-

×

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52 -

×

3M 36876, Self-Stick Liquid Protection Fabric, Blue, 4 in x 300 ft perroll, 7100169348, 6 Rolls Per Pack

1 × $534.33

3M 36876, Self-Stick Liquid Protection Fabric, Blue, 4 in x 300 ft perroll, 7100169348, 6 Rolls Per Pack

1 × $534.33 -

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

36 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

36 × $9.52 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 175u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 175u

12 × $7.60 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58 -

×

3M 77157 Scotch-Brite Durable Flex Belt, 77157, 1/2 in x 18 in, A MED, Trial Pack, 7010365702

10 × $19.33

3M 77157 Scotch-Brite Durable Flex Belt, 77157, 1/2 in x 18 in, A MED, Trial Pack, 7010365702

10 × $19.33 -

×

3M 08857 Scotch-Brite Surface Conditioning Belt, SC-BS, A/O Medium, 1/2 in x 18 in, 7000028454, 48011088570

20 × $6.57

3M 08857 Scotch-Brite Surface Conditioning Belt, SC-BS, A/O Medium, 1/2 in x 18 in, 7000028454, 48011088570

20 × $6.57 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

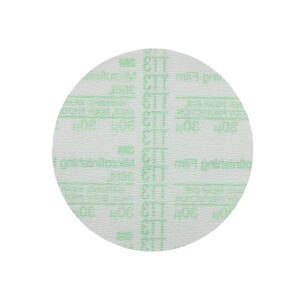

3M 76975, Microfinishing PSA Film Disc 268L, 30 Mic, Type D, Green, 5 in x NH, Die 500X, 7000118196, 500 per case

500 × $1.15

3M 76975, Microfinishing PSA Film Disc 268L, 30 Mic, Type D, Green, 5 in x NH, Die 500X, 7000118196, 500 per case

500 × $1.15 -

×

3M 48236, General Purpose Glass Cloth Tape 3615, White, 2 in x 36 yd, 7 mil, 3615, 7000123894

24 × $96.42

3M 48236, General Purpose Glass Cloth Tape 3615, White, 2 in x 36 yd, 7 mil, 3615, 7000123894

24 × $96.42 -

×

Standard Abrasives 840032, Quick Change Surface Conditioning FE Disc, A/O Medium, TSM, Maroon, 3/4 in, QS75KM, 7000046846, 50/case

50 × $0.96

Standard Abrasives 840032, Quick Change Surface Conditioning FE Disc, A/O Medium, TSM, Maroon, 3/4 in, QS75KM, 7000046846, 50/case

50 × $0.96 -

×

3M 76624, Roloc Disc 777F, 60 YF-weight, TR, 1 in, Die R100N, 7000045620

500 × $0.62

3M 76624, Roloc Disc 777F, 60 YF-weight, TR, 1 in, Die R100N, 7000045620

500 × $0.62 -

×

3M 41595, Polyurethane Sealant 540, Black, 310 mL Cartridge, 7100001804, 12/Case

12 × $9.58

3M 41595, Polyurethane Sealant 540, Black, 310 mL Cartridge, 7100001804, 12/Case

12 × $9.58 -

×

3M 70894, 641WY 1/2" X 24", 100 Mesh Diamond Cloth Belt, 7010533228

1 × $19.01

3M 70894, 641WY 1/2" X 24", 100 Mesh Diamond Cloth Belt, 7010533228

1 × $19.01 -

×

3M 27760, Hookit Microfinishing Film Disc 366L, 30 Mic 3MIL, Type D, 6 in x NH, Die 600Z, 7100049207, 500 per case

500 × $1.81

3M 27760, Hookit Microfinishing Film Disc 366L, 30 Mic 3MIL, Type D, 6 in x NH, Die 600Z, 7100049207, 500 per case

500 × $1.81 -

×

3M 47181, Polyurethane Adhesive Sealant 550FC Fast Cure, Black, 600 mL Sausage Pack, 7100197989, 12/Case

12 × $16.09

3M 47181, Polyurethane Adhesive Sealant 550FC Fast Cure, Black, 600 mL Sausage Pack, 7100197989, 12/Case

12 × $16.09 -

×

3M 31933, Hot Melt Adhesive 3750LM AE, Tan, 0.45 in x 12 in, 7100068121, 11 lb/case

11 × $13.09

3M 31933, Hot Melt Adhesive 3750LM AE, Tan, 0.45 in x 12 in, 7100068121, 11 lb/case

11 × $13.09 -

×

3M 14725, Foam and Fabric Spray Adhesive 24, Orange, 16 fl oz Can (Net Wt 13.8 oz), 7100179450, 12/Case

12 × $9.49

3M 14725, Foam and Fabric Spray Adhesive 24, Orange, 16 fl oz Can (Net Wt 13.8 oz), 7100179450, 12/Case

12 × $9.49 -

×

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67

3M 22397, Roloc Disc 361F, 60 YF-weight, TR, 1-1/2 in x NH, 7000045097

500 × $0.67 -

×

Norton 66623325035 - 2" 120 Grit Fine Grade Aluminum Oxide Vortex Rapid Prep Green TR Non-Woven Surface Preparation Disc, 50 Each

50 × $1.76

Norton 66623325035 - 2" 120 Grit Fine Grade Aluminum Oxide Vortex Rapid Prep Green TR Non-Woven Surface Preparation Disc, 50 Each

50 × $1.76 -

×

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37 -

×

Dynabrade 53244 7" Dia. Type 27 Vertical Depressed Center Wheel Grinder, 3 HP, 7,200 RPM, 5/8"-11 Spindle

