.98 -

×

Dynabrade 15401 Dynafile III Abrasive Belt Tool for 20-1/2" Belts

1 × $806.43

Dynabrade 15401 Dynafile III Abrasive Belt Tool for 20-1/2" Belts

1 × $806.43 -

×

Dynabrade 98580 Motor Tune-Up Kit for National Detroit Sander Models

1 × $123.86

Dynabrade 98580 Motor Tune-Up Kit for National Detroit Sander Models

1 × $123.86 -

×

Dynabrade 39200 2" Type C, Roto Peen Flaps

1 × $65.85

Dynabrade 39200 2" Type C, Roto Peen Flaps

1 × $65.85 -

×

Dynabrade X51 5" (127 mm) Dia. Non-Vacuum Dynorbital Extreme Random Orbital Sander, .3 HP, 12,000 RPM, 3/16" Orbit, PSA

1 × $213.35

Dynabrade X51 5" (127 mm) Dia. Non-Vacuum Dynorbital Extreme Random Orbital Sander, .3 HP, 12,000 RPM, 3/16" Orbit, PSA

1 × $213.35 -

×

Dynabrade 51347 3" (51 mm) Dia. Locking-Type Disc Pad, Medium Density, 3/8"-24 Thread

1 × $15.99

Dynabrade 51347 3" (51 mm) Dia. Locking-Type Disc Pad, Medium Density, 3/8"-24 Thread

1 × $15.99 -

×

Dynabrade 01111 Drive Wheel

1 × $36.49

Dynabrade 01111 Drive Wheel

1 × $36.49 -

×

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95

3M 54137, Scotch-Brite, Roloc AL Surface Conditioning Disc TR, 2 in x NH A CRS, 7100075554, 200 per case

$1.39

Discontinued, 3M Suggested Replacement-

| 7100264090 |

The Scotch-Brite Roloc AL Surface Conditioning Disc cleans, finishes, blends and deburrs a variety of substrates, including ferrous and non-ferrous metals. It strikes the perfect balance between strength and softness. Use this disc to rid your workpiece of contaminants without severely altering part geometry.

Effectively Remove Burrs and Contaminants without Damaging Base Material

Scotch-Brite products can help make your tough jobs easier. The Scotch-Brite Roloc AL Surface Conditioning Disc, specifically, helps achieve burr-free, paintable finishes in fewer steps without changing the geometry of the work piece. It excels on soft substrates and applications where loading is the cause of the end of the abrasive life.

Aluminum Oxide Mineral Cuts Fast and Sharp

Aluminum oxide mineral is interspersed in the discs open web. Aluminum oxide is a popular choice among industrial professionals given its durability and sharp cut. Moreover, aluminum oxide is known for being friable, meaning it fragments under heat and pressure in order to self renew. Friability keeps the mineral cutting sharp. While all discs use aluminum oxide, we offer Scotch-Brite Roloc AL Surface Conditioning Disc in three grades: very fine (VFN), medium (MED) and coarse (CRS). In this way, operators can choose a grade thats tailored to their substrate and desired finish.

Roloc System for Easy Power Tool Attachment

We included a 3M Roloc quick-change attachment on this disc so operators could easily swap between discs when there are multiple grades in a sequence. It also makes for quick power tool attachment, helping enhance productivity and throughput. To attach the disc, operators simply need to attach it to a Roloc backup pad (sold separately). Subsequently, the backup pad attaches to the power tool. The attachment options include TS, TSM and TR some being metal and some being plastic. Operators should choose the right attachment for their tools.

The Scotch-Brite Advantage

Scotch-Brite products incorporate mineral into non-woven nylon fibers. Breakthrough fiber coating technology allows Scotch-Brite abrasive products to cut faster and produce a more consistent scratch. The open-web material is load resistant and keeps the abrasive minerals cutting at high performance by limiting clogging of the nylon fibers. As the nylon fibers break down gradually during grinding, they expose fresh mineral, so you get that consistent sharp cut part after part.