-

×

3M 29827, Sanding Screen, 120 Grit, 19 in x NH, 7100160249

22 × $8.00

3M 29827, Sanding Screen, 120 Grit, 19 in x NH, 7100160249

22 × $8.00 -

×

3M 25705, Scotch-Brite Roloc Surface Conditioning Disc, SC-DR, A/O Medium, TR, 3/4 in, 7000120983, 200/case

200 × $0.89

3M 25705, Scotch-Brite Roloc Surface Conditioning Disc, SC-DR, A/O Medium, TR, 3/4 in, 7000120983, 200/case

200 × $0.89 -

×

3M 87147, PSA Cloth Disc 777F, 5 x NH, 36 YF-weightt, 7010308524

250 × $3.18

3M 87147, PSA Cloth Disc 777F, 5 x NH, 36 YF-weightt, 7010308524

250 × $3.18 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 9u

36 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 9u

36 × $7.60 -

×

3M 25138, Scotch-Weld Threadlocker TL43, Blue, 10 mL Bottle, 7100039219, 10/case

10 × $13.32

3M 25138, Scotch-Weld Threadlocker TL43, Blue, 10 mL Bottle, 7100039219, 10/case

10 × $13.32 -

×

3M 29859, Sanding Screen, 100 grit, 12 in x 18 in, 7100160861

20 × $5.45

3M 29859, Sanding Screen, 100 grit, 12 in x 18 in, 7100160861

20 × $5.45 -

×

3M 09413, Scotch-Brite Contour Surface Paint and Varnish Remover 9413NA, 7000052005

10 × $5.79

3M 09413, Scotch-Brite Contour Surface Paint and Varnish Remover 9413NA, 7000052005

10 × $5.79 -

×

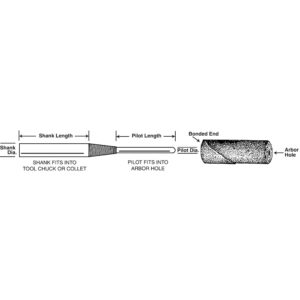

Standard Abrasives 713638, Cartridge RoII Mandrel, 3/32 in x 3/4 in x 1/8 in x 1 in x 2-3/4 in CM-2B, 7010294964

5 × $4.32

Standard Abrasives 713638, Cartridge RoII Mandrel, 3/32 in x 3/4 in x 1/8 in x 1 in x 2-3/4 in CM-2B, 7010294964

5 × $4.32 -

×

3M 29830, Sanding Screen, 60 Grit, 19 in x NH, 7100160131

12 × $13.48

3M 29830, Sanding Screen, 60 Grit, 19 in x NH, 7100160131

12 × $13.48 -

×

3M 97956, Super 77 CA Multipurpose Spray Adhesive, Low VOC <25%, Clear, 24 fl oz Can, 7100014109, 12/Case

12 × $16.85

3M 97956, Super 77 CA Multipurpose Spray Adhesive, Low VOC <25%, Clear, 24 fl oz Can, 7100014109, 12/Case

12 × $16.85 -

×

3M 20227, Scotch-Seal Metal Sealant 2084, Silver, 5 oz Tube, 7000046343, 36/Case

36 × $23.01

3M 20227, Scotch-Seal Metal Sealant 2084, Silver, 5 oz Tube, 7000046343, 36/Case

36 × $23.01 -

×

Dynabrade 78744 1" x 1/8"-W215 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $6.75

Dynabrade 78744 1" x 1/8"-W215 DynaFire A/O Mounted Point, Vitrified, 5/pack

5 × $6.75

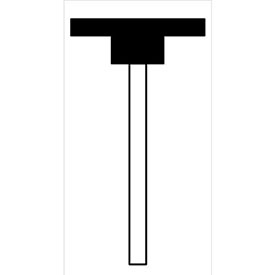

Standard Abrasives 877025, Unitized Mounted Point, 811 W183 x 1/8 in, 3M 7010366927

$4.85

Factory Stock, 7-10 Day Leadtime

Our Standard Abrasives Unitized Mounted Point lightly deburrs, blends and finishes metal and plastic parts. Choose from many different shapes and sizes to match specific small parts with hard-to-reach areas. Unitized mounted points deburr and finish without altering the shape of the workpiece, and self-dress to continually expose fresh mineral during use for efficient operations.