-

×

3M 66617, Cloth Belt 341D, 50 X-weight, 3 in x 24 in, Fabri-lok, Single-flex, 7000118857, 25 per case

25 × $3.44

3M 66617, Cloth Belt 341D, 50 X-weight, 3 in x 24 in, Fabri-lok, Single-flex, 7000118857, 25 per case

25 × $3.44 -

×

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95 -

×

Dynabrade 11253 Contact Arm Assy

1 × $525.64

Dynabrade 11253 Contact Arm Assy

1 × $525.64 -

×

3M 69455, Cloth Belt 777F, 50 YF-weight, 3 in x 132 in, Film-lok, L-flex, 7010365062, 25 per case

25 × $29.82

3M 69455, Cloth Belt 777F, 50 YF-weight, 3 in x 132 in, Film-lok, L-flex, 7010365062, 25 per case

25 × $29.82 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38 -

×

Standard Abrasives 701616, PSA A/O Disc, 12 in x NH, 50, 7010369977

10 × $6.01

Standard Abrasives 701616, PSA A/O Disc, 12 in x NH, 50, 7010369977

10 × $6.01 -

×

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

1000 × $0.73

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

1000 × $0.73 -

×

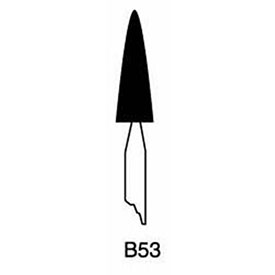

Dynabrade 78725 5/16" x 5/8"-B53 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46

Dynabrade 78725 5/16" x 5/8"-B53 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46 -

×

3M 41597, Polyurethane Adhesive Sealant 560, Black, 310 mL Cartridge, 7100005901, 12/Case

12 × $14.64

3M 41597, Polyurethane Adhesive Sealant 560, Black, 310 mL Cartridge, 7100005901, 12/Case

12 × $14.64 -

×

3M 53034, 663FC, 3/4" X 90", 20u, Diamond Trizact Belt 7100205969

1 × $359.45

3M 53034, 663FC, 3/4" X 90", 20u, Diamond Trizact Belt 7100205969

1 × $359.45 -

×

3M 84177, Microfinishing PSA Film Disc Roll 366L, 30 Mic 3MIL, Type D, 5 in x NH, Die 500X, 7000118206, 125 discs per roll

4 × $112.92

3M 84177, Microfinishing PSA Film Disc Roll 366L, 30 Mic 3MIL, Type D, 5 in x NH, Die 500X, 7000118206, 125 discs per roll

4 × $112.92 -

×

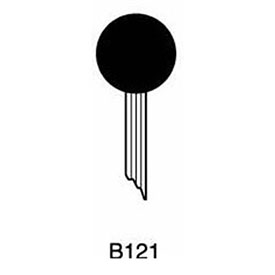

Dynabrade 78749 1/2" x 1/2"-B121 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $2.34

Dynabrade 78749 1/2" x 1/2"-B121 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $2.34 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 250u

24 × $8.20

ACS CX1250 Diamond Belt, 1/2" X 24" 250u

24 × $8.20 -

×

3M 76751, Roloc Disc 777F, 60 YF-weight, TS, 3 in, Die RS300V, 7010363900

200 × $1.43

3M 76751, Roloc Disc 777F, 60 YF-weight, TS, 3 in, Die RS300V, 7010363900

200 × $1.43 -

×

3M 25705, Scotch-Brite Roloc Surface Conditioning Disc, SC-DR, A/O Medium, TR, 3/4 in, 7000120983, 200/case

200 × $0.89

3M 25705, Scotch-Brite Roloc Surface Conditioning Disc, SC-DR, A/O Medium, TR, 3/4 in, 7000120983, 200/case

200 × $0.89 -

×

Dynabrade 15003 Mini-Dynafile II Abrasive Belt Tool

1 × $680.48

Dynabrade 15003 Mini-Dynafile II Abrasive Belt Tool

1 × $680.48 -

×

3M 05205, Marine Adhesive Sealant 5200, Black, 3 oz Tube, 7000118402, 6/Case

6 × $15.40

3M 05205, Marine Adhesive Sealant 5200, Black, 3 oz Tube, 7000118402, 6/Case

6 × $15.40 -

×

3M 88903, PSA Cloth Disc 348D, 60 X-weight, 12 in x NH, Die 1200B, 7000118896

10 × $7.75

3M 88903, PSA Cloth Disc 348D, 60 X-weight, 12 in x NH, Die 1200B, 7000118896

10 × $7.75 -

×

Dynabrade 31920 - 1-1/4" (32 mm) Static Conductive Hose, Black

1 × $15.06

Dynabrade 31920 - 1-1/4" (32 mm) Static Conductive Hose, Black

1 × $15.06 -

×

Standard Abrasives 722809, PSA A/O Extra Disc, 5 in x NH, 60, 7010368721

50 × $1.22

Standard Abrasives 722809, PSA A/O Extra Disc, 5 in x NH, 60, 7010368721

50 × $1.22 -

×

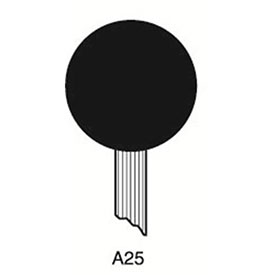

Dynabrade 78750 1" x 1"-A25 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $3.27

Dynabrade 78750 1" x 1"-A25 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $3.27

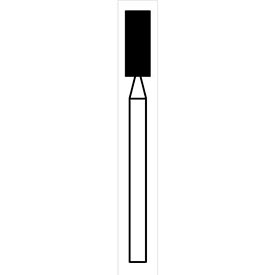

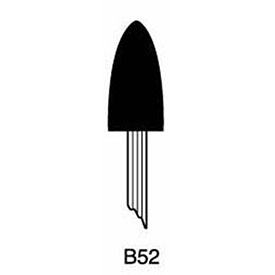

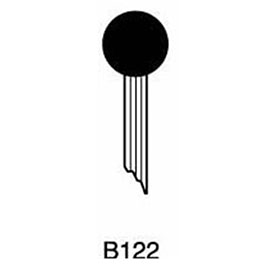

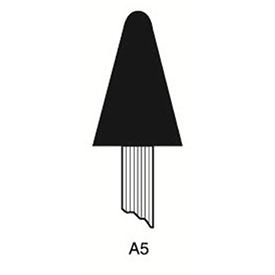

Standard Abrasives 877039, Unitized Mounted Point, 632 B121 x 1/8 in, 3M 7010368370

$5.92

Factory Stock, 7-10 Day Leadtime

Our Standard Abrasives Unitized Mounted Point lightly deburrs, blends and finishes metal and plastic parts. Choose from many different shapes and sizes to match specific small parts with hard-to-reach areas. Unitized mounted points deburr and finish without altering the shape of the workpiece, and self-dress to continually expose fresh mineral during use for efficient operations.