-

×

3M 09099, Scotch-Brite Paint and Rust Stripper Large Area 9099NA, 7010375230

6 × $7.45

3M 09099, Scotch-Brite Paint and Rust Stripper Large Area 9099NA, 7010375230

6 × $7.45 -

×

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,598.86

Dynabrade 14360 Pneumatic Pipe Belt Finisher

1 × $1,598.86 -

×

3M 26557, Cloth Belt 341D, P180 X-weight, 2 in x 48 in, Film-lok, Single-flex, 7010307963, 50 per case

50 × $3.15

3M 26557, Cloth Belt 341D, P180 X-weight, 2 in x 48 in, Film-lok, Single-flex, 7010307963, 50 per case

50 × $3.15 -

×

Dynabrade 58507 2-3/4" W x 7" L Dynabug II Orbital Sander, Non-Vacuum with Clips, .15 HP, 10,000 RPM, 3/32" Orbit

1 × $285.14

Dynabrade 58507 2-3/4" W x 7" L Dynabug II Orbital Sander, Non-Vacuum with Clips, .15 HP, 10,000 RPM, 3/32" Orbit

1 × $285.14 -

×

3M 34786, 663FC, 3/4" X 90", 70u, Diamond Trizact Belts 7100063667

1 × $300.00

3M 34786, 663FC, 3/4" X 90", 70u, Diamond Trizact Belts 7100063667

1 × $300.00 -

×

3M 27359, Cloth Belt 970DZ, 24 YN-weight, 25 in x 75 in, Film-lok, Single-flex, 7010361224, 2 per case

2 × $206.61

3M 27359, Cloth Belt 970DZ, 24 YN-weight, 25 in x 75 in, Film-lok, Single-flex, 7010361224, 2 per case

2 × $206.61 -

×

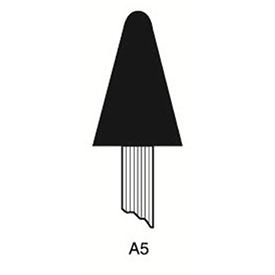

Dynabrade 78743 1/4" x 3/4"-W164 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $2.40

Dynabrade 78743 1/4" x 3/4"-W164 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $2.40 -

×

3M 29860, Sanding Screen, 120 grit, 12 in x 18 in, 7100160860

20 × $5.05

3M 29860, Sanding Screen, 120 grit, 12 in x 18 in, 7100160860

20 × $5.05 -

×

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

200 × $1.74

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

200 × $1.74 -

×

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

480 × $8.38

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

480 × $8.38 -

×

3M 01333, PSA Cloth Disc 348D, 60 X-weight, 3 in x NH, Die 300V, 7000118880

200 × $0.94

3M 01333, PSA Cloth Disc 348D, 60 X-weight, 3 in x NH, Die 300V, 7000118880

200 × $0.94 -

×

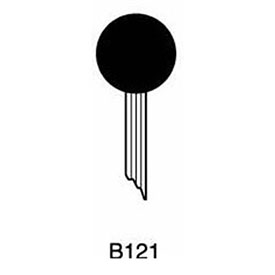

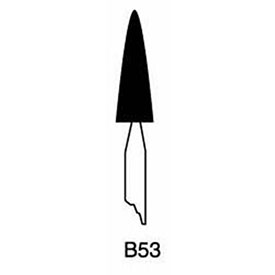

Dynabrade 78725 5/16" x 5/8"-B53 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46

Dynabrade 78725 5/16" x 5/8"-B53 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46

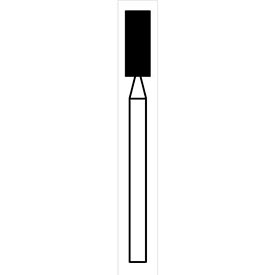

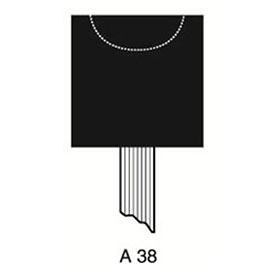

Standard Abrasives 877025, Unitized Mounted Point, 811 W183 x 1/8 in, 3M 7010366927

$4.85

Factory Stock, 7-10 Day Leadtime

Our Standard Abrasives Unitized Mounted Point lightly deburrs, blends and finishes metal and plastic parts. Choose from many different shapes and sizes to match specific small parts with hard-to-reach areas. Unitized mounted points deburr and finish without altering the shape of the workpiece, and self-dress to continually expose fresh mineral during use for efficient operations.