-

×

3M 53534, Scotch Box Sealing Tape 313, Clear 48 mm x 1500 m, 6 Rolls/Case, 7100240703

12 × $61.83

3M 53534, Scotch Box Sealing Tape 313, Clear 48 mm x 1500 m, 6 Rolls/Case, 7100240703

12 × $61.83 -

×

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

2 × $1,448.42

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

2 × $1,448.42 -

×

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

2 × $1,925.99

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

2 × $1,925.99 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $104.07

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $104.07 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,583.72

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,583.72 -

×

3M 26109, PPS Series 2.0 Adapter, Type S23, 1/4 Female, 18 Thread NPS, 7100135941

4 × $25.96

3M 26109, PPS Series 2.0 Adapter, Type S23, 1/4 Female, 18 Thread NPS, 7100135941

4 × $25.96 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,509.65

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,509.65 -

×

3M 55656, Stikit Film Disc w/Tab 375L, P240, 5 in x NH, Die 500X, 7100106552, 250 per case

250 × $0.50

3M 55656, Stikit Film Disc w/Tab 375L, P240, 5 in x NH, Die 500X, 7100106552, 250 per case

250 × $0.50 -

×

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $963.87

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $963.87 -

×

Dynabrade 15360 Dynafile III Abrasive Belt Machine for 24" Belts

1 × $896.53

Dynabrade 15360 Dynafile III Abrasive Belt Machine for 24" Belts

1 × $896.53 -

×

Dynabrade 54705 Rotor/Vane Set

1 × $110.19

Dynabrade 54705 Rotor/Vane Set

1 × $110.19 -

×

Dynabrade 18426 Vane Set (4pk)

1 × $20.20

Dynabrade 18426 Vane Set (4pk)

1 × $20.20 -

×

Dynabrade 96247 Repair Collar-1-3/16" Bore

1 × $27.09

Dynabrade 96247 Repair Collar-1-3/16" Bore

1 × $27.09 -

×

3M 80510, Roloc Disc 777F, P120 YF-weight, TR, 1 in, Die R100N, 7000045622

500 × $0.62

3M 80510, Roloc Disc 777F, P120 YF-weight, TR, 1 in, Die R100N, 7000045622

500 × $0.62 -

×

Standard Abrasives 840138,Quick Change Surface Conditioning GP Disc, Medium, TSM, 1 in, 7000121649, 50 per case

50 × $0.86

Standard Abrasives 840138,Quick Change Surface Conditioning GP Disc, Medium, TSM, 1 in, 7000121649, 50 per case

50 × $0.86 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

Standard Abrasives 722809, PSA A/O Extra Disc, 5 in x NH, 60, 7010368721

50 × $1.22

Standard Abrasives 722809, PSA A/O Extra Disc, 5 in x NH, 60, 7010368721

50 × $1.22 -

×

3M 34784, 663FC, 3" X 30", 20u, Trizact Diamond Belt, 7100063665

1 × $0.00

3M 34784, 663FC, 3" X 30", 20u, Trizact Diamond Belt, 7100063665

1 × $0.00 -

×

3M 29831, Sanding Screen, 180 Grit, 18 in x NH, 7100160238

12 × $5.83

3M 29831, Sanding Screen, 180 Grit, 18 in x NH, 7100160238

12 × $5.83 -

×

3M 26018, PPS Series 2.0 Adapter, Type S11, 3/8 Male, 18 Thread NPS, 7100135942

1 × $25.96

3M 26018, PPS Series 2.0 Adapter, Type S11, 3/8 Male, 18 Thread NPS, 7100135942

1 × $25.96 -

×

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle, RightAngle, 7000058900

24 × $168.76

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle, RightAngle, 7000058900

24 × $168.76 -

×

3M 09413, Scotch-Brite Contour Surface Paint and Varnish Remover 9413NA, 7000052005

10 × $5.79

3M 09413, Scotch-Brite Contour Surface Paint and Varnish Remover 9413NA, 7000052005

10 × $5.79 -

×

Dynabrade 78763 2" Dia. x 2" W x 1/4" Shank, Coarse, NWN DynaBrite Wheel, 10/pack

