-

×

Standard Abrasives 713066, PSA A/O Disc, 8 in x NH, 60, 7010370082

10 × $2.48

Standard Abrasives 713066, PSA A/O Disc, 8 in x NH, 60, 7010370082

10 × $2.48 -

×

Dynabrade 52434 3" (76 mm) Dia. Straight-Line Cut-Off Wheel Tool, Front Exhaust, .5 HP, 20,000 RPM, 3/8"-24 Spindle

1 × $432.09

Dynabrade 52434 3" (76 mm) Dia. Straight-Line Cut-Off Wheel Tool, Front Exhaust, .5 HP, 20,000 RPM, 3/8"-24 Spindle

1 × $432.09 -

×

Dynabrade 78586 1/4" Dia. x 1-1/2" W x 1/8" Center Hole, 180 Grit, 100/pack

100 × $0.54

Dynabrade 78586 1/4" Dia. x 1-1/2" W x 1/8" Center Hole, 180 Grit, 100/pack

100 × $0.54 -

×

Dynabrade 25249 Tip Valve

1 × $8.00

Dynabrade 25249 Tip Valve

1 × $8.00 -

×

Dynabrade 52083 Base

1 × $62.39

Dynabrade 52083 Base

1 × $62.39 -

×

Dynabrade 69329 Housing Replacement for Model No. 69104

1 × $82.72

Dynabrade 69329 Housing Replacement for Model No. 69104

1 × $82.72 -

×

Dynabrade 51703 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 1/8" Collet

1 × $531.79

Dynabrade 51703 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 1/8" Collet

1 × $531.79 -

×

Dynabrade 58070 4" W x 4-1/2" L Dynabug "Model T" Orbital Sander, Self-Generated Vacuum, 20,000 RPM, 3/32" Orbit, PSA

1 × $295.60

Dynabrade 58070 4" W x 4-1/2" L Dynabug "Model T" Orbital Sander, Self-Generated Vacuum, 20,000 RPM, 3/32" Orbit, PSA

1 × $295.60 -

×

Dynabrade 54744 4" (102 mm) Dia. Right Angle Type 1 Cut-Off Tool, Steel Housing, .7 HP, 13,500 RPM, 3/8"-24 Spindle

1 × $969.99

Dynabrade 54744 4" (102 mm) Dia. Right Angle Type 1 Cut-Off Tool, Steel Housing, .7 HP, 13,500 RPM, 3/8"-24 Spindle

1 × $969.99 -

×

Dynabrade 94909 Screw

1 × $7.16

Dynabrade 94909 Screw

1 × $7.16 -

×

Dynabrade 93348 Carbide Burr, 1/8" Dia., SM-42 D/C Burr, 14 Degree Cone, 7/16" Flute L, 1/8" Shank

1 × $15.84

Dynabrade 93348 Carbide Burr, 1/8" Dia., SM-42 D/C Burr, 14 Degree Cone, 7/16" Flute L, 1/8" Shank

1 × $15.84 -

×

Dynabrade RB2 - 8" Right Angle Buffer/Polisher

1 × $465.40

Dynabrade RB2 - 8" Right Angle Buffer/Polisher

1 × $465.40 -

×

Dynabrade 31919 - 20' Long D-Block Vac Hose Assembly

1 × $202.40

Dynabrade 31919 - 20' Long D-Block Vac Hose Assembly

1 × $202.40 -

×

Dynabrade 78473 2-1/2" Dia. x 3/4", 8-32 Female Center Thread, A/O, 60 Grit, 8-Ply J-DynaCut Cross Pad, 100/pack

100 × $2.35

Dynabrade 78473 2-1/2" Dia. x 3/4", 8-32 Female Center Thread, A/O, 60 Grit, 8-Ply J-DynaCut Cross Pad, 100/pack

100 × $2.35 -

×

Dynabrade 40360 Housing, Dynafile II

1 × $121.55

Dynabrade 40360 Housing, Dynafile II

1 × $121.55 -

×

Dynabrade 93394 4" Dia. x 1/2" Center Hole, 150 Grit, A/O,. Arbor-Mount Sanding Star, 10/pack

10 × $7.57

Dynabrade 93394 4" Dia. x 1/2" Center Hole, 150 Grit, A/O,. Arbor-Mount Sanding Star, 10/pack

