-

×

3M 55037, Cubitron II Cloth Belt 984F, 60+ YF-weight, 6 in x 48 in, Film-lok, Single-flex, 7010308910, 20 per case

20 × $34.17

3M 55037, Cubitron II Cloth Belt 984F, 60+ YF-weight, 6 in x 48 in, Film-lok, Single-flex, 7010308910, 20 per case

20 × $34.17 -

×

ACS Diamond Cloth Belt, CX1250 3" X 30" 45U

2 × $57.10

ACS Diamond Cloth Belt, CX1250 3" X 30" 45U

2 × $57.10 -

×

3M 62795, Polyurethane Adhesive Sealant 550FC Fast Cure, Black, 310 mL Cartridge, 7100001803, 12/Case

12 × $11.11

3M 62795, Polyurethane Adhesive Sealant 550FC Fast Cure, Black, 310 mL Cartridge, 7100001803, 12/Case

12 × $11.11 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

3M 20922, PSA Cloth Disc 348D, 60 X-weight, 1-1/2 in x NH, Die 150S, 7010326528.

500 × $0.48

3M 20922, PSA Cloth Disc 348D, 60 X-weight, 1-1/2 in x NH, Die 150S, 7010326528.

500 × $0.48 -

×

3M 69042, Scotch-Weld EPX Mixing Nozzle, Helical Orange, 490 mL, High Throughput, 7100015959

36 × $4.53

3M 69042, Scotch-Weld EPX Mixing Nozzle, Helical Orange, 490 mL, High Throughput, 7100015959

36 × $4.53 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75 -

×

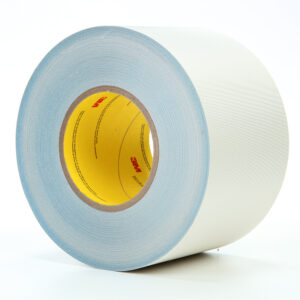

3M 85652, Thermosetable Glass Cloth Tape 3650, White, 4 in x 60 yd, 8.3 mil, 7010373472

8 × $375.45

3M 85652, Thermosetable Glass Cloth Tape 3650, White, 4 in x 60 yd, 8.3 mil, 7010373472

8 × $375.45 -

×

3M 29833, Sanding Screen, 120 Grit, 18 in x NH, 7100160843

12 × $6.55

3M 29833, Sanding Screen, 120 Grit, 18 in x NH, 7100160843

12 × $6.55 -

×

3M 45194, Disc Pad Face Plate 45194, 7 in Soft White, 7000120522

10 × $29.99

3M 45194, Disc Pad Face Plate 45194, 7 in Soft White, 7000120522

10 × $29.99 -

×

3M 19568, Cloth Belt 777F, 50 YF-weight, 3/4 in x 18 in, Fabri-lok, Full-flex, 7000148229, 200 per case

200 × $2.70

3M 19568, Cloth Belt 777F, 50 YF-weight, 3/4 in x 18 in, Fabri-lok, Full-flex, 7000148229, 200 per case

200 × $2.70 -

×

3M 08025, Adhesive Sealant 740 UV, Black, 600 mL Sausage Pack, 7100057385, 12/Case

12 × $21.89

3M 08025, Adhesive Sealant 740 UV, Black, 600 mL Sausage Pack, 7100057385, 12/Case

12 × $21.89 -

×

3M 14276 Scotch-Brite Surface Conditioning Belt, 1/4 in x 18 in, A MED, 7000120687

40 × $3.30

3M 14276 Scotch-Brite Surface Conditioning Belt, 1/4 in x 18 in, A MED, 7000120687

40 × $3.30 -

×

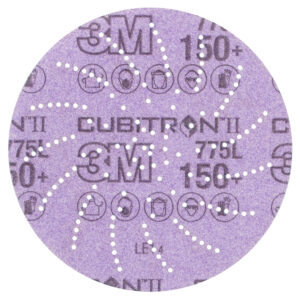

3M 64258, Cubitron II Hookit Clean Sanding Film Disc 775L, 150+, 5 in, Die 500LG, 7100064175, 250 per case

250 × $1.12

3M 64258, Cubitron II Hookit Clean Sanding Film Disc 775L, 150+, 5 in, Die 500LG, 7100064175, 250 per case

