-

×

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95 -

×

3M 71346, 675L, 1" X 120", 125u, Diamond Microfinishing Film Belts, 7010534823

1 × $97.89

3M 71346, 675L, 1" X 120", 125u, Diamond Microfinishing Film Belts, 7010534823

1 × $97.89 -

×

3M 14895, Cloth Belt 777F, 80 YF-weight, 1 in x 42 in, Film-lok, Single-flex, 7010299926, 200 per case

200 × $4.46

3M 14895, Cloth Belt 777F, 80 YF-weight, 1 in x 42 in, Film-lok, Single-flex, 7010299926, 200 per case

200 × $4.46 -

×

Standard Abrasives 41460, Aluminum Oxide Overlap Disc, 715803, 120 Grit, 1 in x 8-32 x 2 Ply, 7100092203

100 × $2.42

Standard Abrasives 41460, Aluminum Oxide Overlap Disc, 715803, 120 Grit, 1 in x 8-32 x 2 Ply, 7100092203

100 × $2.42 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $699.72

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $699.72 -

×

Dynabrade 91425 1/4" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.07

Dynabrade 91425 1/4" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.07

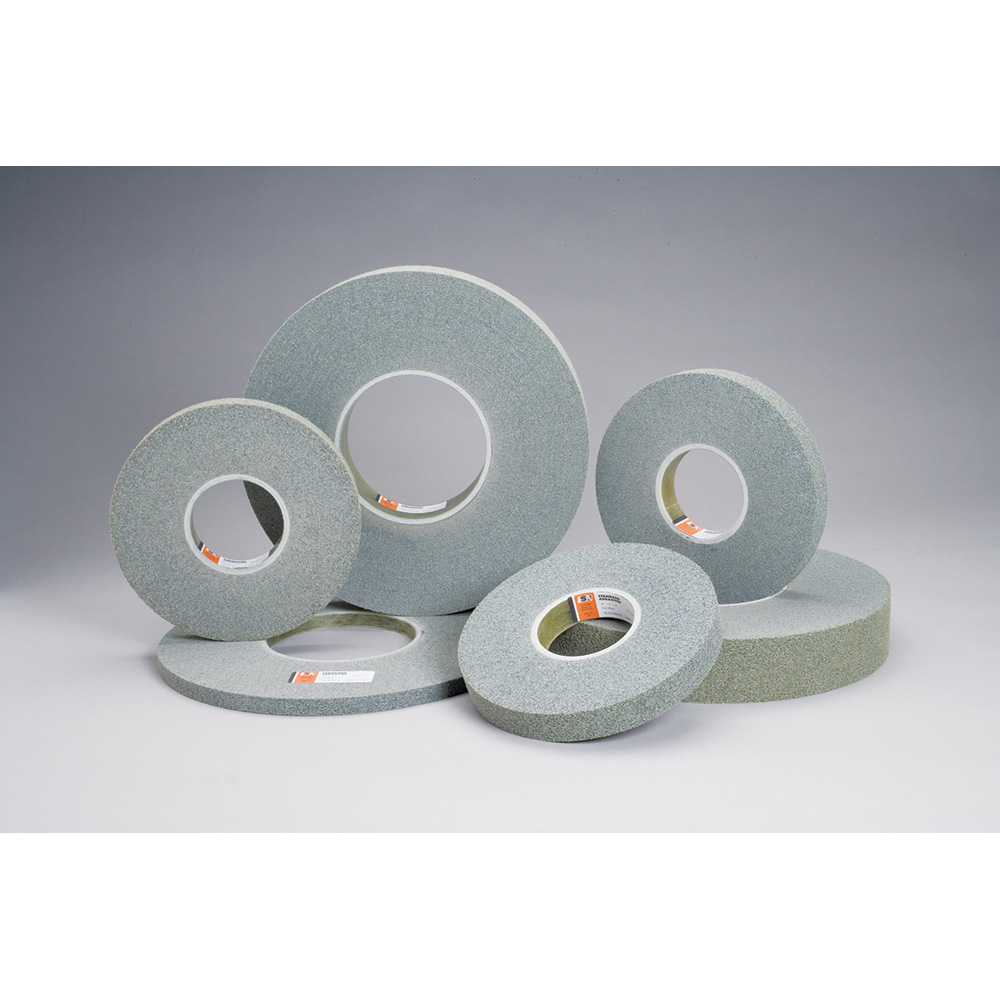

Standard Abrasives 853333, LDW Wheel 8 in x 1 in x 3 in 8S FIN, 7010301237

$111.35

Factory Stock, 7-10 Day Leadtime

The Standard Abrasives Light Deburring Wheel finishes and deburrs parts with critical tolerances and may be used on automated equipment, straight shaft stationary and portable tools as well as feed-through machines.