10 × $7.57 -

×

3M DP16, Scotch-Brite Driving Pad, 16 in , White, 7000126477

5 × $10.14

3M DP16, Scotch-Brite Driving Pad, 16 in , White, 7000126477

5 × $10.14 -

×

Dynabrade 92283 Bolt, Dynazip Hub

1 × $17.43

Dynabrade 92283 Bolt, Dynazip Hub

1 × $17.43 -

×

Dynabrade 25383 Housing Ass'y for Model 54769

1 × $131.31

Dynabrade 25383 Housing Ass'y for Model 54769

1 × $131.31 -

×

Dynabrade 10967 Bearing

1 × $8.99

Dynabrade 10967 Bearing

1 × $8.99 -

×

Dynabrade 25264 Wick

1 × $12.98

Dynabrade 25264 Wick

1 × $12.98 -

×

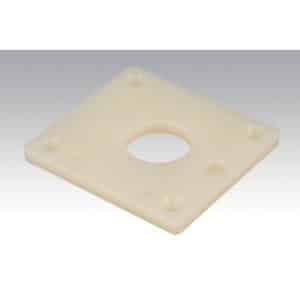

Dynabrade 52081 Cover Plate

1 × $11.37

Dynabrade 52081 Cover Plate

1 × $11.37 -

×

Dynabrade 33630 ND6010, Pad Shoe

1 × $88.13

Dynabrade 33630 ND6010, Pad Shoe

1 × $88.13 -

×

Dynabrade 96681 Tune-Up Kit

1 × $169.93

Dynabrade 96681 Tune-Up Kit

1 × $169.93 -

×

Dynabrade 01489 Rear Exhaust Cover

1 × $60.01

Dynabrade 01489 Rear Exhaust Cover

1 × $60.01 -

×

Dynabrade 52850 0.1 hp Straight-Line Variable Speed Pencil Grinder, Rear Exhaust, 35-60,000 RPM, 1/8" Collet

1 × $662.99

Dynabrade 52850 0.1 hp Straight-Line Variable Speed Pencil Grinder, Rear Exhaust, 35-60,000 RPM, 1/8" Collet

1 × $662.99 -

×

Dynabrade 94877 Female Straight Connector (for 5/16" I.D. Hose)

1 × $4.00

Dynabrade 94877 Female Straight Connector (for 5/16" I.D. Hose)

1 × $4.00 -

×

Dynabrade 53668 Carrier

1 × $202.34

Dynabrade 53668 Carrier

1 × $202.34 -

×

Dynabrade 02152 Housing for Model 52222

1 × $102.11

Dynabrade 02152 Housing for Model 52222

1 × $102.11 -

×

Dynabrade 96419 Bearing Press Tool

1 × $49.25

Dynabrade 96419 Bearing Press Tool

1 × $49.25 -

×

Dynabrade 78782 DynaCut Wire Cup Brush 3" Dia. x .014 5/8-11 UNC AH Steel

1 × $21.85

Dynabrade 78782 DynaCut Wire Cup Brush 3" Dia. x .014 5/8-11 UNC AH Steel

1 × $21.85 -

×

Dynabrade 78113 2" Dia. x 80 Grit Premium Ceramic Non-Vacuum DynaCut Locking-Type Disc, 25/pack

25 × $1.66

Dynabrade 78113 2" Dia. x 80 Grit Premium Ceramic Non-Vacuum DynaCut Locking-Type Disc, 25/pack

25 × $1.66 -

×

Dynabrade 18813 Stop Rod

1 × $3.98

Dynabrade 18813 Stop Rod

1 × $3.98 -

×

Dynabrade 51402 3" Dia. 7 Degree Offset Rotary Buffer, .4 hp, 3,600 RPM, Rear Exhaust, 3/8"-24 Spindle Thread

1 × $791.57

Dynabrade 51402 3" Dia. 7 Degree Offset Rotary Buffer, .4 hp, 3,600 RPM, Rear Exhaust, 3/8"-24 Spindle Thread

1 × $791.57 -

×

Dynabrade 01476 Air Motor Cylinder

1 × $137.76

Dynabrade 01476 Air Motor Cylinder

1 × $137.76 -

×

Dynabrade 25400 Housing Assembly for 54787

1 × $247.61

Dynabrade 25400 Housing Assembly for 54787

1 × $247.61 -

×

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50

3M 57148, Cloth Belt 970DZ, P150 Y-weight, 8 in x 150 in, Film-lok, Single-flex, 7010308249, 10 per case

$72.40

Factory Stock, 7-10 Day Leadtime

3M Cloth Belt 970DZ is a best-in-class heavy cloth belt constructed of?high-performing 3M?Ceramic Abrasive Grain and designed for medium grade operations on wide belt or edge sanders. Applications include dimensioning and stock removal. The exceptionally fast cut and long life of ceramic grain make it ideal for high production environments.