-

×

Standard Abrasives 840137, Quick Change Surface Conditioning GP Disc, Coarse, TSM, 1 in, 7000121648, 50 per case

50 × $0.86

Standard Abrasives 840137, Quick Change Surface Conditioning GP Disc, Coarse, TSM, 1 in, 7000121648, 50 per case

50 × $0.86 -

×

Dynabrade 15360 Dynafile III Abrasive Belt Machine for 24" Belts

1 × $896.53

Dynabrade 15360 Dynafile III Abrasive Belt Machine for 24" Belts

1 × $896.53 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $431.21

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $431.21 -

×

3M 26515, Cloth Belt 341D, P180 X-weight, 6 in x 48 in, Film-lok, Single-flex, 7000118795, 20 per case

20 × $9.13

3M 26515, Cloth Belt 341D, P180 X-weight, 6 in x 48 in, Film-lok, Single-flex, 7000118795, 20 per case

20 × $9.13 -

×

3M 49833, Multi-Purpose Duct Tape 3900, Black, 48 mm x 54.8 m, 7.7 mil, 7000148383

24 × $17.21

3M 49833, Multi-Purpose Duct Tape 3900, Black, 48 mm x 54.8 m, 7.7 mil, 7000148383

24 × $17.21 -

×

Dynabrade 58037 1-1/4" Dia. Right Angle Mini-Orbital Sander, 12K RPM, .4 HP, Front Exhaust

1 × $874.65

Dynabrade 58037 1-1/4" Dia. Right Angle Mini-Orbital Sander, 12K RPM, .4 HP, Front Exhaust

1 × $874.65 -

×

Dynabrade 79151 1" W x 24" L 60 Grit DynaCut Premium Ceramic Belt, 50/pack

50 × $4.74

Dynabrade 79151 1" W x 24" L 60 Grit DynaCut Premium Ceramic Belt, 50/pack

50 × $4.74 -

×

3M 14725, Foam and Fabric Spray Adhesive 24, Orange, 16 fl oz Can (Net Wt 13.8 oz), 7100179450, 12/Case

12 × $9.49

3M 14725, Foam and Fabric Spray Adhesive 24, Orange, 16 fl oz Can (Net Wt 13.8 oz), 7100179450, 12/Case

12 × $9.49 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

3M 07958, Sanding Screen, 80 Grit, 7-7/8 in x 3/16 in, 7100160277

40 × $2.21

3M 07958, Sanding Screen, 80 Grit, 7-7/8 in x 3/16 in, 7100160277

40 × $2.21 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

Dynabrade 69522 Housing for 69500, 5,000 RPM

1 × $77.04

Dynabrade 69522 Housing for 69500, 5,000 RPM

1 × $77.04 -

×

3M 25140, Scotch-Weld Threadlocker TL43, Blue, 250 mL Bottle, 7100039221, 2/case

2 × $126.95

3M 25140, Scotch-Weld Threadlocker TL43, Blue, 250 mL Bottle, 7100039221, 2/case

2 × $126.95 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 60u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 60u

12 × $7.60 -

×

Standard Abrasives 840338, Quick Change Surface Conditioning GP Disc, A/O Medium, TSM, MAR, 2 in, Die QS200PM, 7000121650, 50/case

50 × $1.36

Standard Abrasives 840338, Quick Change Surface Conditioning GP Disc, A/O Medium, TSM, MAR, 2 in, Die QS200PM, 7000121650, 50/case

50 × $1.36 -

×

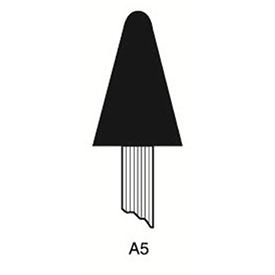

Dynabrade 78748 3/4" x 1-1/8"-A5 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $4.02

Dynabrade 78748 3/4" x 1-1/8"-A5 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $4.02 -

×

3M 94717, Cubitron ll Cloth Belt 947A, 80+ X-weight, 1 in x 30 in, Fabri-lok, Single-flex, 7010294445, 200 per case

200 × $3.73

3M 94717, Cubitron ll Cloth Belt 947A, 80+ X-weight, 1 in x 30 in, Fabri-lok, Single-flex, 7010294445, 200 per case

200 × $3.73 -

×

Standard Abrasives 843937, Quick Change Surface Conditioning GP Disc, 2560593, A/O Coarse, TSM, Brown, 7 in x 5/8"-11, 7000121657, 10/case

10 × $9.62

Standard Abrasives 843937, Quick Change Surface Conditioning GP Disc, 2560593, A/O Coarse, TSM, Brown, 7 in x 5/8"-11, 7000121657, 10/case

10 × $9.62 -

×

3M 97419, Aluminum Foil Tape 3380, Silver, 48 mm x 45 m, 3.25 mil, 7000049613

24 × $16.94

3M 97419, Aluminum Foil Tape 3380, Silver, 48 mm x 45 m, 3.25 mil, 7000049613

24 × $16.94 -

×

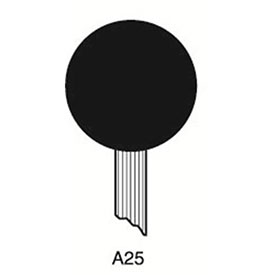

Dynabrade 78750 1" x 1"-A25 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $3.27

Dynabrade 78750 1" x 1"-A25 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $3.27

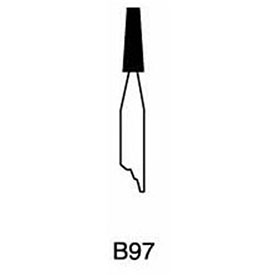

Standard Abrasives 877025, Unitized Mounted Point, 811 W183 x 1/8 in, 3M 7010366927

$4.85

Factory Stock, 7-10 Day Leadtime

Our Standard Abrasives Unitized Mounted Point lightly deburrs, blends and finishes metal and plastic parts. Choose from many different shapes and sizes to match specific small parts with hard-to-reach areas. Unitized mounted points deburr and finish without altering the shape of the workpiece, and self-dress to continually expose fresh mineral during use for efficient operations.