250 × $1.12 -

×

3M 89654, Fibre Disc 787C, 120+, 4-1/2 in x 7/8 in, Die 450E, 7100099280

100 × $3.21

3M 89654, Fibre Disc 787C, 120+, 4-1/2 in x 7/8 in, Die 450E, 7100099280

100 × $3.21 -

×

3M 18730, Scotch-Brite Roloc Bristle Disc, RD-ZB, 50, TR, Green, 2 in x 5/8 in, Tapered, 7000000742

40 × $9.65

3M 18730, Scotch-Brite Roloc Bristle Disc, RD-ZB, 50, TR, Green, 2 in x 5/8 in, Tapered, 7000000742

40 × $9.65 -

×

3M 22398, Roloc Disc 361F, 36 YF-weight, TR, 2 in, Die R200P, 7000000371

200 × $1.11

3M 22398, Roloc Disc 361F, 36 YF-weight, TR, 2 in, Die R200P, 7000000371

200 × $1.11 -

×

3M 01004, Scotch-Weld EPX Mixing Nozzle, Helical White, 48.5 mL and 50 mL, 7100148766

72 × $3.14

3M 01004, Scotch-Weld EPX Mixing Nozzle, Helical White, 48.5 mL and 50 mL, 7100148766

72 × $3.14 -

×

3M 14345, Marine Adhesive Sealant 4000 UV, Black, 3 oz Tube, 7010367954, 6/Case

6 × $15.34

3M 14345, Marine Adhesive Sealant 4000 UV, Black, 3 oz Tube, 7010367954, 6/Case

6 × $15.34

3M 05095, Acryl Putty, White, 14.5 oz, 7000045479

$29.92

Factory Stock, 7-10 Day Leadtime

3M Acryl Putty restores smooth surfaces by filling small pinholes, scratches, stone chips and other minor blemishes in automotive and marine finishes. Our acrylic putty offers easy sanding, smooth spreading and low shrinkage.

Patch Minor Imperfections

3M™ Acryl Putty fills minor surface blemishes in cars, trucks, vans, boats and other vehicles. Our acrylic glazing putty offers excellent workability with easy and smooth spreadability that effectively conceals pinholes, sand scratches and other spot repairs. Once the putty fully cures, you’ll appreciate its low rate of shrinkage and excellent adhesion to the surface.

Better Feathering Means Less Work

Our spot putty offers high quality feathering properties, meaning it is easy to smooth out the edges to blend with the surrounding surface. Good feathering will produce more satisfactory results and reduce sanding.

Choose the Putty that’s Right for You

3M™ Acryl Putty comes in multiple formulas offering different rates of drying, working time and sanding time. Use these numbers as estimates only. Actual drying, work and sanding times will vary depending on environmental conditions.

Formulas Include:

- 3M™ Acryl-White Putty is a slow drying formula with a 2.5 minute work time and 25 minute sanding time

- 3M™ Acryl-Red Putty is a medium drying formula with 2 minute work time and 20 minute sanding time

- 3M™ Acryl-Green Putty is a fast drying formula with a 1.5 minute work time and 15 minute sanding time

Directions for Use:

- Do not apply when ambient temperatures are below 55ºF or above 110ºF. Use in a well ventilated area away from sparks or open flame. (Do not apply material below the water line unless top coating.)

- For best results apply only over clean primed surfaces. (Use compressed air to remove any dust contamination).

- Apply using a plastic or metal spreader pressing the putty firmly into the imperfections; keep the application thickness to 1/16″ or less. Apply in thin coats instead of one thick application.

- Allow to dry prior to sanding. Sand (wet or dry) using 3M™ abrasives in the following sequence: P180, P220, P320. Note: As with any putty, longer drying times will occur with high humidity, thick applications and low temperatures.

- Re-clean surface prior to priming or top coating. (Follow paint manufacturer’s recommendation for priming and top coating).

Related products

Adhesives & Sealants

3M 08017, Marine Grade Silicone Sealant, White, 3 oz Tube, 7000120479, 6/Case

$15.76

Adhesives & Sealants

3M 05203, Marine Adhesive Sealant 5200, White, 3 oz Tube, 7000118401, 6/Case

$15.40

Adhesives & Sealants

3M 08302, Ultrapro Autobody Sealant, Clear, 5 oz Tube, 7000120449, 6 per case

$30.54

Adhesives & Sealants

3M 14345, Marine Adhesive Sealant 4000 UV, Black, 3 oz Tube, 7010367954, 6/Case

$15.34