10 × $135.90

Dynabrade 78763 2" Dia. x 2" W x 1/4" Shank, Coarse, NWN DynaBrite Wheel, 10/pack

10 × $135.90 -

×

3M 27359, Cloth Belt 970DZ, 24 YN-weight, 25 in x 75 in, Film-lok, Single-flex, 7010361224, 2 per case

2 × $206.61

3M 27359, Cloth Belt 970DZ, 24 YN-weight, 25 in x 75 in, Film-lok, Single-flex, 7010361224, 2 per case

2 × $206.61 -

×

3M 05049, Cloth Belt 384F, 80+ XF-weight, 1 in x 30 in, Fabri-lok, Full-flex, 7100141431, 200 per case

200 × $1.92

3M 05049, Cloth Belt 384F, 80+ XF-weight, 1 in x 30 in, Fabri-lok, Full-flex, 7100141431, 200 per case

200 × $1.92 -

×

3M 87179, Scotch-Weld Epoxy Adhesive 2216NS, Tan, Part B, 5 Gallon Drum (Pail), 7010309882

5 × $519.53

3M 87179, Scotch-Weld Epoxy Adhesive 2216NS, Tan, Part B, 5 Gallon Drum (Pail), 7010309882

5 × $519.53

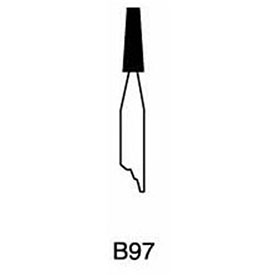

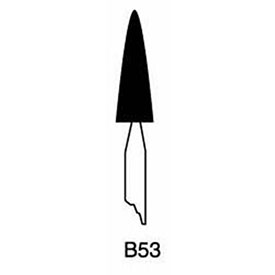

Standard Abrasives 877062, Unitized Mounted Point, 821 A11 x 1/4 in, 3M 7000122040

$22.57

Factory Stock, 7-10 Day Leadtime

Our Standard Abrasives Unitized Mounted Point lightly deburrs, blends and finishes metal and plastic parts. Choose from many different shapes and sizes to match specific small parts with hard-to-reach areas. Unitized mounted points deburr and finish without altering the shape of the workpiece, and self-dress to continually expose fresh mineral during use for efficient operations.

Suitable Shapes and Sizes for a Variety of Workpieces

Our Standard Abrasives™ Unitized Mounted Point comes in a variety of ANSI (American National Standards Institute) shapes and sizes, ideal for light blending and deburring of smaller workpieces. The variety of abrasive sizes helps operators effectively finish various parts. The abrasive point comes permanently fastened to a metal spindle so it can be securely run at high speed with a die grinder.

Unitized Products Excel at Consistent Finishes

Our Standard Abrasives™ Unitized Mounted Point reduces the risk for smearing or blemishing the surface. It also features non-woven web that is load resistant and keeps the abrasive minerals cutting at high performance by limiting clogging of the nylon fibers.

Unitized products are produced by compressing and curing multiple layers of abrasive material together. The tough, layered, unitized construction gives the abrasive higher density and more durability, making our Standard Abrasives™ Unitized Mounted Point ideal for small workpieces that require a consistent finish. As the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface, contributing to cleaner surfaces and less re-work. Furthermore, manual fatigue that may result from applying heavy pressure to a dull abrasive is reduced.

Super Sharp Silicon Carbide Leaves a Fine Finish

Silicon Carbide is harder and sharper than either aluminum oxide or zirconia alumina. It is most commonly used for low-pressure applications such as paint prep and the final stages of whitewood sanding. While it may have a shorter life than aluminum oxide, it produces a finer, brighter finish.

The unitized mounted points are color-coded by grade for easy identification in the workroom. Coarse grade points are dark gray, medium grade points are blue, and fine grade points are light gray.

The Many Benefits of Standard Abrasives™ Non-Woven Products

Standard Abrasives™ Unitized products offer many benefits for heavy-duty jobs. They invigorate deburring, cleaning, blending and finishing applications by helping operators reduce finishing steps, minimize costs and achieve greater throughput.