-

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

3 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

3 × $9.18 -

×

ACS Diamond Cloth Belt, CX1250 3" X 90" 45U

2 × $171.30

ACS Diamond Cloth Belt, CX1250 3" X 90" 45U

2 × $171.30 -

×

3M 45557, Cubitron ll Cloth Belt 784F, 60+ YF-weight, 2 in x 72 in, Film-lok, Single-flex, 7010299100, 50 per case

50 × $9.53

3M 45557, Cubitron ll Cloth Belt 784F, 60+ YF-weight, 2 in x 72 in, Film-lok, Single-flex, 7010299100, 50 per case

50 × $9.53 -

×

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $688.35

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $688.35 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

9 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

9 × $43.00 -

×

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

2 × $80.58

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

2 × $80.58 -

×

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

2 × $33.40

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

2 × $33.40 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

ACS Diamond Cloth Belt, CX1250 3" X 30" 125U

2 × $57.10

ACS Diamond Cloth Belt, CX1250 3" X 30" 125U

2 × $57.10 -

×

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26 -

×

3M 88869, PSA Cloth Disc 777F, 36 YF-weight, 12 in x NH, Die 1200B, 7000120240

10 × $18.06

3M 88869, PSA Cloth Disc 777F, 36 YF-weight, 12 in x NH, Die 1200B, 7000120240

10 × $18.06 -

×

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67 -

×

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $963.87

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $963.87 -

×

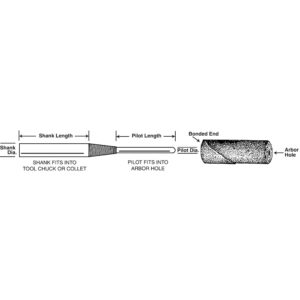

Standard Abrasives 713638, Cartridge RoII Mandrel, 3/32 in x 3/4 in x 1/8 in x 1 in x 2-3/4 in CM-2B, 7010294964

5 × $4.32

Standard Abrasives 713638, Cartridge RoII Mandrel, 3/32 in x 3/4 in x 1/8 in x 1 in x 2-3/4 in CM-2B, 7010294964

5 × $4.32 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58 -

×

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

36 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

36 × $9.52 -

×

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39 -

×

3M 66165, Wind Protection Tape Edge Sealer W2600, 50 ml (1.7 fluid ounce), 7100008766, 12/Case

12 × $69.98

3M 66165, Wind Protection Tape Edge Sealer W2600, 50 ml (1.7 fluid ounce), 7100008766, 12/Case

12 × $69.98 -

×

3M 76790, Roloc Disc 361F, 60 YF-weight, TS, 2 in, Die RS200P, 7010300088

200 × $1.13

3M 76790, Roloc Disc 361F, 60 YF-weight, TS, 2 in, Die RS200P, 7010300088

200 × $1.13 -

×

3M 50216, Temflex Cotton Friction Tape 1755, 3/4 in x 82-1/2 ft, Black, 7010297809

60 × $10.08

3M 50216, Temflex Cotton Friction Tape 1755, 3/4 in x 82-1/2 ft, Black, 7010297809

60 × $10.08 -

×

Standard Abrasives 707505, PSA A/O Disc, 12 in x NH, 40 Grit, 7010369974

10 × $6.35

Standard Abrasives 707505, PSA A/O Disc, 12 in x NH, 40 Grit, 7010369974

10 × $6.35 -

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,493.91

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,493.91 -

×

3M 17098, Hood Assembly with Sealed Seams Inner Shroud and Premium Head Suspension S-857, 7000002350, 1 EA/Case

1 × $185.27

3M 17098, Hood Assembly with Sealed Seams Inner Shroud and Premium Head Suspension S-857, 7000002350, 1 EA/Case

1 × $185.27 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75 -

×

3M 85314, Aluminum Foil Tape 425, Silver, 19 mm x 55 m, 4.6 mil, 7100053636

48 × $31.77

3M 85314, Aluminum Foil Tape 425, Silver, 19 mm x 55 m, 4.6 mil, 7100053636

48 × $31.77 -

×

Standard Abrasives 701616, PSA A/O Disc, 12 in x NH, 50, 7010369977

10 × $6.01

Standard Abrasives 701616, PSA A/O Disc, 12 in x NH, 50, 7010369977

10 × $6.01 -

×

3M 88904, PSA Cloth Disc 348D, 50 X-weight, 12 in x NH, Die 1200B, 7000118897

10 × $7.92

3M 88904, PSA Cloth Disc 348D, 50 X-weight, 12 in x NH, Die 1200B, 7000118897

10 × $7.92 -

×

3M 55053, Cubitron II Cloth Belt 984F, 80+ YF-weight, 1/2 in x 12 in, Fabri-lok, Single-flex, 7000119518, 200 per case

200 × $2.77

3M 55053, Cubitron II Cloth Belt 984F, 80+ YF-weight, 1/2 in x 12 in, Fabri-lok, Single-flex, 7000119518, 200 per case

