-

×

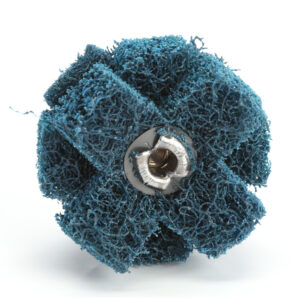

Standard Abrasives 840458, Quick Change Buff and Blend HS Disc, Medium, TR, Blue, 3 in, Die Q300V, 7100074872, 25/case

50 × $3.71

Standard Abrasives 840458, Quick Change Buff and Blend HS Disc, Medium, TR, Blue, 3 in, Die Q300V, 7100074872, 25/case

50 × $3.71 -

×

3M 60230, Scotch-Brite Hookit Cut and Polish Disc, CP-HA, A/O Medium, 5 in x NH, 7000121099

40 × $4.25

3M 60230, Scotch-Brite Hookit Cut and Polish Disc, CP-HA, A/O Medium, 5 in x NH, 7000121099

40 × $4.25 -

×

3M 54142, Scotch-Brite, Roloc AL Surface Conditioning Disc TSM, 2 in x NH A MED, 7100075559, 200 per case

200 × $1.39

3M 54142, Scotch-Brite, Roloc AL Surface Conditioning Disc TSM, 2 in x NH A MED, 7100075559, 200 per case

200 × $1.39 -

×

3M 25770, Scotch-Brite Roloc Surface Conditioning Disc, TSM, 2 in x NH A VFN, 7000120996, 200/case

50 × $1.35

3M 25770, Scotch-Brite Roloc Surface Conditioning Disc, TSM, 2 in x NH A VFN, 7000120996, 200/case

50 × $1.35 -

×

3M 86802, Cubitron II Stikit Film Disc 775L, 80+, 5 in x NH, Linered w/Tab, Die 500X, 7100048736, 250 per case

250 × $1.11

3M 86802, Cubitron II Stikit Film Disc 775L, 80+, 5 in x NH, Linered w/Tab, Die 500X, 7100048736, 250 per case

250 × $1.11 -

×

3M 97251, FuII Tapered Cartridge RoII 341D, 3/8 in x 1-1/2 in x 1/8 in, P120 X-weight, 7010327463

100 × $1.11

3M 97251, FuII Tapered Cartridge RoII 341D, 3/8 in x 1-1/2 in x 1/8 in, P120 X-weight, 7010327463

100 × $1.11 -

×

Standard Abrasives 725005, Buff and Blend Cross Buff HS, A/O Medium, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046826

100 × $6.37

Standard Abrasives 725005, Buff and Blend Cross Buff HS, A/O Medium, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046826

100 × $6.37 -

×

3M 66783, Cubitron II Roloc Fibre Disc 982C, 60+, TR, Red, 2 in, Die R200P, 7000118431, 200 per case

200 × $2.00

3M 66783, Cubitron II Roloc Fibre Disc 982C, 60+, TR, Red, 2 in, Die R200P, 7000118431, 200 per case

200 × $2.00 -

×

3M 54256, Cubitron II Roloc Durable Edge Disc 947A, 80+, X-weight, TR, Maroon, 2 in, Die R200P, 7100076925, 200 per case

800 × $1.33

3M 54256, Cubitron II Roloc Durable Edge Disc 947A, 80+, X-weight, TR, Maroon, 2 in, Die R200P, 7100076925, 200 per case

800 × $1.33 -

×

3M 18081, Scotch-Brite Roloc SE Surface Conditioning Disc, SE-DR, A/O Coarse, 18081, 2714483, TR, 2 in, 7000046111, 200 per case

200 × $1.63

3M 18081, Scotch-Brite Roloc SE Surface Conditioning Disc, SE-DR, A/O Coarse, 18081, 2714483, TR, 2 in, 7000046111, 200 per case

200 × $1.63 -

×

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

600 × $1.25

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

600 × $1.25 -

×

3M 05058, Cubitron II Hookit Clean Sanding Film Disc 775L, 400+, 5 in, Die 500LG, 7100145404, 250 per case

250 × $1.12

3M 05058, Cubitron II Hookit Clean Sanding Film Disc 775L, 400+, 5 in, Die 500LG, 7100145404, 250 per case

250 × $1.12 -

×

3M 05220, Marine Adhesive Sealant 5200FC Fast Cure, White, 3 oz Tube, 7000120490, 6/Case

6 × $17.72

3M 05220, Marine Adhesive Sealant 5200FC Fast Cure, White, 3 oz Tube, 7000120490, 6/Case

6 × $17.72 -

×

3M 02115, Paper Sheet 346U, 80 D-weight, 9 in x 11 in, 7000120220

1000 × $0.94

3M 02115, Paper Sheet 346U, 80 D-weight, 9 in x 11 in, 7000120220

1000 × $0.94 -

×

3M 77198, Scotch Brite Roloc Deburr & Finish PRO Unitized Wheel, DP-UR, 8C Coarse+, TR, 2 in x 1/4 in x NH, 7100109131

60 × $7.14

3M 77198, Scotch Brite Roloc Deburr & Finish PRO Unitized Wheel, DP-UR, 8C Coarse+, TR, 2 in x 1/4 in x NH, 7100109131

60 × $7.14 -

×

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03 -

×

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52

3M 16164, 3M PTFE Film Tape 5480, Gray, 1/2 in x 36 yd, 3.7 mil, 18 rolls percase, Boxed, 7000125252

$75.72

Factory Stock, 7-10 Day Leadtime

3M PTFE Skived Film Tape 5480 uses a skived, polytetrafluoroethylene (PTFE), conformable film backing. This tape offers an extremely low coefficient of friction which, in combination with a pressure sensitive silicone adhesive, creates a smooth, non-stick surface over a variety of substrates to assist in the movement of web materials in many types of roll-wrap applications.