-

×

Dynabrade 53065 Housing Ass'y for 53094

1 × $296.09

Dynabrade 53065 Housing Ass'y for 53094

1 × $296.09 -

×

Dynabrade 66431 Contact Wheel

1 × $361.27

Dynabrade 66431 Contact Wheel

1 × $361.27 -

×

Dynabrade 54541 Spindle

1 × $250.81

Dynabrade 54541 Spindle

1 × $250.81 -

×

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $409.44

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $409.44 -

×

Dynabrade 53208 Exhaust Cover

1 × $98.89

Dynabrade 53208 Exhaust Cover

1 × $98.89 -

×

Dynabrade 01378 Air Control Ring

1 × $18.25

Dynabrade 01378 Air Control Ring

1 × $18.25 -

×

Dynabrade 61123 High Efficiency Collection Filter Bag (15-22 Gallon)

1 × $34.73

Dynabrade 61123 High Efficiency Collection Filter Bag (15-22 Gallon)

1 × $34.73 -

×

Dynabrade 65339 Contact Wheel Ass'y

1 × $758.21

Dynabrade 65339 Contact Wheel Ass'y

1 × $758.21 -

×

Dynabrade 54515 Spacer

1 × $37.17

Dynabrade 54515 Spacer

1 × $37.17 -

×

Dynabrade 97143 - 1/2" NPT Plug

1 × $3.10

Dynabrade 97143 - 1/2" NPT Plug

1 × $3.10 -

×

Dynabrade 97120 Shim

1 × $5.12

Dynabrade 97120 Shim

1 × $5.12 -

×

Dynabrade 58969 Housing Assy for Model # 59009 Rev. H

1 × $95.66

Dynabrade 58969 Housing Assy for Model # 59009 Rev. H

1 × $95.66 -

×

Dynabrade 53978 - 5" (127 mm) Interface Pad, Double-Sided Hook-Face

1 × $13.21

Dynabrade 53978 - 5" (127 mm) Interface Pad, Double-Sided Hook-Face

1 × $13.21 -

×

Dynabrade 58673 Spindle Angle Head Shaft

1 × $300.37

Dynabrade 58673 Spindle Angle Head Shaft

1 × $300.37 -

×

Dynabrade 40752 Switch Button

1 × $6.46

Dynabrade 40752 Switch Button

1 × $6.46 -

×

Dynabrade 52672 1 hp Straight-Line 6" (152 mm) Extension Die Grinder, Rear Exhaust, 3,400 RPM, 1/4" Collet

1 × $1,017.23

Dynabrade 52672 1 hp Straight-Line 6" (152 mm) Extension Die Grinder, Rear Exhaust, 3,400 RPM, 1/4" Collet

1 × $1,017.23 -

×

Dynabrade 01371 Lock Ring

1 × $70.53

Dynabrade 01371 Lock Ring

1 × $70.53 -

×

Dynabrade 98240 115V DC Motor, 1/2HP

1 × $2,368.96

Dynabrade 98240 115V DC Motor, 1/2HP

1 × $2,368.96 -

×

Dynabrade 98139 S.C.R.Reversing Motor Control, 115V

1 × $2,532.33

Dynabrade 98139 S.C.R.Reversing Motor Control, 115V

1 × $2,532.33 -

×

Dynabrade 97993 Motor, 1.5 hp, 1,800 RPM, 3 Phase, 208 V - 230/460 V

1 × $2,140.16

Dynabrade 97993 Motor, 1.5 hp, 1,800 RPM, 3 Phase, 208 V - 230/460 V

1 × $2,140.16 -

×

Dynabrade 54469 Spacer

1 × $19.86

Dynabrade 54469 Spacer

1 × $19.86 -

×

Dynabrade 93587 1" Dia. x 3-48 Female Center Thread, 120 Grit, A/O, 3-Ply, J-DynaCut Eyelet Star, 50/pack

50 × $2.94

Dynabrade 93587 1" Dia. x 3-48 Female Center Thread, 120 Grit, A/O, 3-Ply, J-DynaCut Eyelet Star, 50/pack

50 × $2.94 -

×

Dynabrade 98137 Speed Pot Kit

1 × $74.28

Dynabrade 98137 Speed Pot Kit

1 × $74.28 -

×

Dynabrade 53330 Bearing, 28 x 15 x 7, Shielded

1 × $8.00

Dynabrade 53330 Bearing, 28 x 15 x 7, Shielded

1 × $8.00 -

×

Dynabrade 40330 Vacuum Dynafile II Abrasive Belt Tool

1 × $959.49

Dynabrade 40330 Vacuum Dynafile II Abrasive Belt Tool

1 × $959.49 -

×

Dynabrade 58510 3" W x 4" L (76 mm x 102 mm) Dynabug II Orbital Sander, Non-Vacuum

1 × $237.04

Dynabrade 58510 3" W x 4" L (76 mm x 102 mm) Dynabug II Orbital Sander, Non-Vacuum

