-

×

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

800 × $1.33

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

800 × $1.33 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

1500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

1500 × $0.60 -

×

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

400 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

400 × $1.61 -

×

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57 -

×

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86 -

×

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

1000 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

1000 × $0.58 -

×

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

2000 × $0.67

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

2000 × $0.67 -

×

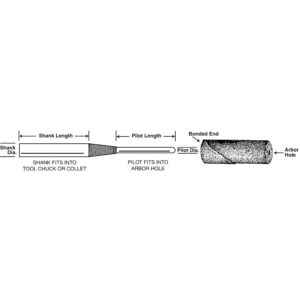

Standard Abrasives 710870, Cartridge Roll Mandrel, 1/8 in x 1/2 in x 1/4 in x 1-1/4 in x 2-1/4 in CM-7, 7000121794

5 × $4.71

Standard Abrasives 710870, Cartridge Roll Mandrel, 1/8 in x 1/2 in x 1/4 in x 1-1/4 in x 2-1/4 in CM-7, 7000121794

5 × $4.71 -

×

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

400 × $1.74

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

400 × $1.74 -

×

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03 -

×

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39 -

×

3M 17534 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 2-1/2 in x 60 in, 7010366042

10 × $46.80

3M 17534 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 2-1/2 in x 60 in, 7010366042

10 × $46.80

3M 07442, Scotch-Brite Ultra Fine Scuff Sponge, 7000120823

This item has been Discontinued.

Scotch-Brite Ultra Fine Scuff Sponge is a great hand-held cleaning agent designed to help with intermediate scuffing applications. Under a microscope, an ultra-fine grade reveals tiny, small, densely-packed mineral that counters the more aggressive cut of a denser grade abrasive. The fine grade produces a finer finish that will not compromise the geometry of the part by gouging or marring it.

An Alternative to Steel Wool

Unlike fine steel wool, Scotch-Brite Ultra Fine Scuff Sponge will not rust after use or leave fine metal splinters. The durable open-web construction is load resistant, offers long life and consistent abrasive action for cleaning and scuffing with no need to adjust, turnover or continue the same project with a new sponge. The sponge gets into corners and works detailed surfaces without altering the dimensions of the base material. Designed to run cleaner and longer than steel wool, this versatile sponge is a useful item for any workshop. It can help reduce surface prep time on a variety of applications including paint and primer preparation on airplanes, cars, trucks and other motor vehicles, scuff sanding of sealer coatings on cabinetry and furniture, refine finishes on stainless steel appliances, food processing, pharmaceutical and surgical equipment.

Designed for Comfort

Our Scotch-Brite Ultra Fine Scuff Sponge was designed with comfort and conformability in mind. The contours in the center of the sponge may help operators achieve a firmer grip, so they might apply more uniform pressure to the substrate. It comes in white, grey and maroon colors to indicate the sponges grade. The sponges material works great with water or other solvents.

The Many Benefits of Open Web Abrasives

Overall, our nonwoven technology makes Scotch-Brite industrial abrasives unique. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance, and extremely long service life. Scotch-Brite products not only enhance productivity, but also increase operator safety by reducing the need for cleaning chemicals and pastes, and replacing wire brushes that can break off and cause injury. Scotch-Brite abrasives work fast and deliver consistent results, part after part.

Related products

Diamond Unitized Wheels

3M 65087, Scotch-Brite Diamond Wheel, 3″ x 1/2″ x 3/8″ 645DC, 7100083803

$157.65