200 × $2.77 -

×

3M 88906, PSA Cloth Disc 348D, 36 X-weight, 12 in x NH, Die 1200B, 7000118898

10 × $8.91

3M 88906, PSA Cloth Disc 348D, 36 X-weight, 12 in x NH, Die 1200B, 7000118898

10 × $8.91 -

×

3M 19772, Utility Cloth Sheet 314D, 9 in x 11 in P80 J-weight, 7000000359

250 × $1.45

3M 19772, Utility Cloth Sheet 314D, 9 in x 11 in P80 J-weight, 7000000359

250 × $1.45 -

×

3M 94700, Cubitron ll Cloth Belt 947A, 60+ X-weight, 1/4 in x 24 in, Fabri-lok, Single-flex, 7010360589, 200 per case

1 × $2.40

3M 94700, Cubitron ll Cloth Belt 947A, 60+ X-weight, 1/4 in x 24 in, Fabri-lok, Single-flex, 7010360589, 200 per case

1 × $2.40 -

×

3M 28719, Wheel Adapter Kit 28719, 1 in x 5/8-11 Internal, 7100050705

1 × $50.70

3M 28719, Wheel Adapter Kit 28719, 1 in x 5/8-11 Internal, 7100050705

1 × $50.70 -

×

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06 -

×

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

2 × $435.37

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

2 × $435.37 -

×

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

2 × $500.06

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

2 × $500.06 -

×

3M 83330, Cubitron II Fibre Disc 982CX Pro, 36+, 4 in x 5/8 in, Die 400FF, 7100242928

100 × $4.42

3M 83330, Cubitron II Fibre Disc 982CX Pro, 36+, 4 in x 5/8 in, Die 400FF, 7100242928

100 × $4.42 -

×

3M 11418, Roloc Disc 361F, P240 XF-weight, TR, 3 in, Die R300V, 7000045106

200 × $1.25

3M 11418, Roloc Disc 361F, P240 XF-weight, TR, 3 in, Die R300V, 7000045106

200 × $1.25 -

×

Standard Abrasives 717639, Aluminum Oxide Straight Cartridge Roll, 5/8 in x 2 in x 3/16 in 50, 7100115215

50 × $0.92

Standard Abrasives 717639, Aluminum Oxide Straight Cartridge Roll, 5/8 in x 2 in x 3/16 in 50, 7100115215

50 × $0.92 -

×

3M 45120, Cartridge RoII Mandrel, 3/32 in x 3/4 in x 1/4 in, 7010328349

25 × $4.11

3M 45120, Cartridge RoII Mandrel, 3/32 in x 3/4 in x 1/4 in, 7010328349

25 × $4.11 -

×

3M 07414, Hand Sanding Metal Finishing Pad 7414NA, 4.375 in x 11 in, Maroon Medium, 7010315820

10 × $1.77

3M 07414, Hand Sanding Metal Finishing Pad 7414NA, 4.375 in x 11 in, Maroon Medium, 7010315820

10 × $1.77

Science in the Service of U.S. Soldiers

We engineered our 3M Roto Peen Mandrel to deliver quick, efficient repair and maintenance to U.S. Army helicopters to components like rotors and rotor hubs in the field, our 3M Roto Peen Mandrel and its associated flap assembly allowed peening action using a die grinder or disc sander. In the early 1970s, the 3M Roto Peen Flap Assembly (or TC 330) was qualified and written into military specifications. It soon spread to other aerospace applications.

Used today primarily for aerospace applications, the mandrel comported with a flap assembly allows use of a die grinder or disc sander to perform captive shot peening to repair metal surfaces. The assembly consists of tungsten carbide shot bonded to a flexible polymeric flap gripped by the mandrels attached to the power tool. The spinning flap is held near the surface so that the captive shot hammers the metal surface with each revolution.

Portable, Able to Reach Small Areas and Large Components

Our 3M flap/mandrel assemblies provide convenient portability and are especially effective for precision in-service rework, manufacturing, repair of small areas, and peening holes with diameters down to 1/2 inch (12.7mm). Flaps can also be cut with scissors to peen confined areas or peen into areas with a radius down to 1/16 inch (1.6mm) .

Captive shot peening is used for repair or limited access work or when free shot cannot be tolerated. Having the shot used to peen metal surfaces in a captive flap allows for more control and greater access to areas that require this strengthening procedure.

Evolved from the days of blacksmiths hammering swords, peening is a process that utilizes compressive surface stress to strengthen metals, improving resistance to fatigue fracture and stress corrosion cracking. The aerospace industry has stringent peening specifications, in which adherence must frequently be documented. Off-spec peening can result in the failure of parts.

3M also provides Almen gauges to provide precise readings of strip deflections to measure peening intensities. Adopted by the SAE (Society of Automotive Engineers), the Almen Scale of Peen Intensity measures the curvature of a standardized steel strip when peened on one side.

Recommended Applications

- MRO in aerospace, military and small shop environments

- For parts that are too large to fit in a peening cabinet

- Parts that are subjected to mechanical rework and require rework

- Landing gear assemblies

- Wing structures

- Helicopter rotor hub

- Jet engine support members

- Peening after grinding

- Peening before plating

- Peening of surfaces subject to stress corrosion

- Peen straightening

- Peen forming

- Weld heat affect zone

- Bond testing