1 × $237.04 -

×

Dynabrade 48535 3" Dia. Epic Finish Kit With 48531 Geared Disc Sander, Rear Exhaust, .4 HP, 15,000 RPM

1 × $586.50

Dynabrade 48535 3" Dia. Epic Finish Kit With 48531 Geared Disc Sander, Rear Exhaust, .4 HP, 15,000 RPM

1 × $586.50 -

×

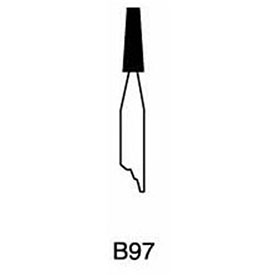

Dynabrade 78742 1/8" x 3/8"-B97 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $2.03

Dynabrade 78742 1/8" x 3/8"-B97 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $2.03 -

×

Dynabrade 54475 Shaft

1 × $7.31

Dynabrade 54475 Shaft

1 × $7.31 -

×

Dynabrade 97442 Retaining Ring

1 × $2.46

Dynabrade 97442 Retaining Ring

1 × $2.46 -

×

Dynabrade 40353 Dynafile II Abrasive Belt Tool, for Non-Woven Nylon Belts

1 × $688.35

Dynabrade 40353 Dynafile II Abrasive Belt Tool, for Non-Woven Nylon Belts

1 × $688.35 -

×

Dynabrade 01788 Screw

1 × $1.93

Dynabrade 01788 Screw

1 × $1.93 -

×

Dynabrade 54544 .002" Shim

1 × $6.33

Dynabrade 54544 .002" Shim

1 × $6.33 -

×

Dynabrade 64400 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Down Exhaust

1 × $27,619.39

Dynabrade 64400 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Down Exhaust

1 × $27,619.39 -

×

Dynabrade 58512 2-3/4" W x 7-3/4" L Dynabug II Orbital Sander, Central-Vacuum, .15 hp, 10,000 RPM, 3/32" Orbit

1 × $266.78

Dynabrade 58512 2-3/4" W x 7-3/4" L Dynabug II Orbital Sander, Central-Vacuum, .15 hp, 10,000 RPM, 3/32" Orbit

1 × $266.78 -

×

Dynabrade 55671 Lockout Spring

1 × $8.83

Dynabrade 55671 Lockout Spring

1 × $8.83 -

×

Dynabrade 53180 Planetary Carrier

1 × $152.37

Dynabrade 53180 Planetary Carrier

1 × $152.37 -

×

Dynabrade 43516 .4 hp 6" (152 mm) Dia. Extension Die Grinder, Rear Exhaust, 25,000 RPM, 1/4" Collet

1 × $738.21

Dynabrade 43516 .4 hp 6" (152 mm) Dia. Extension Die Grinder, Rear Exhaust, 25,000 RPM, 1/4" Collet

1 × $738.21 -

×

Dynabrade 78538 3/4"Dia. 2-Set, 3-48 Female Center Thread, 80 Grit, Dynacut A/O Overlap Slotted Disc, 100/pack

100 × $1.10

Dynabrade 78538 3/4"Dia. 2-Set, 3-48 Female Center Thread, 80 Grit, Dynacut A/O Overlap Slotted Disc, 100/pack

100 × $1.10 -

×

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $370.16

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $370.16 -

×

Dynabrade 01794 Rubber Drive Wheel

1 × $279.95

Dynabrade 01794 Rubber Drive Wheel

1 × $279.95 -

×

Dynabrade 90631 3" W x 7-3/8" L 60 Grit A/Z DynaCut Belt, 10/ Pack

10 × $3.40

Dynabrade 90631 3" W x 7-3/8" L 60 Grit A/Z DynaCut Belt, 10/ Pack

10 × $3.40 -

×

Dynabrade 91428 1/2" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.20

Dynabrade 91428 1/2" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.20 -

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $27,619.39

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $27,619.39 -

×

Dynabrade 54912 Gear Set, 8500 RPM, 2.6Hp

1 × $393.73

Dynabrade 54912 Gear Set, 8500 RPM, 2.6Hp

1 × $393.73 -

×

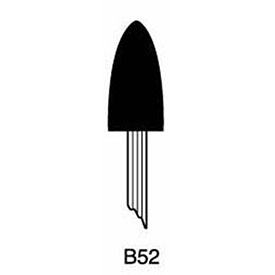

Dynabrade 78709 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46

Dynabrade 78709 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46 -

×

Dynabrade 90924 3" Dia. x 40 Grit A/Z DynaCut Locking-Type (TR), Flap Disc, 10/pack

10 × $4.30

Dynabrade 90924 3" Dia. x 40 Grit A/Z DynaCut Locking-Type (TR), Flap Disc, 10/pack

10 × $4.30 -

×

Dynabrade 54568 Assembly Tool

1 × $153.31

Dynabrade 54568 Assembly Tool

1 × $153.31 -

×

Dynabrade 92116 1/2" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.20

Dynabrade 92116 1/2" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.20 -

×

Dynabrade 90405 1/8" W x 24" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $0.79

