-

×

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52 -

×

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

3M 08857 Scotch-Brite Surface Conditioning Belt, SC-BS, A/O Medium, 1/2 in x 18 in, 7000028454, 48011088570

20 × $6.57

3M 08857 Scotch-Brite Surface Conditioning Belt, SC-BS, A/O Medium, 1/2 in x 18 in, 7000028454, 48011088570

20 × $6.57 -

×

3M 08916 Scotch-Brite Surface Conditioning Belt, SC-BS, A/O Medium, 2 in x 60 in, 7010309628

10 × $30.29

3M 08916 Scotch-Brite Surface Conditioning Belt, SC-BS, A/O Medium, 2 in x 60 in, 7010309628

10 × $30.29 -

×

3M 15145 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 1 in x 132 in, 7010364529

5 × $31.68

3M 15145 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 1 in x 132 in, 7010364529

5 × $31.68 -

×

3M 00581 Scotch-Brite Surface Conditioning Belt, SC-BS, A/O Medium, 2-1/2 in x 60 in, 7010329198

10 × $37.87

3M 00581 Scotch-Brite Surface Conditioning Belt, SC-BS, A/O Medium, 2-1/2 in x 60 in, 7010329198

10 × $37.87

3M 14783, Scotch-Brite Roloc Finishing Flap Brush, 3 in x 1-3/8 in S FIN, 7000077968

$25.29

Factory Stock, 7-10 Day Leadtime

Scotch-Brite Roloc Finishing Flap Brush is constructed from sections of non-woven material slit lengthwise and bonded to a cylindrical core. Its durable yet responsive design make it ideal for finishing applications.

Improved Consistency and Greater Control

Scotch-Brite Roloc Finishing Flap Brush requires no chemical compounds to achieve fine finishes and is ideal for all aesthetic finishing applications, smoothing wood fibers, defuzzing wood, plastic, and composite surfaces and sealer scuffing. This long-lasting brush provides improved consistency and greater control over a number of critical prep and finishing tasks, such as brushed finishes on copper, brass, stainless steel, aluminum and other metals.

Made with Aluminum Oxide Mineral and Roloc Attachment System

We designed our Scotch-Brite Roloc Finishing Flap Brush with aluminum oxide mineral in the CRS grade and silicon carbide in the FIN grade. Aluminum oxide is used for its high cut-rate, hardness, strength, and low heat retention, aluminum oxide mineral is widely used in grinding applications in addition to sanding and finishing use. Aluminum oxide is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys. Silicon carbide is used for finer finishing and offers a very sharp mineral to create different aesthetic finishes. Additionally, we included a Roloc attachment on our Scotch-Brite Roloc Finishing Flap Brush to make brush to tool attachment swift and easy.

The Many Benefits of Open Web Abrasives

Nonwoven technology makes our Scotch-Brite industrial abrasives unique. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance, and extremely long service life. Scotch-Brite products may enhance productivity while reducing the need for cleaning chemicals and wire brushes. From aesthetic finishing to weld blending, deburring, and more, Scotch-Brite abrasives work fast and deliver consistent results, part after part.

Related products

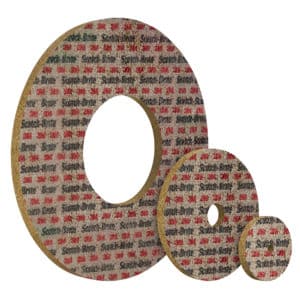

Diamond Unitized Wheels

3M 65087, Scotch-Brite Diamond Wheel, 3″ x 1/2″ x 3/8″ 645DC, 7100083803

$107.65