-

×

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

400 × $1.25

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

400 × $1.25 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

2 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

2 × $192.76 -

×

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86 -

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

500 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

500 × $4.14 -

×

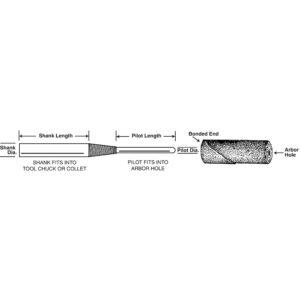

Standard Abrasives 704491, Cartridge Roll Mandrel, 3/16 in x 3/4 in x 1/4 in x 1 in x 2-3/4 in CM-15, 7000121768

5 × $4.88

Standard Abrasives 704491, Cartridge Roll Mandrel, 3/16 in x 3/4 in x 1/4 in x 1 in x 2-3/4 in CM-15, 7000121768

5 × $4.88 -

×

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33 -

×

3M 16587, Accuspray Spray Gun Kit HGP, 7000120108

1 × $333.59

3M 16587, Accuspray Spray Gun Kit HGP, 7000120108

1 × $333.59 -

×

3M 05741, Hookit Hand Block, 2-3/4 in x 7-3/4 in, 7000045716

10 × $36.94

3M 05741, Hookit Hand Block, 2-3/4 in x 7-3/4 in, 7000045716

10 × $36.94 -

×

3M 72600, 663FC 1/2" X 30", 70u Diamond Trizact Belt, 7100206529

1 × $0.00

3M 72600, 663FC 1/2" X 30", 70u Diamond Trizact Belt, 7100206529

1 × $0.00

3M 91711, Hot Melt Adhesive 3750 AE, Light Tan, 1/2 in x 10 in, 7000121331, 25 lb/case

$10.43

Factory Stock, 7-10 Day Leadtime, Priced Per LB

We formulated 3M Hot Melt Adhesive 3750 Tan to grab and seal quickly and meet the demands of high-volume production settings such as packing, woodworking and assembly. When heated to its specified melt point, this adhesive achieves a low viscosity/ high-flow rate and an aggressive hot tack that bonds to handling strength in seconds to help maintain high-tempo productivity.

Together these two properties increase the speed of carton closures and provide adhesion to wood, paperboard, corrugated and other fibrous substrates. It provides strong shear strength and low peel strength, which means your packages stay sealed and components stay bonded under most conditions. Its 30 – 40 second open time, along a 1/8″ bead, is sufficient for positioning and adjusting for fit and supports high-tempo productivity for packaging, woodworking and applications that involve fibrous materials. We manufacture 3M Hot Melt Adhesive 3750 Tan using 100% solids, thermoplastic resin for use with 3M Hot Melt Applicators. As a low-volatile-organic (VOC) compound, this adhesive produces minimal odor when heated and helps support a comfortable work environment.

About Hot Melt Adhesives

Hot melt adhesives encompass a range of characteristics. Low melt adhesives/ hot-glue sticks have a relatively low melting point that ranges between approximately 170-250F/76-121C depending on the formulation, and are applied with low-temperature applicators, commonly referred to as hot-glue guns. Low-melt adhesives are beneficial in that they can be used to bond heat sensitive materials such as foam and a range of plastics. They provide a nearly instant bond, but when the bond is reheated, some varieties will soften, allowing the bonded surfaces to be separated. The aggressive hot tack nature of low-melt adhesives speeds up production and assembly operations that involve light gauge metals, some plastics and other non-fibrous materials in addition to building display boards, floral displays and hobby projects. These adhesives are also used in manufacturing, assembly and packaging processes, window, door, construction, transportation, electronics and other industries, as well as in woodworking, assembling building store displays, convention sample boards, trophies, novelties, upholstery, furniture, audio components and cabinets.

Hot melt adhesives/hot-glue sticks have a relatively hot melting point that ranges between approximately 250-380F/121-196C, depending on the formulation, and are applied with hot-melt applicators, commonly referred to as hot-glue guns. Hot-melt glues provide a nearly instant bond between many plastics, paper and wood, but when the bond is reheated, some varieties will soften, allowing the bonded surfaces to be separated. The quick-stick nature of hot-melt adhesives speeds up operations in packaging and production.