Dynabrade 90405 1/8" W x 24" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $0.79 -

×

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $699.72

Dynabrade 14000 Dynafile Abrasive Belt Tool

1 × $699.72 -

×

Dynabrade 82577 1/2" W x 24" L 80 Grit Ceramic DynaCut Belt, 50/pack

50 × $3.19

Dynabrade 82577 1/2" W x 24" L 80 Grit Ceramic DynaCut Belt, 50/pack

50 × $3.19 -

×

Dynabrade 11218 Contact Arm Ass'y, 5/8" Dia. x 3/8" W, Rubber Wheel, with 1/2" W Platen

1 × $69.58

Dynabrade 11218 Contact Arm Ass'y, 5/8" Dia. x 3/8" W, Rubber Wheel, with 1/2" W Platen

1 × $69.58 -

×

Dynabrade 94990 1/4" Female Composite-Style Coupler with 1/4" Male Plug Assembly

1 × $40.31

Dynabrade 94990 1/4" Female Composite-Style Coupler with 1/4" Male Plug Assembly

1 × $40.31 -

×

Dynabrade 92151 1/2" W x 18" L 120 Grit Ceramic DynaCut Scalloped Edge Belt, 50/pack

100 × $4.35

Dynabrade 92151 1/2" W x 18" L 120 Grit Ceramic DynaCut Scalloped Edge Belt, 50/pack

100 × $4.35 -

×

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

200 × $0.97

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

200 × $0.97

Standard Abrasives 850315, Quick Change Buff and Blend HP Disc, Very Fine, TSM, 2 in, 7000046991, 50 per case

$1.61

Factory Stock, 7-10 Day Leadtime

Made of non-woven material with added stiffness, our Standard Abrasive Quick Change Buff and Blend HP Disc has a durable web designed for applications such as removal of burrs or tough contaminants, and can be used on a variety of substrates. The quick change system offers both convenience and a secure attachment to the tool, enhancing operator efficiency and productivity.

Added Durability for Challenging Surfaces

We designed our Standard Abrasives™ Quick Change Buff and Blend HP Disc to conveniently and efficiently perform light deburring and aggressive cleaning on a variety of metal substrates: ferrous and non-ferrous metals, aluminum, high nickel and stainless steel. The tough nylon web offers sustained performance without tearing and leaves a consistent finish on the workpiece, meaning less or maybe even no rework is required. This disc features very fine (VFN) grade aluminum oxide mineral, which cuts sharp for efficient blending. Among the four Standard Abrasives™ Buff and Blend materials, HP material is moderately stiff, durable and aggressive, and we recommend starting here for deburring applications. Its non-woven construction makes the material responsive to contours and extrusions, so you no longer have to worry about gouging or marring the substrate.

Our HP Disc is a smart choice when you need to remove part lines from small castings, small burrs from threaded pipes, burrs from aluminum extrusions or die cast flashing, or heavy surface oxidation. Its durability results in a long service life, helping to reduce the need for replacements. Moreover, the sturdy material stands up to edges and extrusions, minimizing edge fraying and grain shedding. If greater durability is desired for heavier-duty applications such as edge deburring, we recommend upgrading to one of our Standard Abrasives™ Buff and Blend High Strength (HS) Discs.

Quick Change Discs for Higher Productivity

Standard Abrasives™ Quick Change Buff and Blend Discs are available in disc diameters up to 5″. Quick change discs allow tool-free swap outs, maintain secure attachment at high speeds, and save operators time when switching discs between grades or applications. Easy fastening and swapping of discs enhances tool efficiency and worker productivity. Choose the disc compatible with your TR or TS holder pad. TR discs have a nylon threaded male hub that easily threads onto TR or 3M™ Roloc™ type holder pads with a turn of the wrist, and the TS system has a metal hub that fastens to its holder pad with a simple twist.

The Many Benefits of Standard Abrasives™ Non-Woven Products

Standard Abrasives™ Buff and Blend non-woven products offer many benefits. Varying Buff and Blend materials help distinguish Buff and Blend products from each other, but all Buff and Blend products have an open web. The open web combines abrasive mineral and non-woven nylon fibers with a resin-reinforced bond. The resin bond securely anchors mineral to the fibers, making for a strong, durable abrasive.

Gaps between fibers allow swarf to escape, so the abrasive does not get clogged with debris. Minimizing swarf and debris prolongs abrasive service life and keeps minerals cutting sharper for longer. Nylon fibers won’t splinter during grinding, offering a good alternative to steel wool. Moreover, as the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface. Standard Abrasives™ Buff and Blend products deliver a consistent cut and finish – part after part.

Quality Standard Abrasives™ Solutions for Industrial Applications

The Standard Abrasives brand has supplied quality abrasives to the metalworking industry for over 50 years. Customers rely on our broad offering of high performance products including coated, bonded, and non-woven abrasive lines.