1 × $1,515.78

Dynabrade 53244 7" Dia. Type 27 Vertical Depressed Center Wheel Grinder, 3 HP, 7,200 RPM, 5/8"-11 Spindle

1 × $1,515.78 -

×

Dynabrade 54039 3/8"-24 Female 5/16"-24 Female, 1" Length

1 × $89.15

Dynabrade 54039 3/8"-24 Female 5/16"-24 Female, 1" Length

1 × $89.15 -

×

3M 20928, PSA Cloth Disc 348D, P180 X-weight, 1 in x NH, Die 100N, 7000118917

500 × $0.40

3M 20928, PSA Cloth Disc 348D, P180 X-weight, 1 in x NH, Die 100N, 7000118917

500 × $0.40 -

×

3M 14593, Scotch-Brite Cut and Polish Disc, 3" x 1-1/4" x 1/4" A Medium, D5, 7000045941, Box of 10

10 × $16.71

3M 14593, Scotch-Brite Cut and Polish Disc, 3" x 1-1/4" x 1/4" A Medium, D5, 7000045941, Box of 10

10 × $16.71 -

×

3M 71346, 675L, 1" X 120", 125u, Diamond Microfinishing Film Belts, 7010534823

1 × $97.89

3M 71346, 675L, 1" X 120", 125u, Diamond Microfinishing Film Belts, 7010534823

1 × $97.89 -

×

3M 49941, Roloc Disc 361F, 80 YF-weight, TSM, 3 in, Die RS300VM, 7000148151

200 × $1.33

3M 49941, Roloc Disc 361F, 80 YF-weight, TSM, 3 in, Die RS300VM, 7000148151

200 × $1.33 -

×

3M 94717, Cubitron ll Cloth Belt 947A, 80+ X-weight, 1 in x 30 in, Fabri-lok, Single-flex, 7010294445, 200 per case

200 × $3.73

3M 94717, Cubitron ll Cloth Belt 947A, 80+ X-weight, 1 in x 30 in, Fabri-lok, Single-flex, 7010294445, 200 per case

200 × $3.73 -

×

3M 01333, PSA Cloth Disc 348D, 60 X-weight, 3 in x NH, Die 300V, 7000118880

200 × $0.94

3M 01333, PSA Cloth Disc 348D, 60 X-weight, 3 in x NH, Die 300V, 7000118880

200 × $0.94 -

×

Dynabrade 78322 3" Dia. x 1" W x 1/4" Shank, Very Fine, NWN DynaBrite Wheel, 10/pack

10 × $15.85

Dynabrade 78322 3" Dia. x 1" W x 1/4" Shank, Very Fine, NWN DynaBrite Wheel, 10/pack

10 × $15.85

Standard Abrasives 875511, Buff and Blend AP Mounted Flap Brush, 3 in x 2 in x 1/4 in, A MED, 7000122220

$27.01

Factory Stock, 7-10 Day Leadtime

Both tough and pliable, our Standard Abrasives Buff and Blend Mounted AP Flap Brush is a good match for medium duty cleaning applications on parts with irregular or intricate shapes. The soft AP material works well for medium duty cleaning, and antique finishing on a variety of metals, including ferrous alloys, and the mounted brush securely attaches to small straight tools with ease.

Increased Pliability for Ridges, Contours, and Irregular Surfaces

The Standard Abrasives™ Buff and Blend Mounted Flap Brush balances an aggressive cut with softness and pliability. The thinnest and most pliable of the Buff and Blend non-woven materials, AP material is designed for removing small metal burrs, scratches and contaminants in hard-to-reach areas or places where cleaning may be difficult due to an irregular-shaped surface.

The spongy, open web is flexible, responsive and conforms to irregular surfaces. Using Standard Abrasives™ Buff and Blend discs, wheels and brushes, operators can tackle ridges and contours with less concern about gouging or marring the substrate, thus reducing waste and the need for rework.

Medium Grade Aluminum Oxide Works Efficiently

This flap brush is made with tough, sharp-cutting aluminum oxide mineral. The medium grade (MED) brush delivers a somewhat coarse scratch pattern, suitable for satin or matte finishes. When you need a product that is more aggressive than a flap brush, choose a Standard Abrasives™ Combi-Wheel or Flap Wheel.

Consistent Finishes, Operator Comfort

Flap brushes produce a consistent finish which does not reflect lines commonly attributed with ganged arbor hole discs. Density, pressure and angle determine the ability of the flap brush to remove burrs, oxidation and handling marks. The abrasive material provides ventilation which helps dissipate heat and, therefore, runs cooler. This provides consistent finishes and reduces the risk of smearing or otherwise discoloring the work piece. Minimal vibration can reduce chattermarks on the workpiece and can lead to less operator and machine fatigue.

The permanently affixed 1/4? shank enables convenient use on small straight pneumatic and electric grinders, and provides smooth running and ease of control for off-hand operations.

Load-Resistant Construction Boosts Life and Performance

Standard Abrasives™ Buff and Blend products are load-resistant to keep you cutting with fresh mineral. The gaps in the open web allow unwanted swarf to escape. Consequently, less debris clogs the abrasive, so the mineral can stay fresh, keep cutting sharp and deliver a consistent cut over the life of the product. As the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface, contributing to cleaner surfaces and less re-work. Furthermore, manual fatigue that may result from applying heavy pressure to a dull abrasive is reduced.

The Many Benefits of Standard Abrasives™ Buff and Blend Products

Standard Abrasives™ Buff and Blend products invigorate deburring, cleaning, blending and finishing applications by helping operators reduce finishing steps, minimize costs and achieve greater throughput. Each Buff and Blend product and grade offers unique benefits, so operators can choose from a versatile range of options to ensure superior performance on specific applications.